Sealing device with universal angle compensating tube

A technology of sealing device and compensation tube, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor sealing performance, achieve the effects of preventing mutual leakage, eliminating adverse effects, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

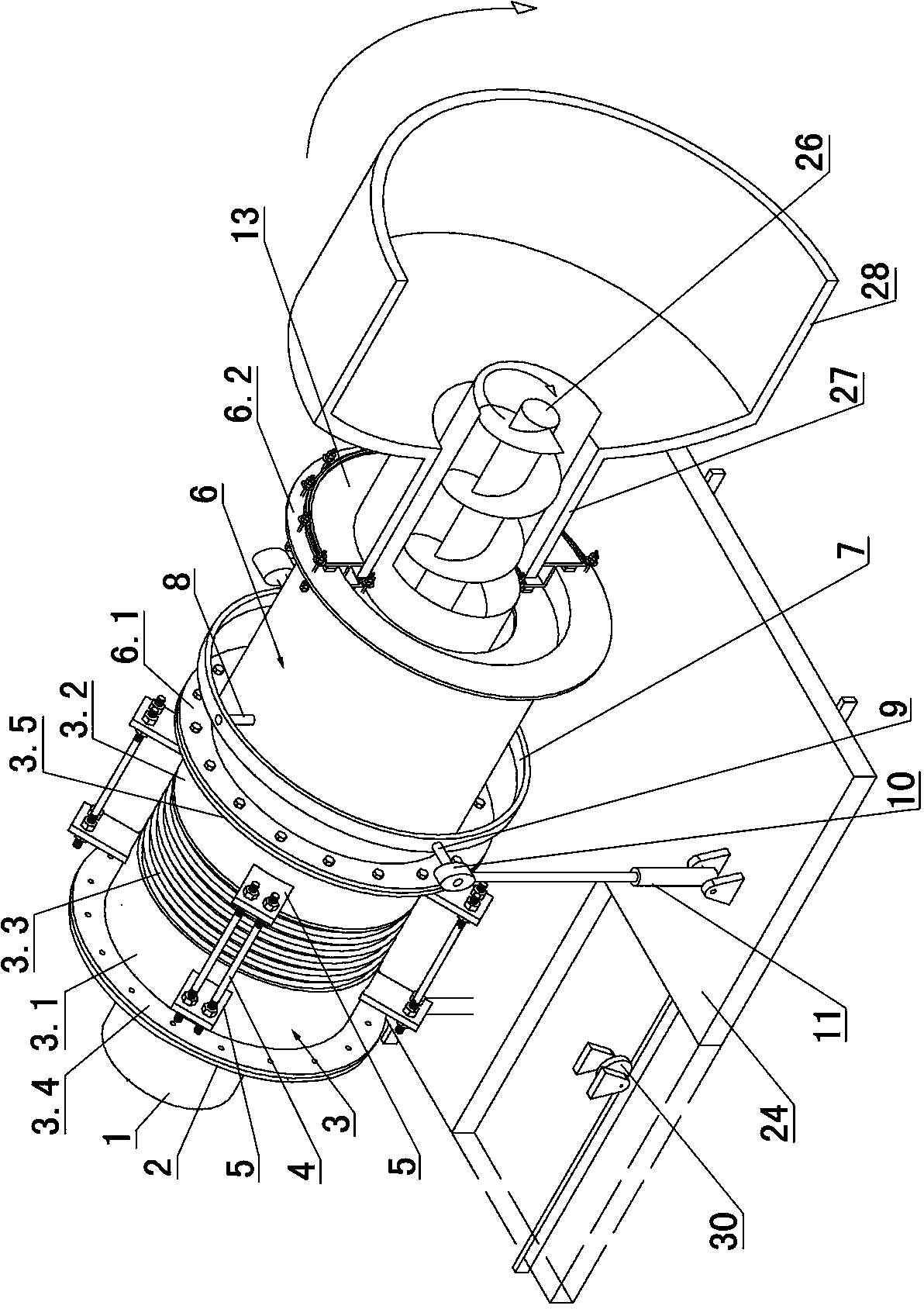

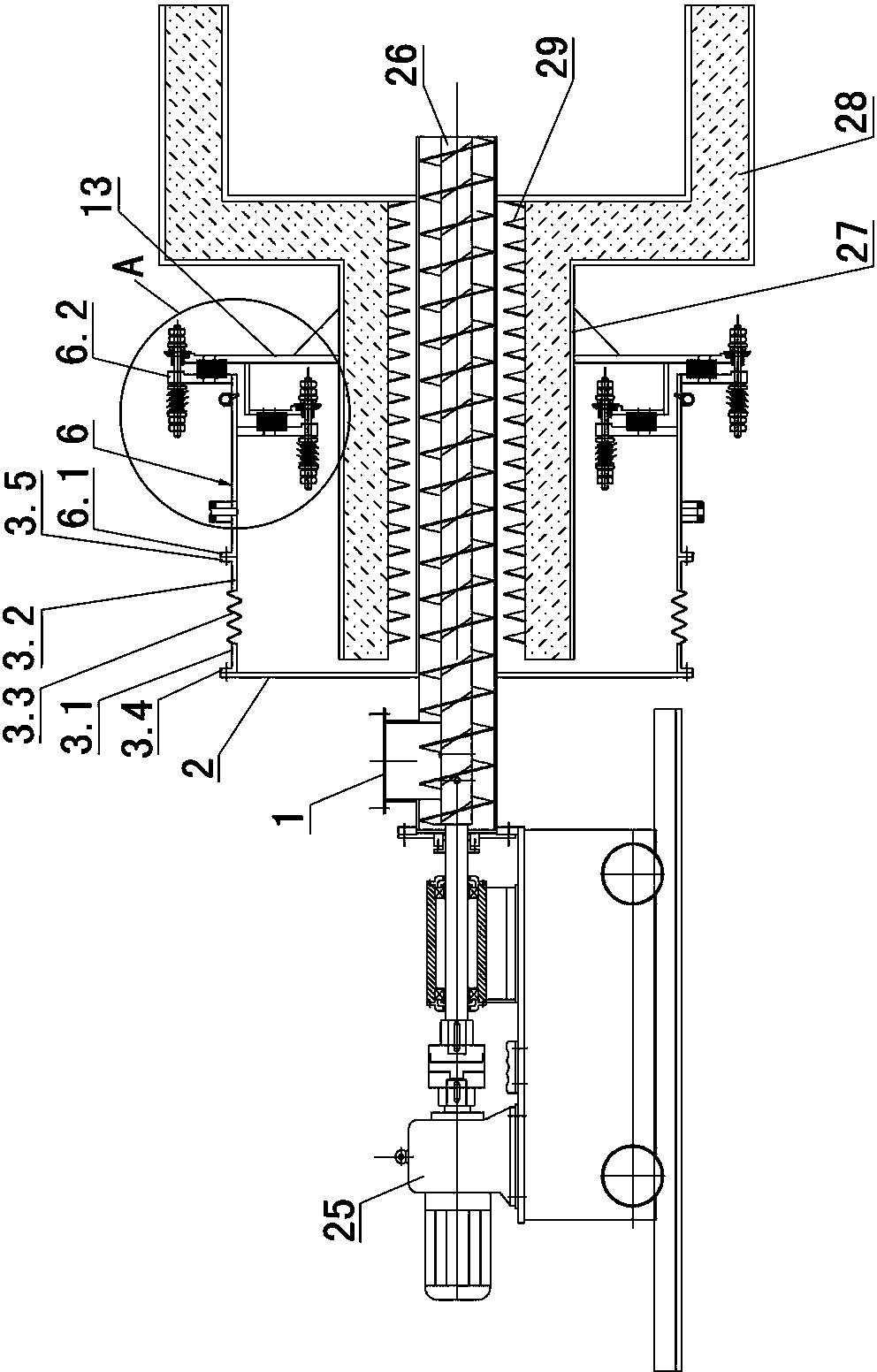

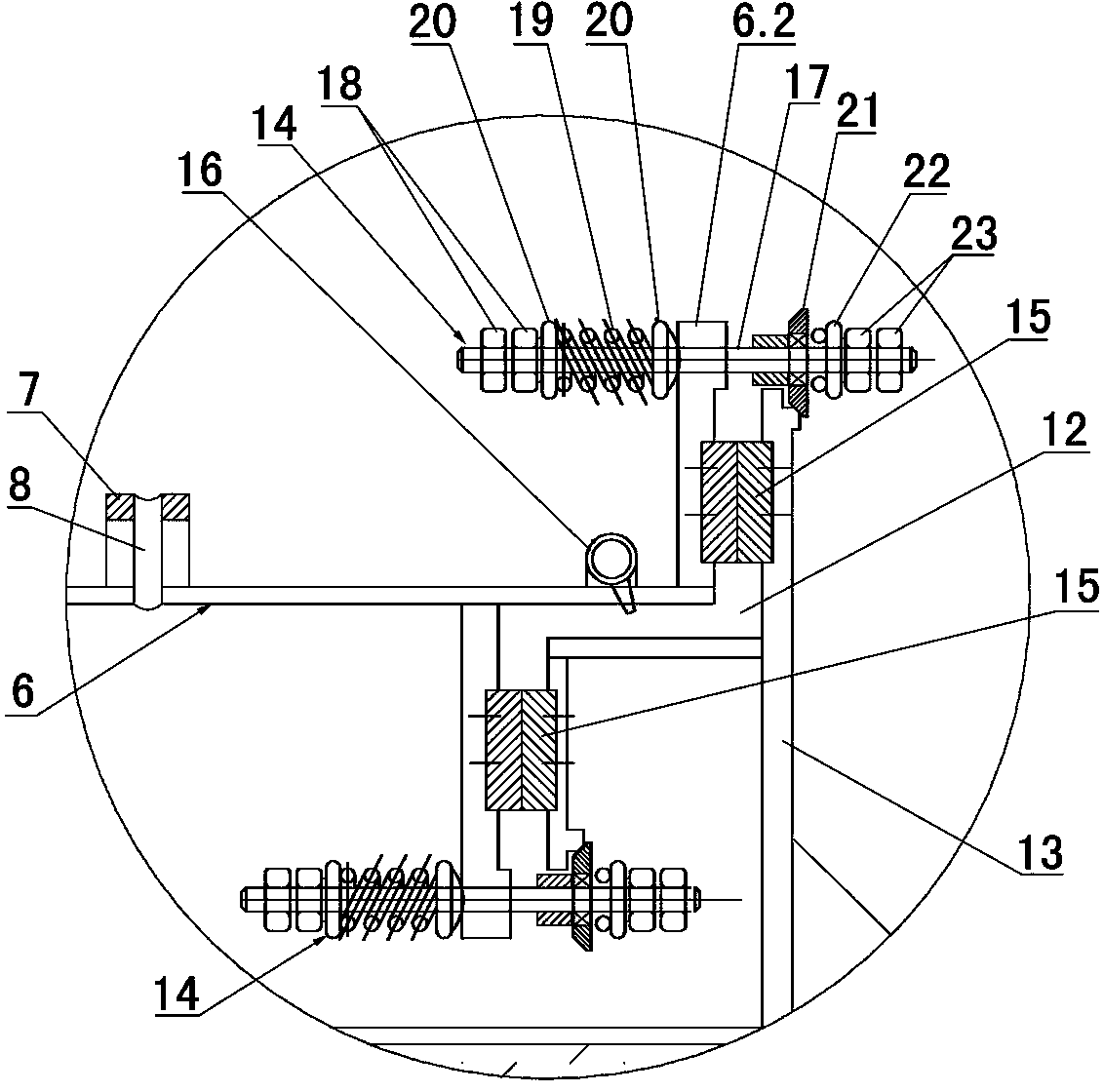

[0022] Examples see Figure 1-3 As shown, this sealing device with universal angle compensation tube is connected between the screw feeder 1 and the hollow journal 27 of the rotary retort furnace, including the universal angle compensation tube fixed on the screw feeder Flange 2, the universal angle compensation tube 3 that is sealingly connected with the universal angle compensation tube fixed flange 2 flange, the floating sealing tube 6 that is sealingly connected with the universal angle compensation tube 3 flange, and the rotary retort On the hollow journal 27 of the hollow journal 27, the hollow journal light flange 13 is connected and sealed with the floating sealing tube 6 and can rotate relative to the floating sealing tube 6.

[0023] The fixed flange 2 of the universal angle compensation tube is rigidly connected with the screw feeder 1, and the hollow journal flange 13 is rigidly connected with the hollow journal 27 of the rotary retort furnace and rotates according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com