Preparation method of large-size optical fiber preform

An optical fiber preform and large-size technology, applied in the field of optical fiber manufacturing, can solve the problems of high cost of pure natural quartz sand, difficult to control the uniformity, and low deposition rate, so as to save wire drawing processing time and material cost, and facilitate large-scale production , Excellent effect of optical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

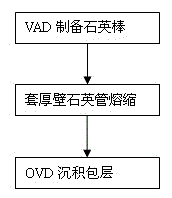

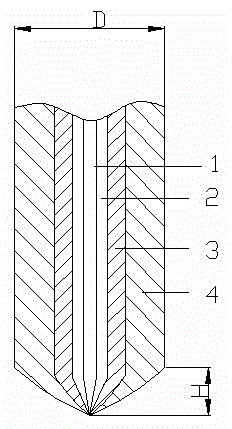

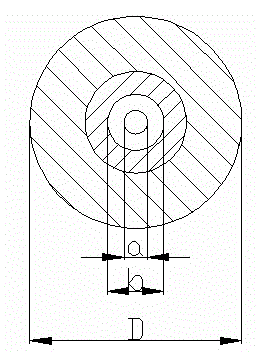

[0030] Embodiment 1: Matched cladding low water peak single-mode optical fiber prefabricated rod.

[0031] VAD is used to prepare transparent solid quartz rods, including the core layer and part of the cladding. After dehydration and sintering, the loose body prepared by VAD is transformed into a transparent solid quartz rod, and then undergoes shaping treatment. After shaping, the cladding / core layer The diameter ratio b / a is 2.9~3, the length of the effective part reaches 2 / 3 of the total length, and the fluctuation range of the diameter of the effective part is less than 4%, and the surface roughness of the transparent solid quartz rod is less than 20 μm. The quartz rod is fused with a high-purity thick-walled quartz tube set with an outer diameter of 45 mm, an inner diameter of 28 mm, and an inner surface roughness of less than 20 μm to form a quartz rod to obtain a primary optical fiber preform with a uniform structure. The hydroxyl content of the thick-walled tube is le...

Embodiment 2

[0032] Embodiment 2: a depressed-clad single-mode optical fiber prefabricated rod.

[0033] A transparent solid quartz rod is prepared by VAD, including a core layer and a partial cladding layer, the cladding layer contains F, and the cladding / core layer diameter ratio b / a of the transparent solid quartz rod is 2.4 after shaping. The quartz rod is fused with a high-purity thick-walled quartz tube set with an outer diameter of 45 mm, an inner diameter of 28 mm, and an inner surface roughness of less than 20 μm to form a quartz rod to obtain a primary optical fiber preform with a uniform structure. The hydroxyl content of the thick-walled tube is less than 100 ppb. Using the optical fiber preform as a target rod, SiO was deposited by external method (OVD) 2 After the outer cladding is deposited, it is sintered into a transparent optical fiber preform with a diameter of 150mm. One end of the preform is a suspended end. In order to facilitate wire drawing, the suspended end is ...

Embodiment 3

[0034] Embodiment 3: Low water peak anti-bending single-mode optical fiber prefabricated rod.

[0035]A transparent solid quartz rod was prepared by VAD, including a core layer and a partial cladding layer. After shaping, the core-cladding ratio b / a of the transparent solid quartz rod was 1.8. Melt and shrink the quartz rod with a high-purity thick-walled quartz tube with an outer diameter of 50 mm, an inner diameter of 30 mm, and an inner surface roughness less than or equal to 20 μm to form a quartz rod to obtain a primary optical fiber preform with a uniform structure. The thick-walled tube contains F and The hydroxyl content is less than 50ppb. Using the optical fiber preform as a target rod, SiO was deposited by external method (OVD) 2 After the outer cladding is deposited, it is sintered into a transparent optical fiber preform rod with a diameter of 200mm, and the diameter fluctuation of its effective part is less than 1mm. One end of the preform rod is a suspension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com