Nut of a planetary roller screw drive, and method for producing such a nut

A thread transmission, planetary roller technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

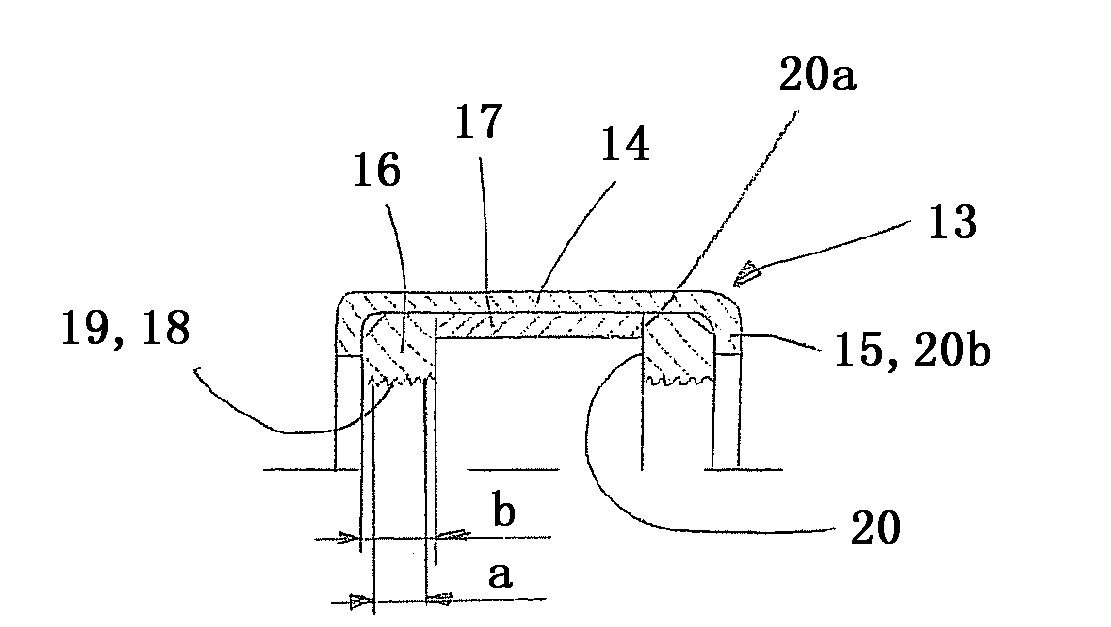

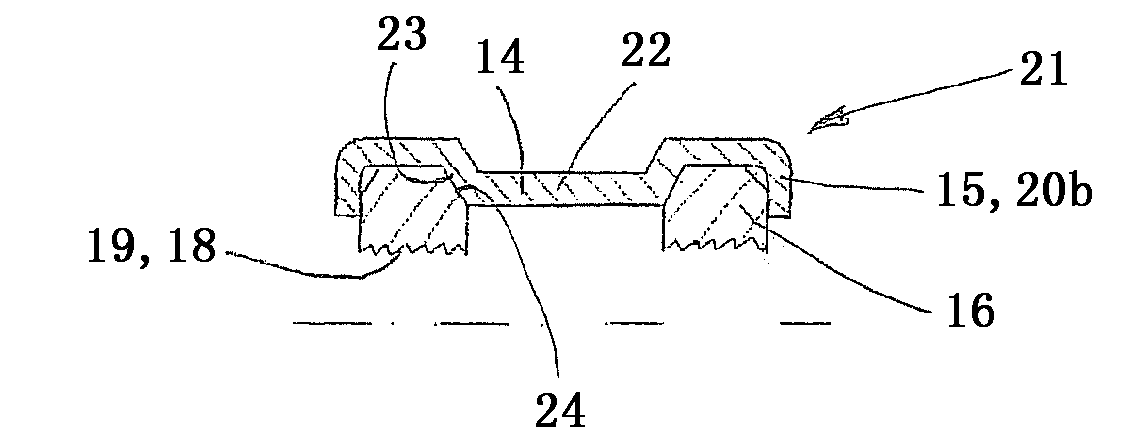

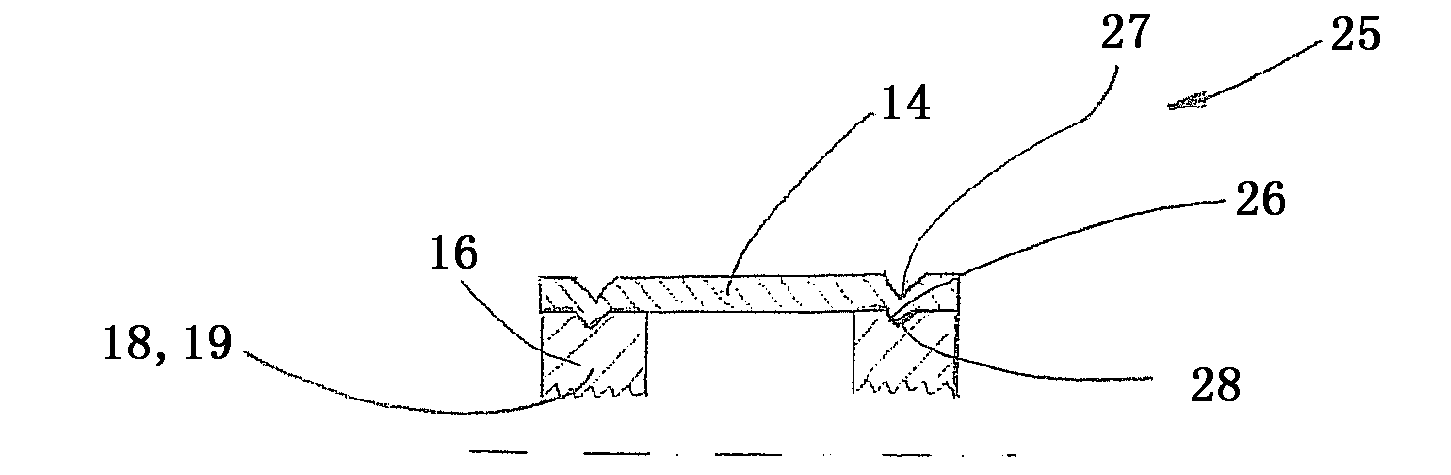

[0028] refer to Figure 4 First, the construction of a conventional planetary roller screw drive is described insofar as it is useful for understanding the present invention.

[0029] In this planetary roller screw transmission, the nut 1 is arranged on the threaded spindle 2 with the planetary elements 3 inserted in between. The lead screw 2 is provided with a helical thread 4 . The nut 1 is provided on its inner periphery with two groove profiles 5 which are each formed by a plurality of grooves 6 . The grooves 6 are annularly closed and are arranged parallel to one another in a plane lying transversely to the axis of the nut 1 .

[0030] The planet 3 has a central section 7 , and end sections 8 , which are radially descending relative to the central section 7 , and which are placed towards both axial sides of the central section 6 . The middle section 7 is provided with a grooved profile 9 on its outer circumference, which is formed by a plurality of grooves 10 . The gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com