Blanking jig structure for plastic sheet

A plastic sheet punching technology, applied in the field of plastic sheet punching fixture structure, can solve the problem of low cutting efficiency and achieve high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

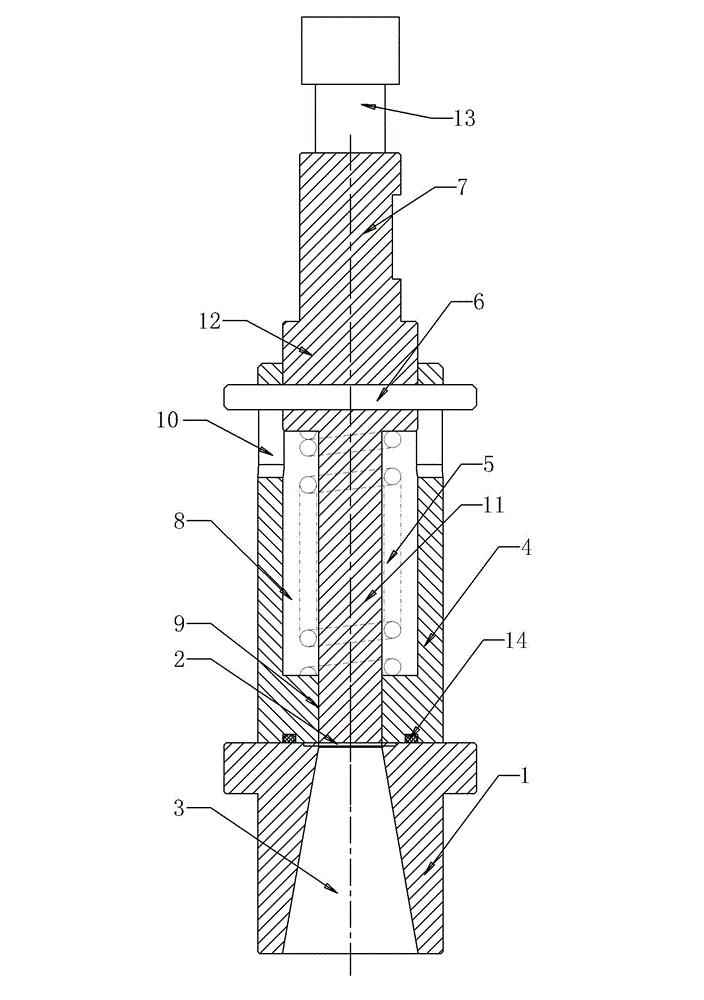

[0008] See figure 1 , which includes an upper mold and a bottom mold 1, a plastic sheet 2 is arranged in the middle of the punching position of the upper mold and the bottom mold 1, the bottom mold is provided with a lower mold cavity 3, and a plastic sheet 2 is arranged above the lower mold cavity 3, and the upper mold includes Sleeve 4, spring 5, pin 6, punch 7, the center of the sleeve 4 is provided with a punch installation hole, the punch installation hole is specifically divided into two sections: the upper section has a large aperture of 8, the lower section has a small aperture of 9, and the sleeve The upper ring surface of the barrel 4 is provided with a vertically arranged pin limit hole 10, the lower punch head 11 of the punch 7 passes through the punch installation hole and faces the plastic sheet 2 above the lower cavity 3, and the upper part of the punch 7 is supported The structure 12 is limited and connected in the pin limit hole 10 by the pin 6, the lower end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap