Ceramic handrail automatic glaze pouring method and system

A railing and ceramic technology, applied in the field of ceramic glazing, can solve the problems of low efficiency, a large amount of manpower, and difficult automatic glazing, and achieve the effects of improving quality and efficiency, eliminating physical burden, and saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

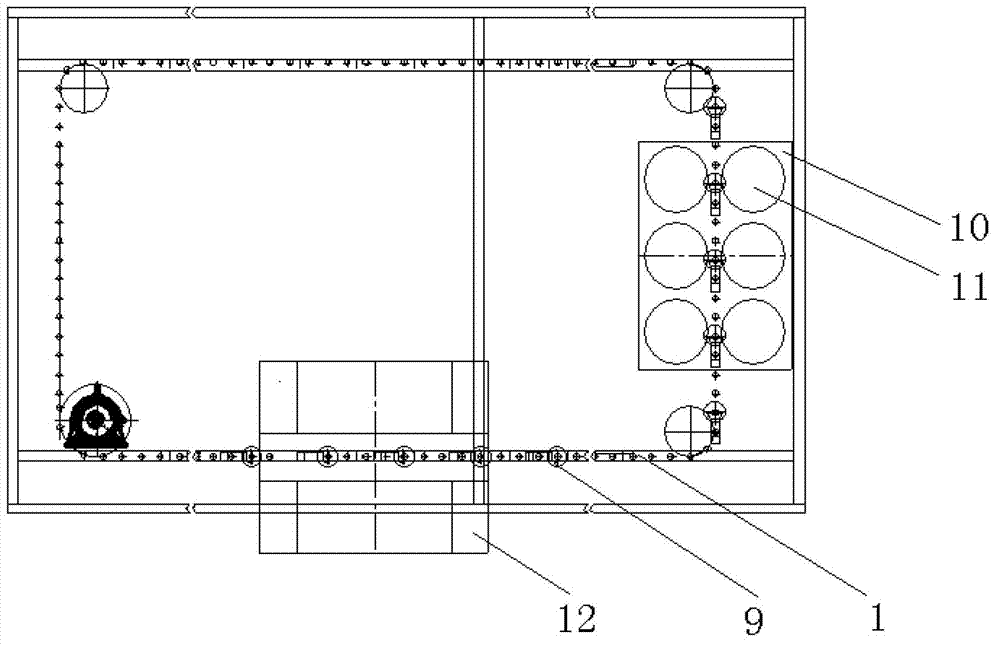

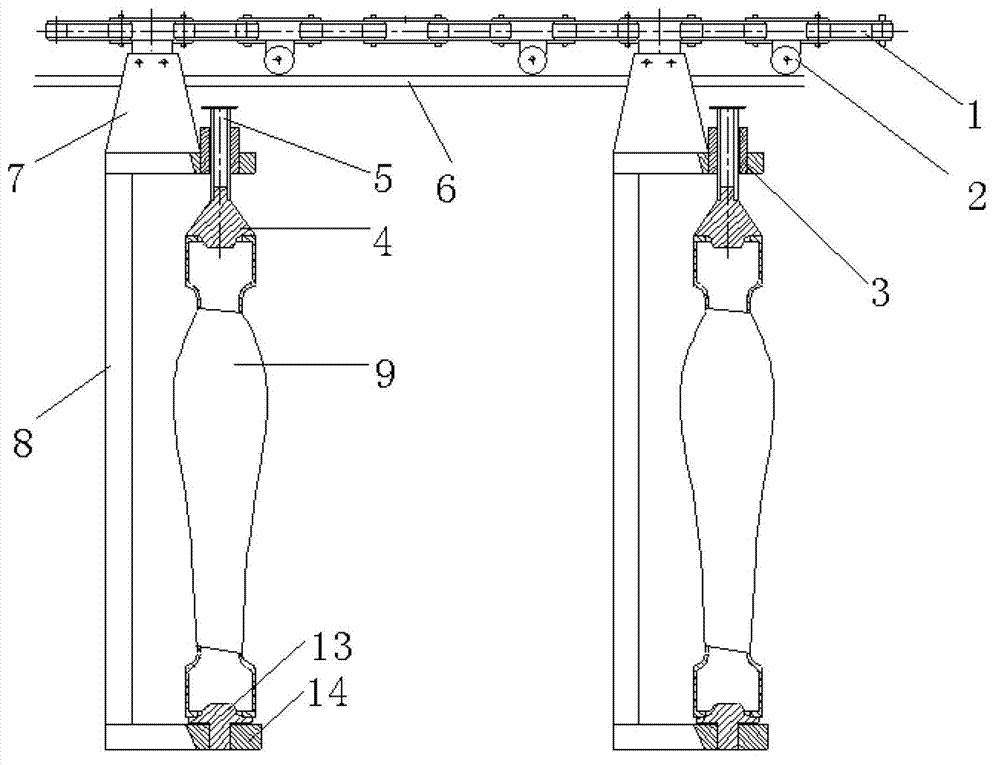

[0018] Such as figure 1 , 2 As shown, the automatic glazing method for ceramic balustrades includes the following process steps: firstly slide the casing 5 upwards at the blank placing station, the positioning plug 14 also rises, put the ceramic balustrade blank 9 into the bracket 8, and align the lower part with the positioning plug Two 13, slide positioning plug one 4 downwards, ceramic railing body 9 is fixed on the support; start the ceramic railing automatic glazing production line, be positioned at the chain 1 transmission above the bracket, drive the ceramic railing body 9 on the bracket 8 to pass through double A billet sweeping device 10 with a row of counterrotating and sweeping rows 11; the ceramic railing body 9 passes through the billet glaze spraying device 12 along with the transmission of the chain 1, and the four glaze water nozzles spray glaze on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com