Fixing structure for rotating material chamber in carbon extruder

A fixed structure and extruder technology, which is applied in the field of fixed structure of the rotating material chamber of the carbon extruder, can solve the problems such as loose fixing and easy loosening of the rotating material chamber, and achieve the effect of solving the problem of loose fixing and preventing vibration or rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

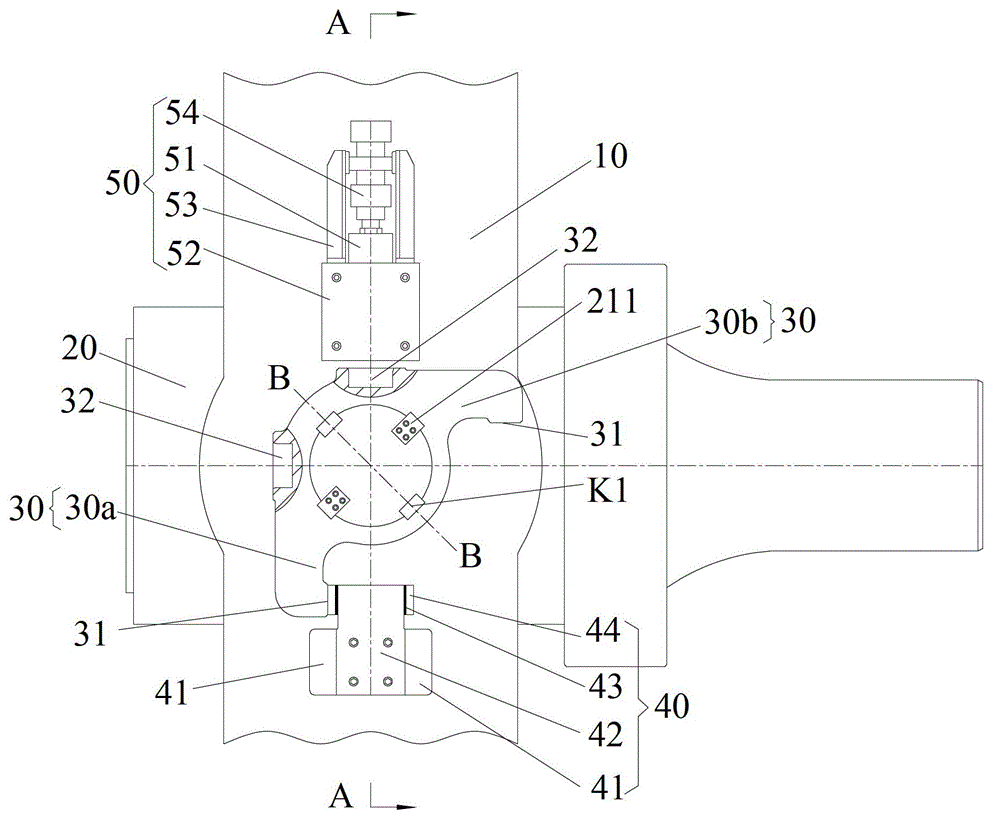

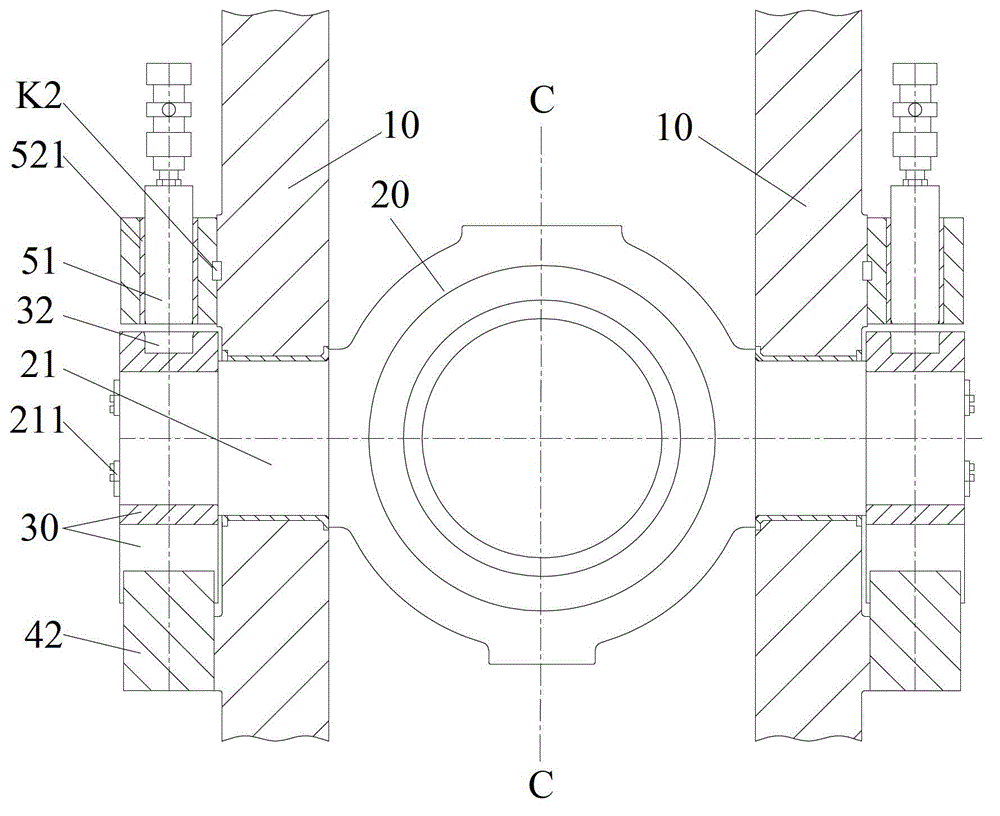

[0018] figure 1 It is a schematic diagram of an embodiment of the fixed structure of the rotary chamber of the carbon extruder of the present invention, figure 2 along figure 1 Sectional view of line A-A. Such as figure 1 and figure 2 As shown, in an embodiment of the present invention, the fixed structure of the rotating chamber of the carbon extruder is along the figure 2 The C-C line is left-right symmetrical, and includes two racks 10 , a rotating material chamber 20 , two rotating arms 30 , two positioning parts 40 and two latch parts 50 .

[0019] The rotating material chamber 20 is arranged between the two frames 10 and includes two symmetrically arranged trunnions 21 . Each of the two frames 10 has a shaft hole for the trunnion 21 to extend into, so that the rotating material chamber 20 can be rotatably arranged between the two frames 10 through the two trunnions 21, and the two trunnions 21 One end of each protrudes from the shaft holes of the two frames 10 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com