Skirting board bonding and mounting anti-loose fixing process

A baseboard, anti-loosening technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of foaming agent falling off and dispersing, reducing construction progress, unfavorable promotion and application, etc. The effect of firmly and widely promoting the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

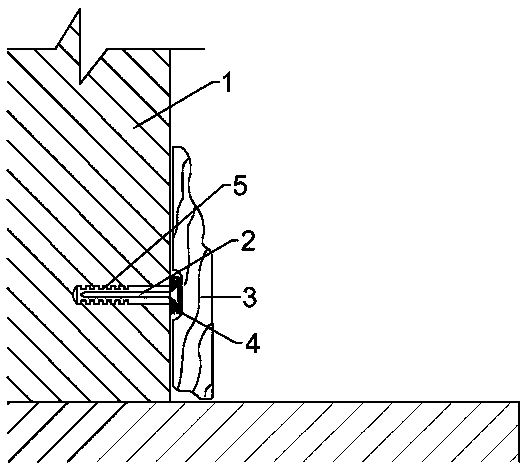

[0021] see figure 1 , in an embodiment of the present invention, a skirting line adhesive installation anti-loosening fixing process, comprising the following steps:

[0022] Step 1. Positioning: according to the height of the skirting, the line is horizontally stretched at the fixed point;

[0023] Step 2. Drilling: Use a drill bit to drill at a fixed point with a limited depth;

[0024] Step 3. Installation: Use the screw 2 to fix the nylon expansion tube 5 in the wall 1, and the anti-deformation groove on the back of the baseboard 3 is aligned with the screw 2;

[0025] Step 4, bonding: use AB glue 4 at the fixed point to bond the baseboard 3 and the cap of the screw 2 together.

Embodiment 2

[0027] see figure 1 , the fixed points are distributed in a cross, the diameter of the drill bit is 6mm, and the fixed points are distributed in a cross, which can effectively ensure accurate positioning during drilling.

[0028] Use a vacuum cleaner to remove dust when drilling, which can effectively prevent dust from spreading.

[0029] The caps of the screws 2 protrude from the wall by 3mm.

[0030] The beneficial effect of the present invention is that the skirting line 3 is firmly fixed and does not loosen, and the surface is not damaged, the construction quality is improved, and the utility model has wide popularization and application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com