Preparation method of double-pulse plating solution of single metal Au, Sn and Au-Sn alloy soldering flux

A double-pulse, single-metal technology, applied in the field of solder preparation, can solve the problems of many additives in the plating solution, large internal stress of the plating layer, and fast plating rate, and achieve the effects of less pores, uniform thickness of the plating layer, and moderate electrodeposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

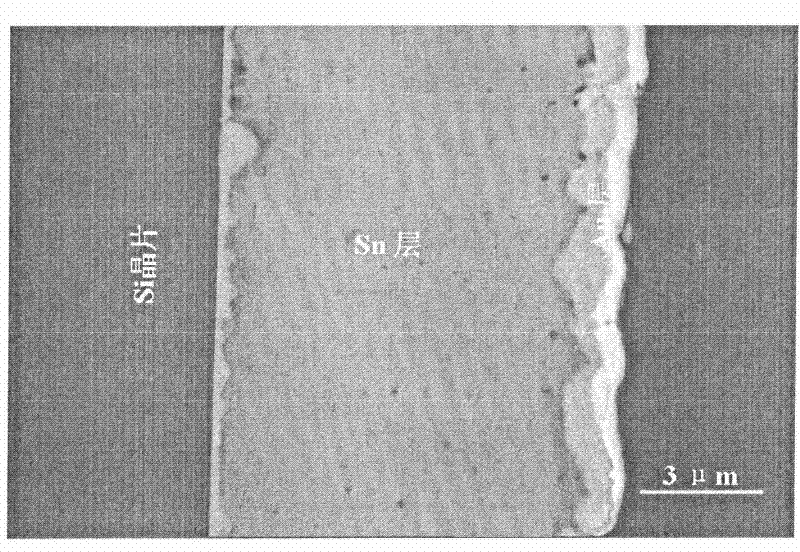

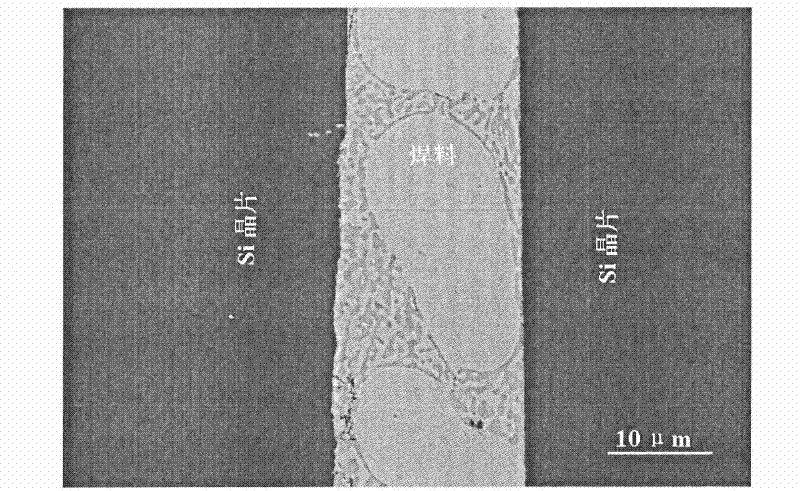

[0028] Embodiment 1: the preparation of the Au-Sn alloy soft solder that is rich in Sn

[0029] Potassium chloroaurate, sodium sulfite and triammonium citrate are used for electroplating Au single metal layer. Dissolve 3.4g of triammonium citrate in 50ml of deionized water, stir until completely dissolved, add 0.46g of potassium chloroaurate, stir for 20 minutes until completely dissolved, then add 0.72g of sodium sulfite, and stir until completely dissolved to obtain Light yellow and transparent Au electroplating solution; tin protochloride dihydrate and triammonium citrate are used for electroplating Sn single metal layer. Dissolve 5.4g of triammonium citrate in 50ml of deionized water, stir until completely dissolved, add 2.45g of stannous chloride dihydrate, stir for 15 minutes until completely dissolved, then add 0.1g of gelatin, stir until completely dissolved, that is A colorless and transparent Sn electroplating solution was obtained. Chemicals were of analytical or ...

Embodiment 2

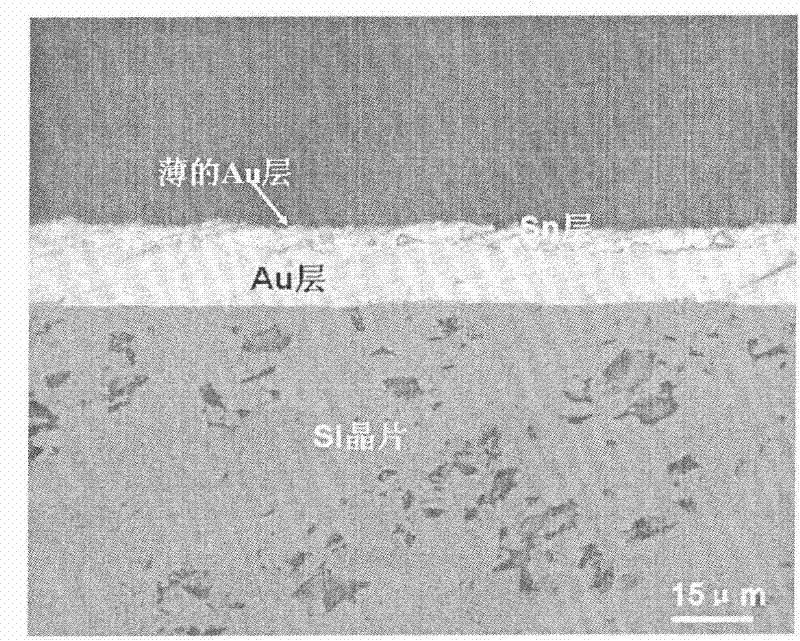

[0033] Embodiment 2: the preparation of the Au-Sn alloy hard solder that is rich in Au

[0034] Sodium chloroaurate, sodium sulfite and triammonium citrate are selected for electroplating Au single metal layer. Dissolve 3.4g of triammonium citrate in 50ml of distilled water, stir until completely dissolved, then add 0.44g of sodium chloroaurate, stir for 20 minutes until completely dissolved, then add 0.73g of sodium sulfite, stir until completely dissolved, and obtain shallow Yellow transparent Au electroplating solution; tin protochloride dihydrate and sodium citrate are used for electroplating Sn single metal layer. Dissolve 6.7g of sodium citrate in 50ml of distilled water, stir until completely dissolved, then add 2.45g of stannous chloride dihydrate, stir for 15 minutes until completely dissolved, then add 0.1g of gelatin, stir until completely dissolved, and obtain Color transparent Sn plating solution. Chemicals were of analytical or chemical purity. The prepared Au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com