Narrow lifting chain traversing conveyor

A technology of lifting chains and conveyors, applied in the field of conveyors, can solve the problems of reducing the transmission power of roller conveyors and unfavorable material transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

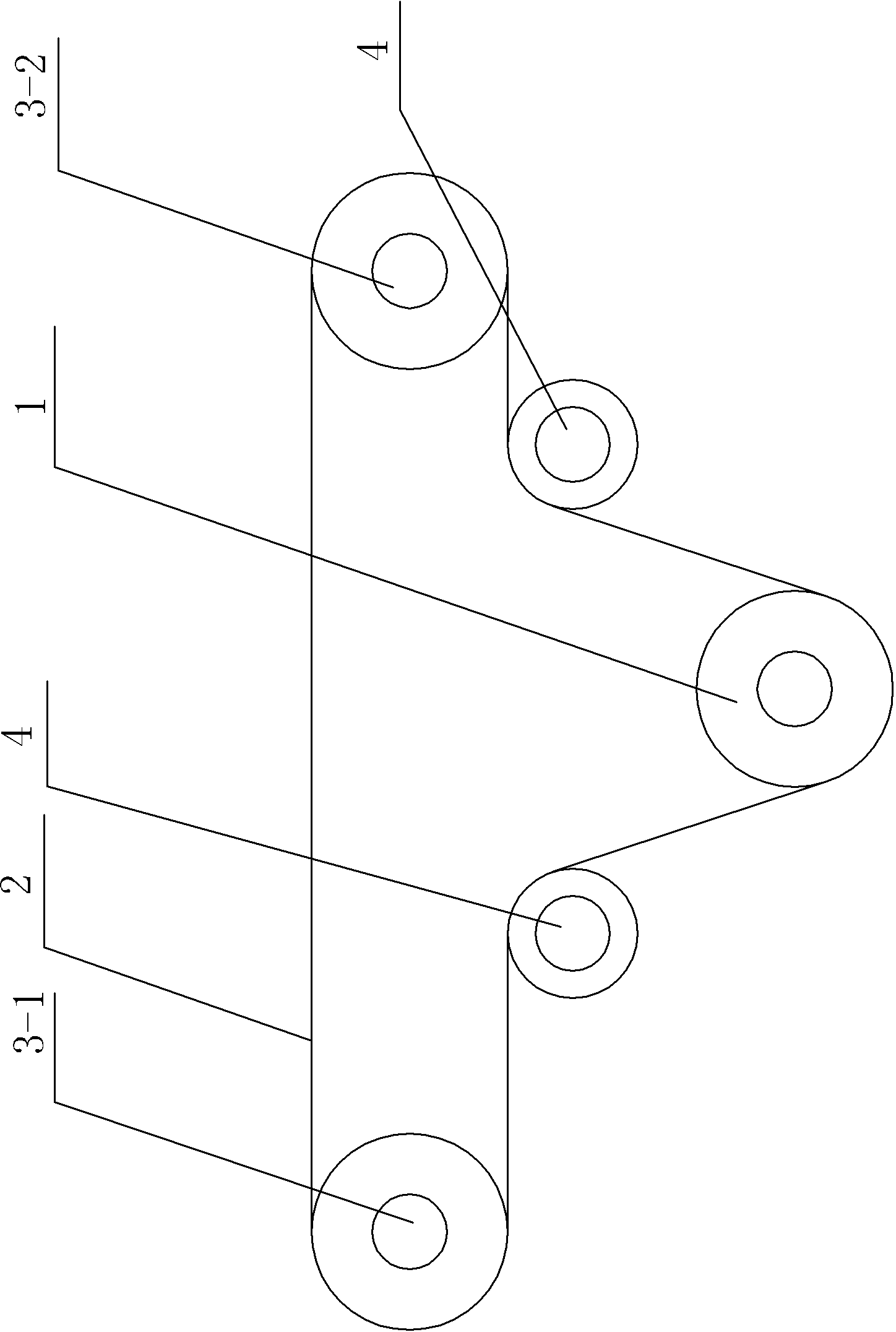

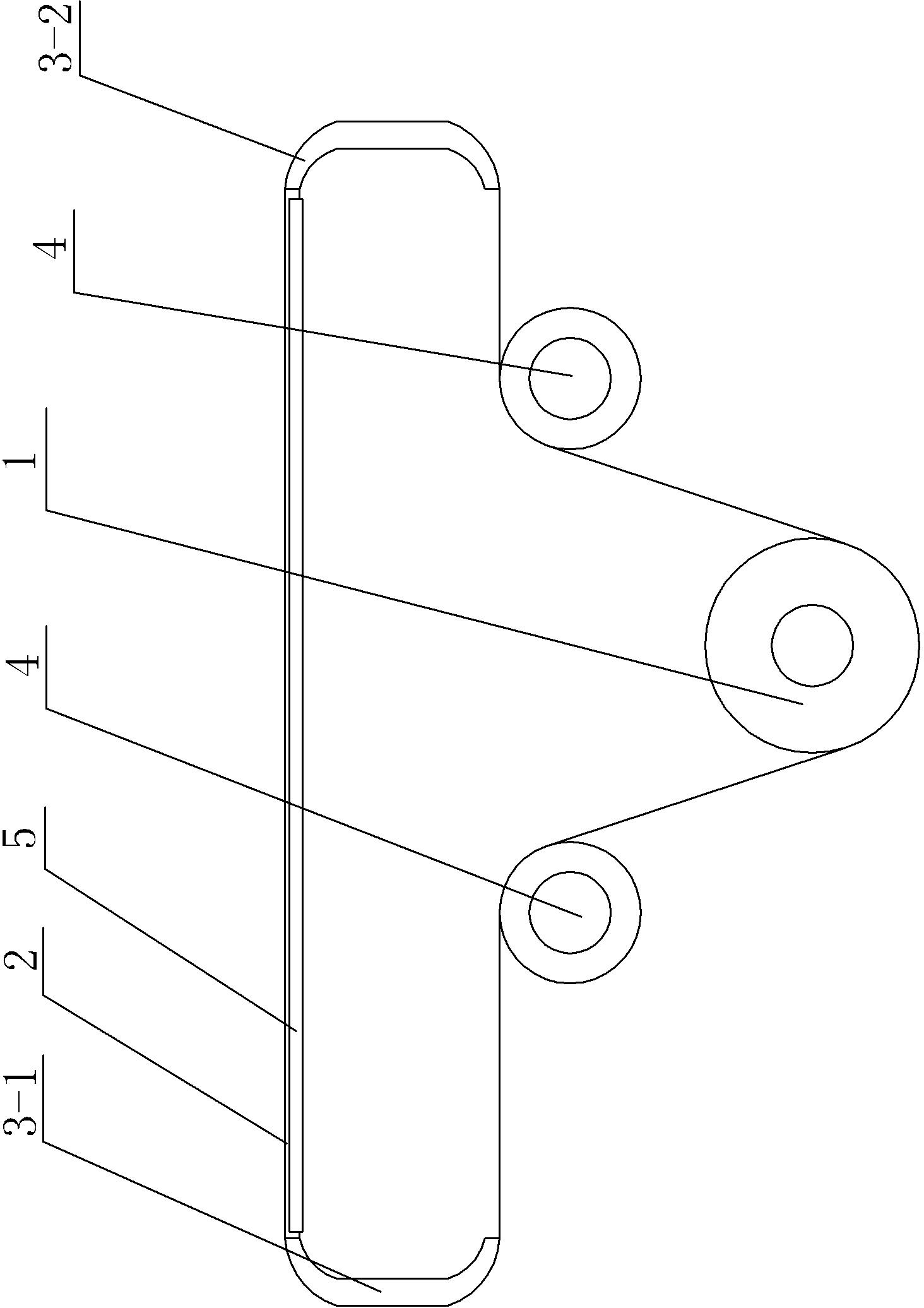

[0012] See figure 2 , a narrow lifting chain traverse conveyor, which includes a driving sprocket 1 and a chain 2, the two ends of the driving sprocket 1 are provided with nylon guide strips 3-1, 3-2, and the chain 2 passes through the driving sprocket 1 and the two ends Nylon guide strips 3-1, 3-2 form a closed loop. A supporting guide bar 5 corresponding to the chain 2 is arranged between the nylon guide bars 3-1, 3-2, and a supporting wheel 4 is respectively arranged between the drive sprocket 1 and the nylon guide bars 3-1, 3-2 at both ends, The supporting roller 4 supports the chain between the drive sprocket 1 and the nylon guide bar, so that the chain remains in tension.

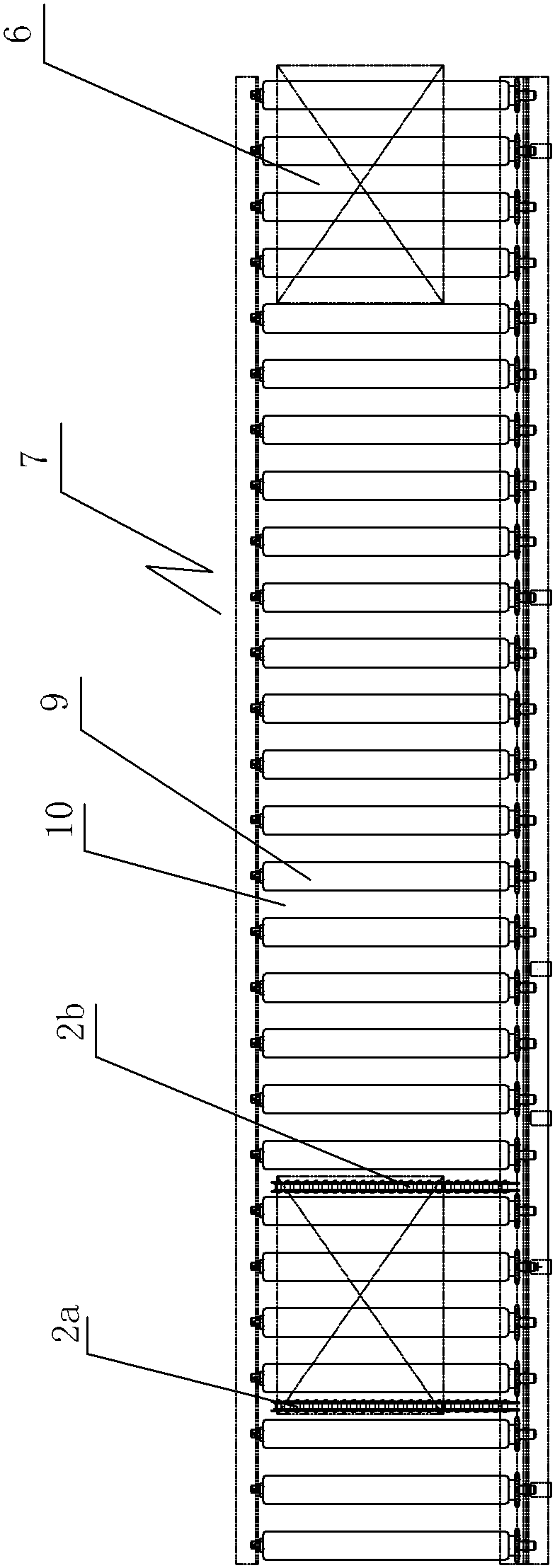

[0013] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 To illustrate the working principle of the narrow lifting chain traverse conveyor of the present invention:

[0014] When the material 6 is transported to the position of the narrow lift chain traverse conveyor throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com