Twin-screw propelling device for ship

A technology of double propellers and propulsion devices, which is applied in the direction of ship propulsion, propulsion components, ship components, etc., and can solve problems such as unbalanced forces, increased rudder bearings, and affecting safe navigation of ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

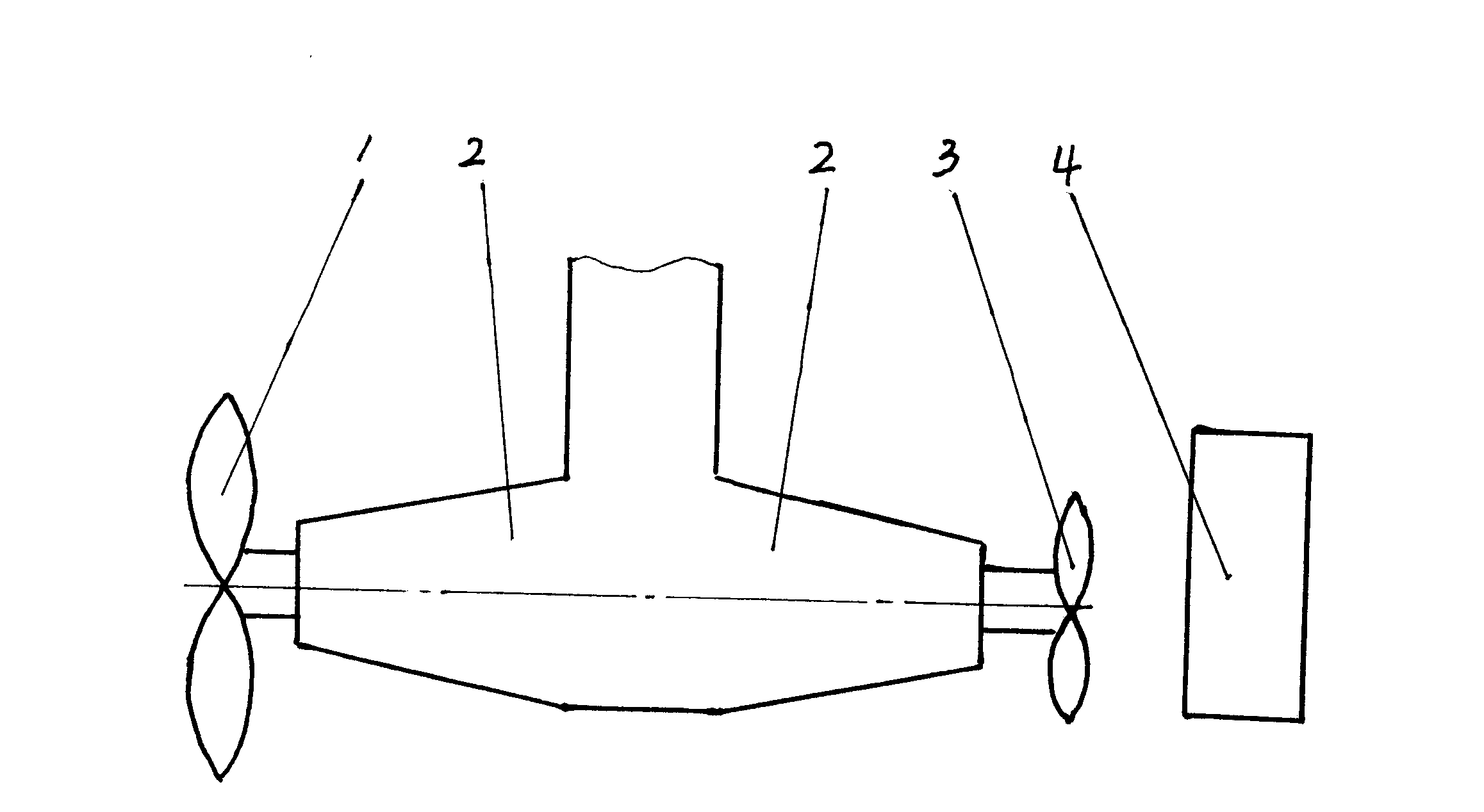

[0009] figure 1 Among them, the propeller seat 2 is fixedly connected to the hull, the main propeller 1 is installed at the front end of the propeller seat 2, the auxiliary propeller 3 is installed at the rear end of the propeller seat 2, the rudder blade 4 is behind the auxiliary propeller 3, and the rudder blade 4 passes through the rudder stock Rotatably installed on the hull (rudder stock is not shown in the figure), the axis of auxiliary propeller 3 coincides with the axis of main propeller 1, the diameter of auxiliary propeller 3 is less than the diameter of main propeller 1, the rotation of the blade on the auxiliary propeller 3 The direction of rotation is opposite to that of the blades on the main propeller 1. The main propeller 1 and the auxiliary propeller 3 are driven by respective transmissions (the transmission is not shown in the figure). During work, the rotation direction of the main propeller 1 is opposite to that of the auxiliary propeller 3. The propelled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com