Zip and zip teeth thereof

A zipper and sprocket technology, applied in the field of zippers and their sprockets, can solve the problems of limited lateral pulling force, water leakage of sprockets 101, lack of engaging structure, etc., so as to achieve the effect of improving meshing strength and increasing close effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

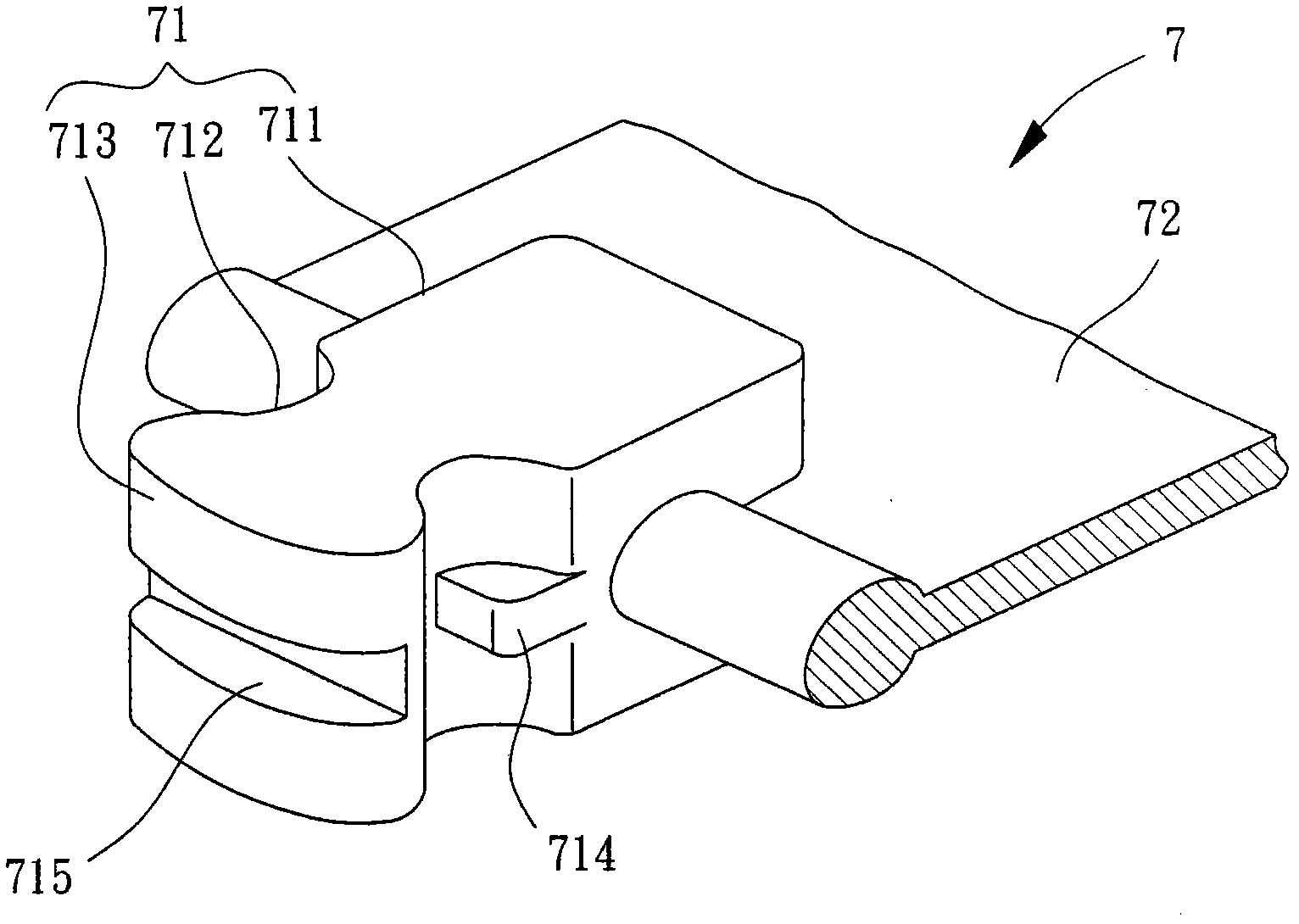

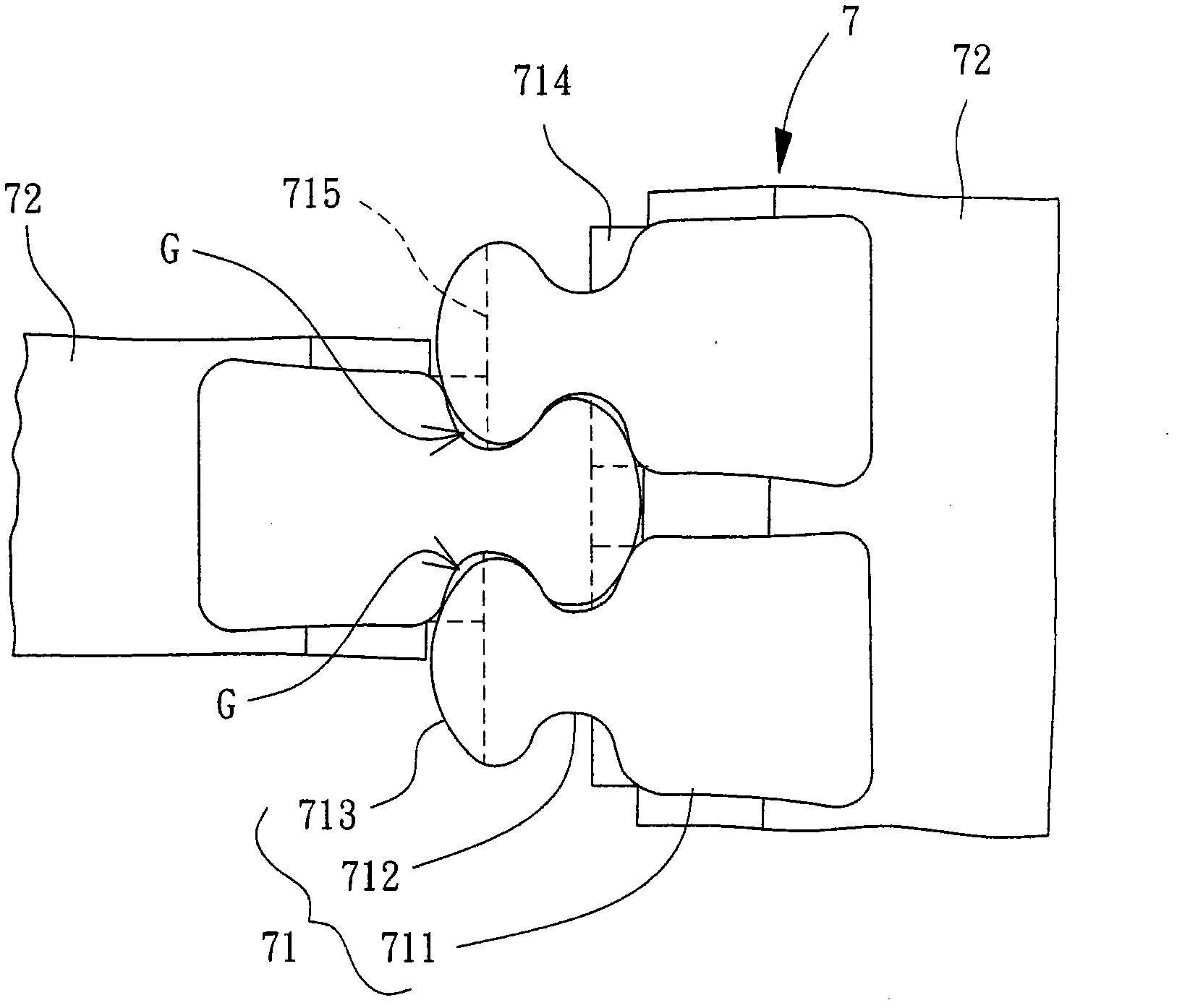

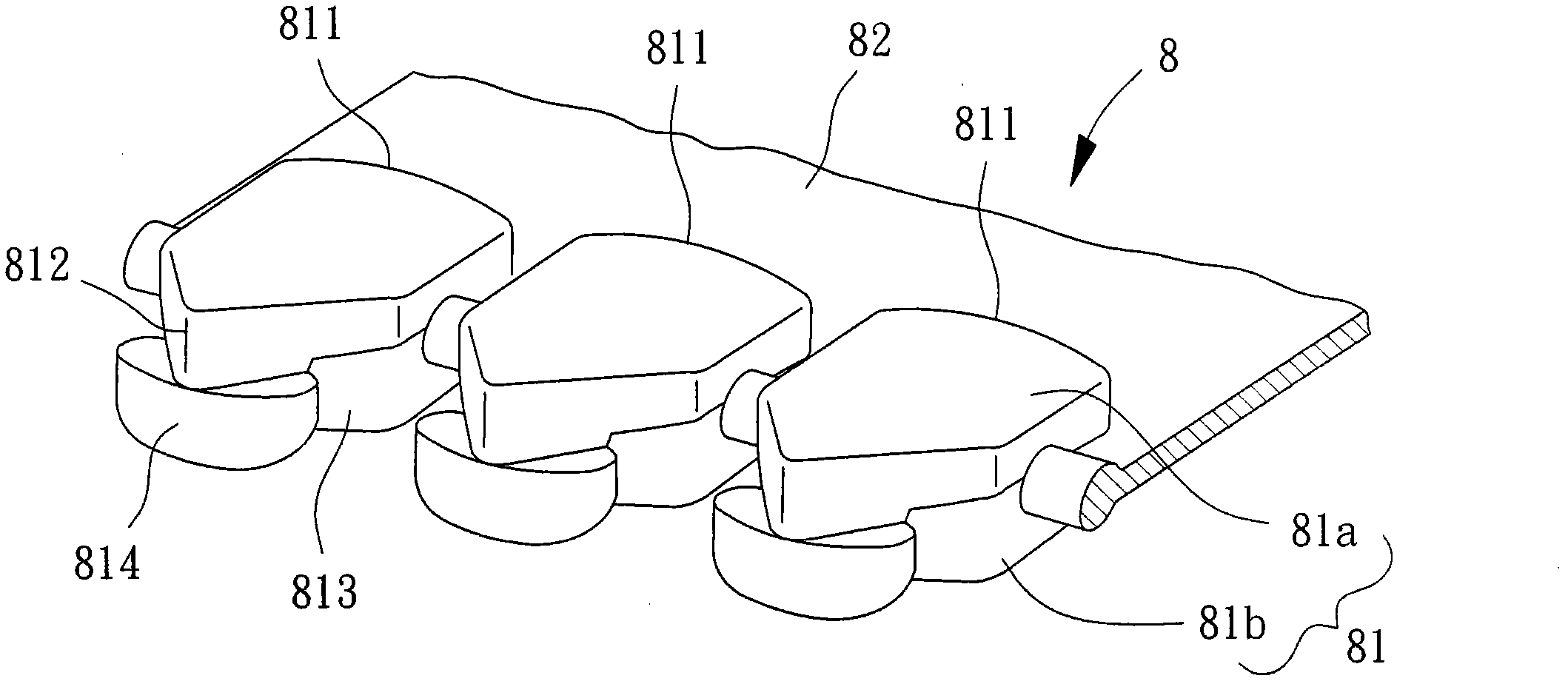

[0068] Please refer to Figure 8 to Figure 10 As shown, the zipper in the preferred embodiment of the present invention can be applied to various types of clothing such as jackets, trousers or raincoats, and can also be applied to structures such as clothing pockets, backpacks or waterproof bags. The zipper is composed of two chain cloths 1 and a plurality of chain teeth 2, the two chain cloths 1 are arranged oppositely, and the several chain teeth 2 are arranged in a staggered arrangement on the side edges of the two chain cloths 1 opposite to each other; Picture 9 As shown, it is a schematic diagram showing that a chain cloth 1 is provided with several chain teeth 2 side by side. In addition, each of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com