Detection process for hole group of parallelogram web member

A technology of parallelogram and web bar, which is applied in the detection process field of parallelogram web bar hole groups, can solve the problems of different relative deviation values, inability to detect the relative size of the hole group, complex relative size of the wing plate and the web hole group, etc. Achieve high precision, solve measurement problems, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

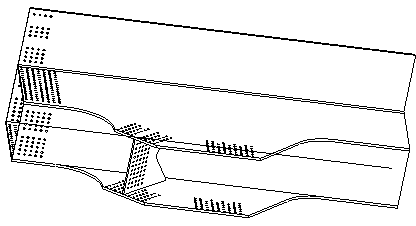

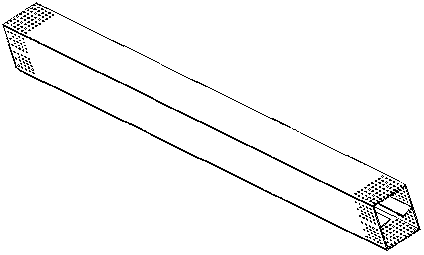

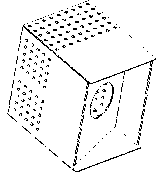

[0028] Such as Figure 1~Figure 11 shown, including steps,

[0029] 1) The standard splicing plate is installed on the standard beam head mold, and the standard splicing plate is not less than 10% of the number of bolt holes and 20% of the high-strength bolts; ( Figure 7 , Figure 8 )

[0030] 2) The web bar to be tested is placed on the platform and leveled; ( Figure 9 )

[0031] 3) Through the connection and positioning of the splice plate web and the standard beam head, the hole group on the web part should not be less than 10% of the number of bolt holes and 20% of the high-strength bolts; ( Figure 11 )

[0032] 4) The inspection contents include,

[0033] i. The rod detection should be carried out on the bench for level measurement, and the rod should be in a free state;

[0034] ii. After the standard beam head is installed in place, the flatness of the steel plate at the connection part of the high-strength bolts and the tightness of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com