Gas-shielded welding method for pearlite heat-resistant steel structural members

A technology for pearlitic heat-resistant steel and steel structural parts, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of carbon equivalent value reduction, welding strength reduction, etc., and achieve simple equipment , to avoid cracks, delay the effect of cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

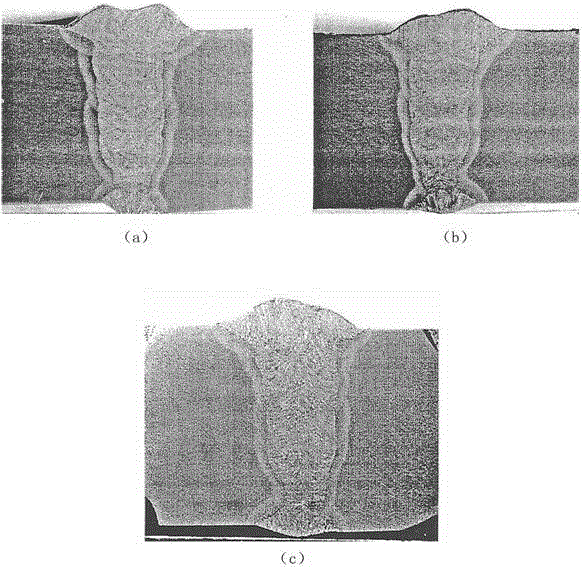

Embodiment Construction

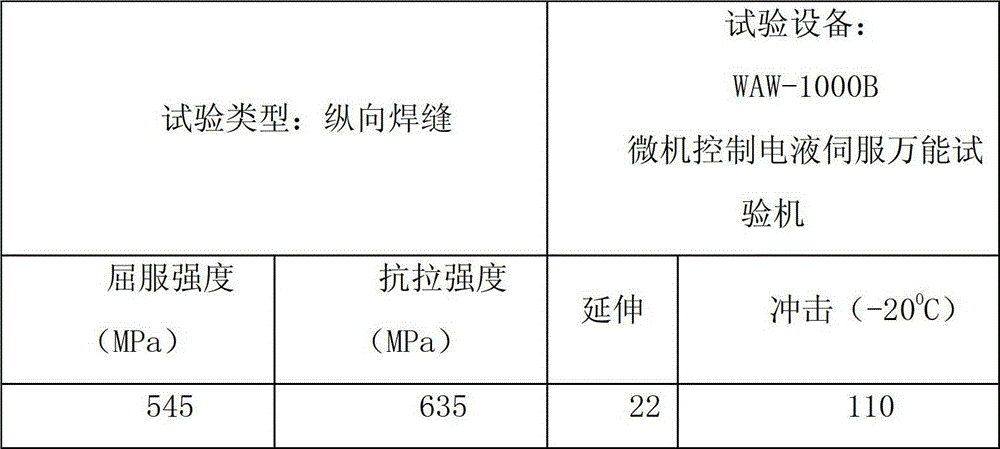

[0023] Adopt ASTMA3870 (American steel plate standard, similar to national standard 13CrMoA heat-resistant steel), thickness 100mm, mass fraction C≤0.17%, Mn0.4~0.65%, Si0.5~0.8%, Cr1.0~1.5%, Mo0.45 ~0.65%; total content of alloying elements ≥ 5%; matching welding material: 18CrMoA, diameter 1.2mm, mass fraction C 15~0.22%, Mn0.4~0.7%; Si0.15~0.35%; Cr0.8~1.10 %, Mo0.15~0.25%;

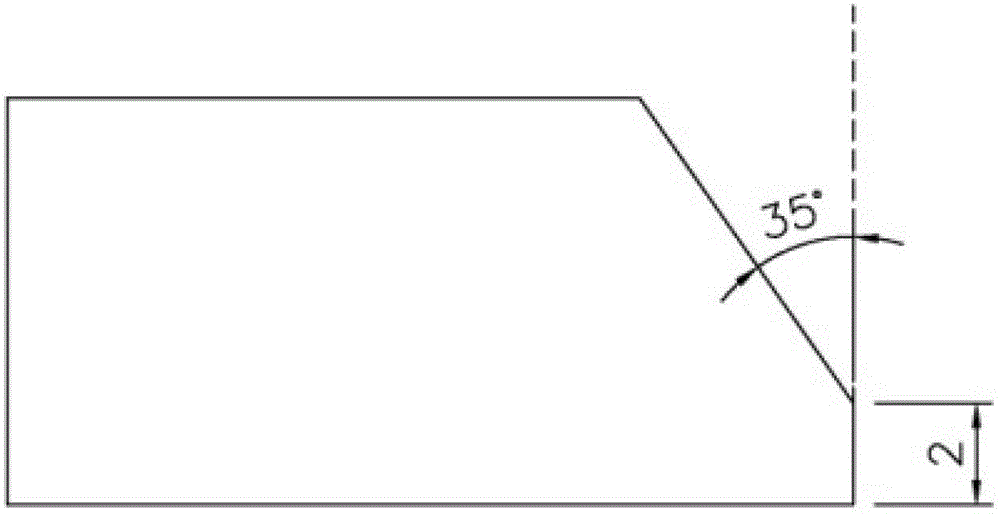

[0024] The protective groove adopts double-sided V-shaped groove, the angle of the groove is 35° on one side, and the blunt side is 2mm; no gap is left in the butt joint, and it is welded by fusion welding.

[0025] The equipment adopts DC welding power supply with surface tension transition characteristics, welding current 240~260A, welding voltage 24~28V, welding speed 30~35cm / min, welding line energy 13~16KJ / cm, M6×40×1.2 tapered external insulation Source contact tip; protective gas 80%Ar+20%CO 2 Argon-rich mixed gas substitute, gas flow rate 15L / min~20L / min; process measures: preheating temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap