Method for preparing large-size optical fiber preform

An optical fiber preform, large-scale technology, applied in the field of optical fiber manufacturing, can solve the problems of complex manufacturing process, low deposition rate, and high geometric accuracy, and achieve the effects of flat and beautiful appearance, high deposition rate, and high deposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

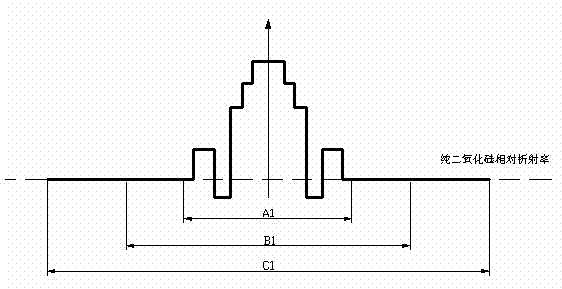

[0041] Embodiment 1: Large effective area and low water peak optical fiber preform.

[0042] According to the method of the invention, the quartz material containing Ge or F is deposited in the high-purity, low-hydroxyl quartz glass liner by PCVD. The hydroxyl content of the liner is less than 10ppb, and the waveguide structure in the core area is a segmented and stepped structure. Then the deposition tube was melted and shrunk at 1800° C. to 2100° C. to form a solid quartz core rod with a length of 1.2 m and a diameter of 25 mm.

[0043] Then use the VAD method to coat an appropriate amount of uniform quartz loose body on the outer surface of the quartz core rod and sinter it into a solid intermediate preform. The lower end of the target rod is suspended, and the upper end is clamped by the clamp 6 to rotate around the axis of the target rod at a speed of 5r / min, the lamp head of the VAD blowtorch does not move, the quartz rod moves vertically upwards, and the moving spee...

Embodiment 2

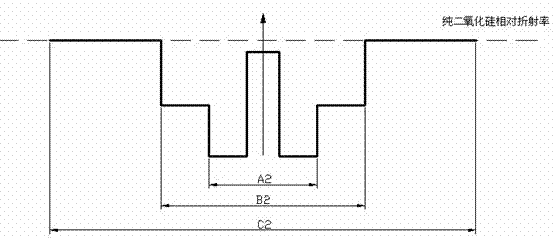

[0047] Embodiment 2: Radiation-resistant optical fiber preform.

[0048] According to the method of the invention, the MCVD method is used to deposit the F-containing core material in the high-purity, high-hydroxyl quartz glass liner. The hydroxyl content of the liner is higher than 1000ppm, and contains F, the relative refractive index difference of the liner is -0.36%, the relative refractive index difference of the inner cladding is the same as that of the liner, and the core waveguide structure is a step structure. The deposition tube was melted and shrunk at 1850° C. to 1950° C. into a solid quartz core rod, and the length of the quartz core rod was 1.5 m.

[0049] Then use the VAD method to coat an appropriate amount of uniform quartz loose body on the outer surface of the quartz rod. The lower end of the target rod is suspended in the air, and the upper end is clamped by the clamp 6 to rotate around the axis of the target rod at a speed of 120r / min. The lamp head of ...

Embodiment 3

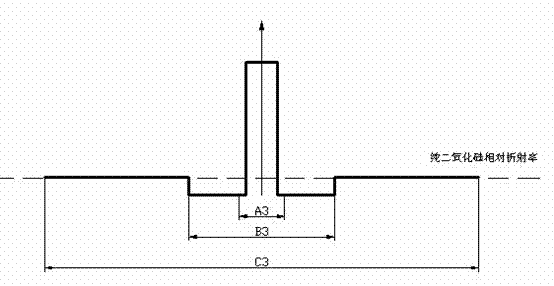

[0052] Embodiment 3: Single-mode optical fiber preform.

[0053] According to the method of the invention, the core material containing Ge is deposited in the high-purity, low-hydroxyl F-doped quartz glass liner by PCVD. The hydroxyl content of the liner is less than 10ppb, the relative refractive index difference is -0.1%, and the core waveguide structure is a stepped structure. Then, the deposition tube was melted and shrunk at 1800° C. to 2100° C. to form a solid quartz rod, and the length of the quartz rod was 1.1 m.

[0054] Then use the VAD method to coat an appropriate amount of uniform quartz loose body on the outer surface of the quartz rod and sinter it into a solid intermediate preform rod. The lower end of the target rod is suspended in the air, and the upper end is clamped by the clamp 6 to rotate around the axis of the target rod at a speed of 70r / min. , the lamp head of the VAD blowtorch does not move, and the quartz rod moves vertically upwards at a moving r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com