Waveform mild steel energy dissipation support

An energy-consuming support and waveform technology, which is used in building components, earthquake-proof and other directions to achieve good seismic performance, reasonable plastic distribution, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

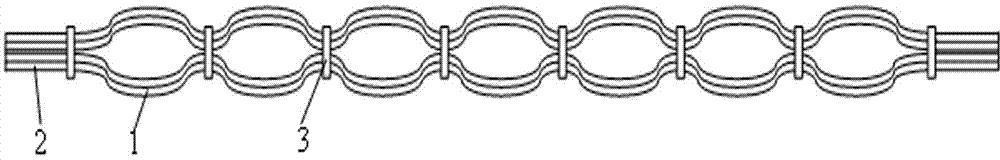

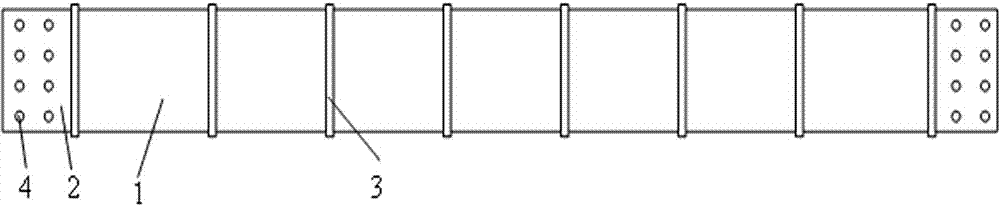

[0016] Such as figure 1 , 2 The shown corrugated mild steel energy dissipation support of the present invention includes: a laminated corrugated mild steel plate 1, a fixing part 2 and a steel hoop 3, and the laminated corrugated mild steel plate 1 is a large structure made of at least two layers of mild steel plates. The wave portion and the small wave portion are composed of the large wave portion and the small wave portion alternately and in opposite directions. Two laminated corrugated soft steel plates 1 are symmetrically arranged, and the small wave portions are in contact with each other, and each small wave portion is provided with a steel hoop 3; both ends of the laminated corrugated soft steel plate 1 symmetrically arranged are formed by connecting the wavelet part and the fixed part 2. The fixing part 2 is provided with a bolt hole 4; it is connected with the beam-column member by bolts to form a diagonal support, a herringbone support or a cross support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com