DI (deionized) water supply system and application method thereof

A technology for water supply systems and water pumps, applied in water supply pipeline systems, water supply devices, water supply devices, etc., can solve problems such as cumbersome control and control operations of three-way valves, reduced bottom sealing, and impact on production and processing, and achieve high use and promotion value. Effects of reduced piping influence and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

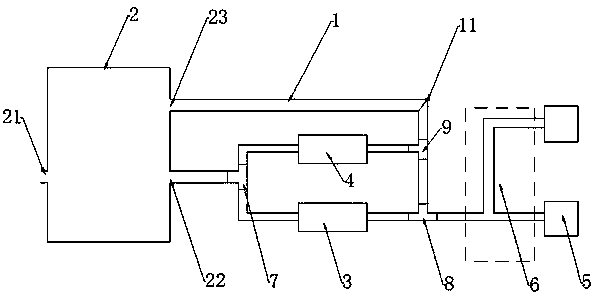

[0029] As shown in the figure, the present invention discloses a DI water supply system that can automatically eliminate the water hammer effect and its application method.

[0030] Specifically, a DI water supply system includes a DI water storage mechanism, a DI water pumping mechanism, and a DI water utilization mechanism, and the DI water storage mechanism, the DI water pumping mechanism, and the DI water utilization mechanism are connected by pipelines in sequence A return water pipeline 1 is connected between the DI water pumping mechanism and the DI water use mechanism, and the return water pipeline 1 communicates with the DI water storage mechanism.

[0031] The DI water storage mechanism is a water storage tank 2 , and a water inlet 21 , a water outlet 22 and a water return port 23 are opened on the side wall of the water storage tank 2 .

[0032] In this embodiment, the DI water pumping mechanism includes a first water pump 3 and a second water pump 4 , and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com