Firecracker leading wire handpiece

A lead wire and firecracker technology, which is applied in the field of firecracker lead wire machine head, can solve the problems of affecting the guide accuracy of the lead wire entering the guide groove, easy loss of parts, and shaking of the wooden stick bracket, so as to achieve the effect of convenient maintenance, avoiding loss, and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

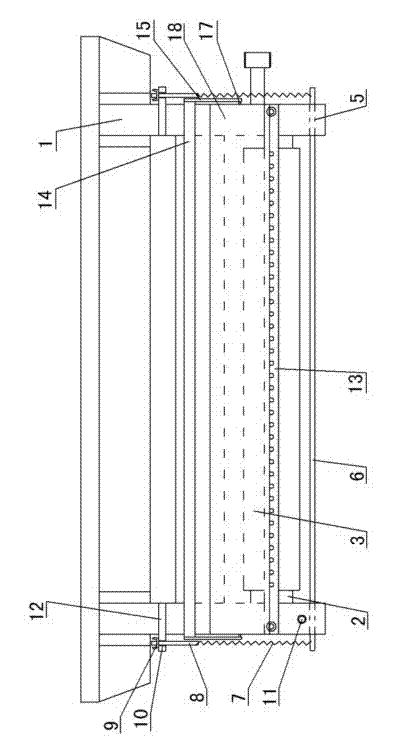

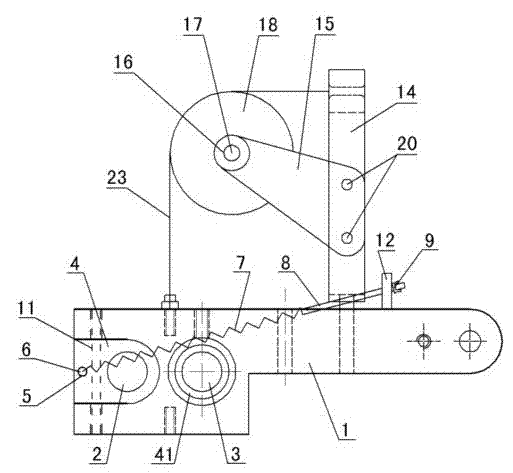

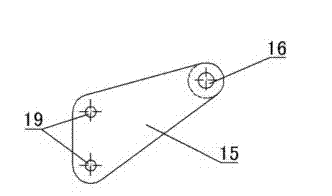

[0011] The invention relates to a firecracker lead wire machine head, such as figure 1 — Figure 4 As shown, it includes the front lead cot roller shaft 2, the rear lead cot roller shaft 3 and the lead guide groove 13. In the head rocker arm 1, a lead plate 14 is installed on the rocker arm 1, and wooden stick brackets 15 are respectively installed on both sides of the lead plate. The stick 18 is characterized in that the two bearing blocks 4 are formed with perforations 5, and the spring fixing rods 6 pass through the perforations, and springs 7 are respectively installed on the spring fixing rods 6 on the outside of the two bearing seats 4, and the other parts of the springs 7 One end is connected to the pull rod 8, the pull rod 8 is equipped with a buckle 9, and a clamp 12 is installed on the rear portion of the rocking arm 1, and the clamp 2 is formed with a draw-in groove 10, and the buckle 9 is matched with the draw-in groove 10. A rotor 11 is set in one of the block b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com