Winch for online test of automatic cable arranging tension

An online testing and automatic rowing technology, applied in the direction of tension measurement, etc., can solve problems such as uneven cable rowing, inaccurate data, large surges, etc., and achieve the effect of uniform force and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] This embodiment provides an automatic cable tension on-line test winch, which assembles the cable mechanism and the winch into one, and can monitor the tension on the cable in real time during the working process to ensure the normal operation of the underwater equipment; The drive cylinder drives the cable pressing mechanism, which can ensure that the working cable on the reel is under constant pressure and keep the working cable evenly stressed when it is laid.

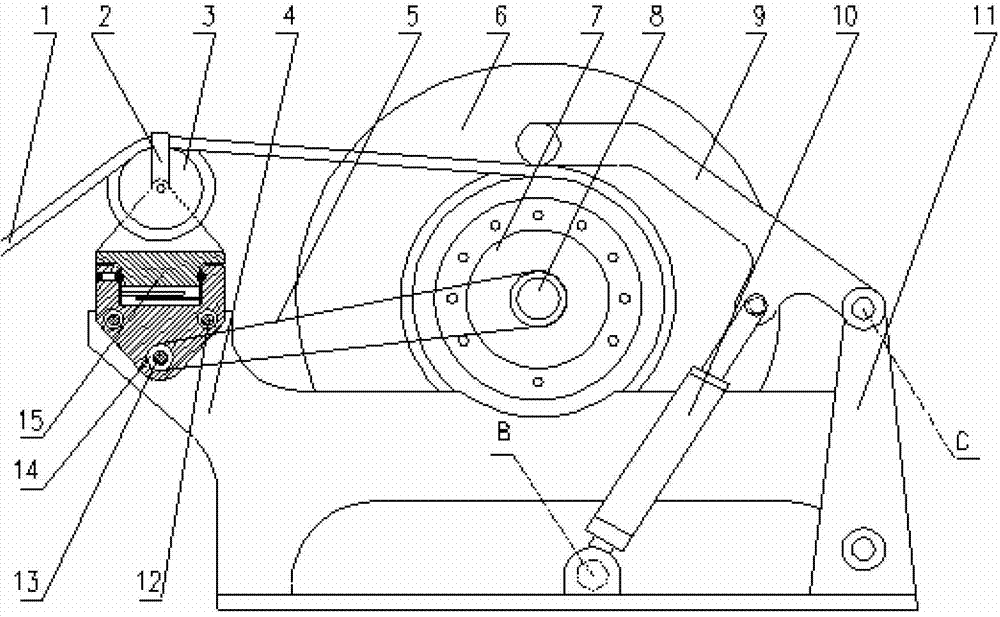

[0031] The overall structure of the winch is as follows figure 1 As shown, it includes: working cable 1, base 4, transmission chain 5, reel 6, motor 7, large sprocket 8, cable pressing mechanism, small sprocket 14, cable discharge mechanism 15 and control unit.

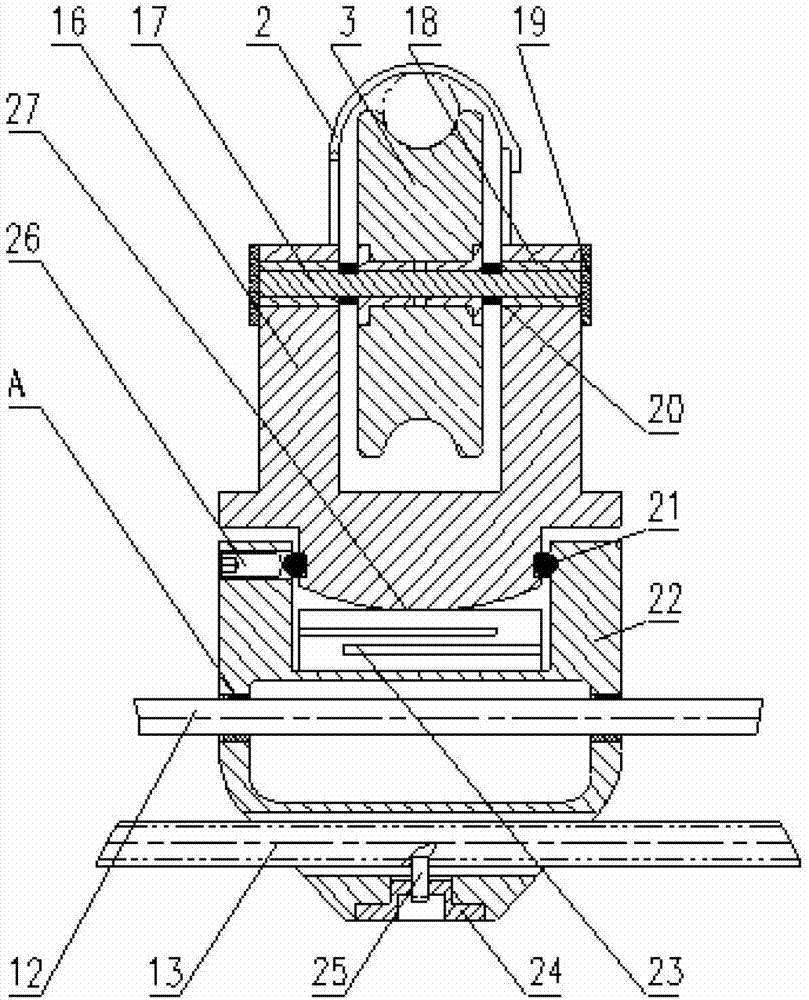

[0032] Wherein the structure of cable discharge mechanism 15 is as figure 2 As shown, it includes protective cover 2, roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com