Mini vacuum pump

A technology of miniature vacuum pumps and shells, which is applied in the direction of pumps, pumps with flexible working elements, and liquid variable capacity machinery, etc., which can solve the problems of large operating current and output power of motors, energy consumption, and large operating noise of micro air pumps. Achieve the effects of reduced operating current, low energy consumption, and good vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

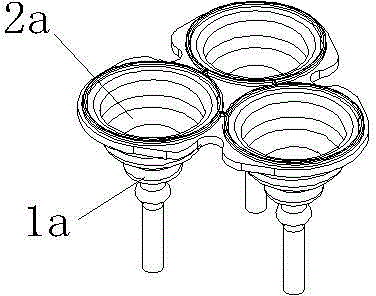

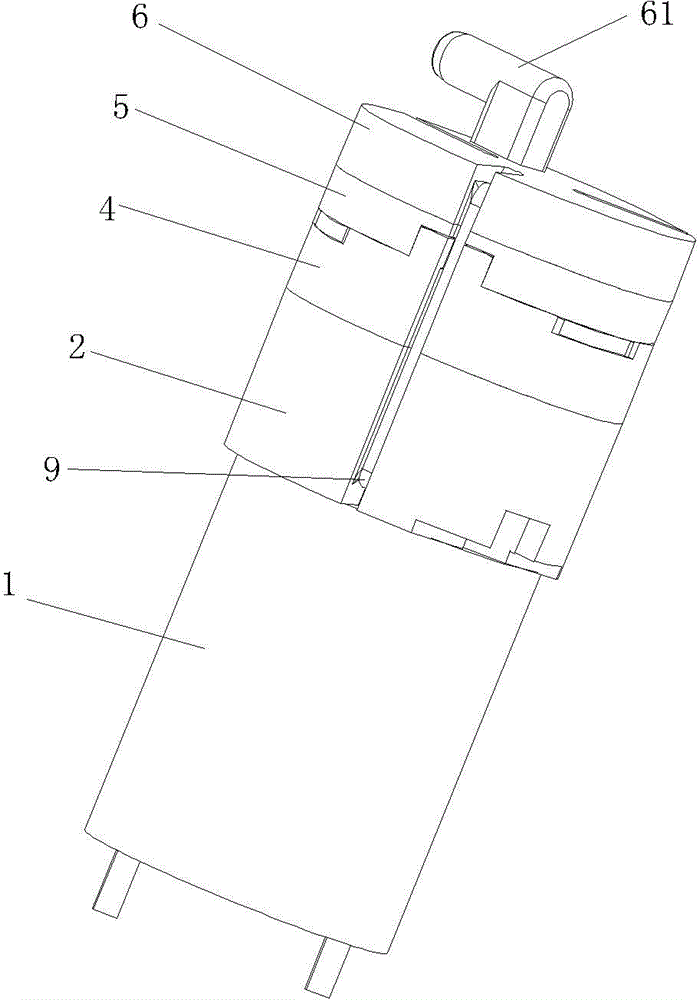

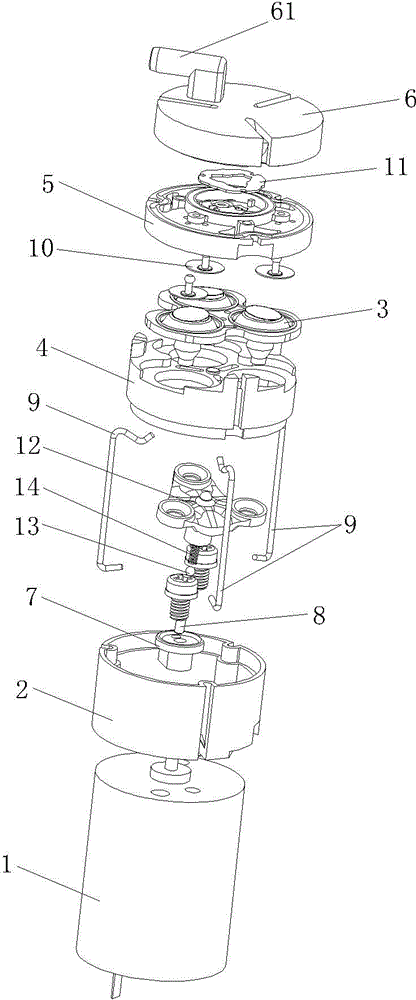

[0040] Figure 1 to Figure 19As shown, a miniature vacuum pump includes a motor 1, a housing 2, an air bag 3 with three bell-shaped bodies 31, an air bag seat 4, a valve seat 5, an upper cover 6 with a suction pipe 61, and the motor 1 is fixed on the shell. The bottom surface of the body 2, the drive shaft of the motor 1 extends into the housing 2, a runner 7 is fixed on the drive shaft of the motor 1, and the lower end of a pendulum shaft 8 is inserted on the runner 7, and the axis of the pendulum shaft 8 is in line with that of the runner 7. The central axes intersect, and the airbag seat 4, the valve seat 5 and the upper cover 6 are sequentially connected along the upper part of the housing 2 and fixed to each other. A corresponding draw-in groove, the draw-in groove is equipped with jumper 9 and housing 2, air bag seat 4, valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com