Grasping mechanism

A technology of adjusting plates and fingers, applied in the directions of manipulators, conveyor objects, chucks, etc., can solve the problem of difficulty in sharing multiple production lines, and achieve the effect of reducing costs and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

[0019] A grabbing mechanism is characterized in that it comprises the following components:

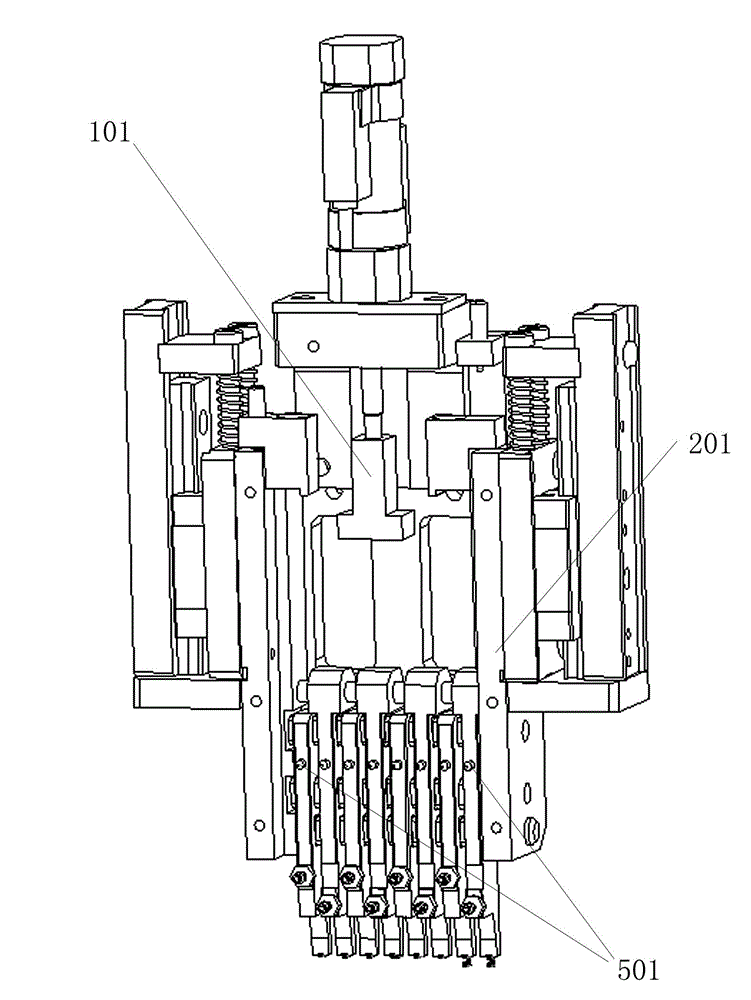

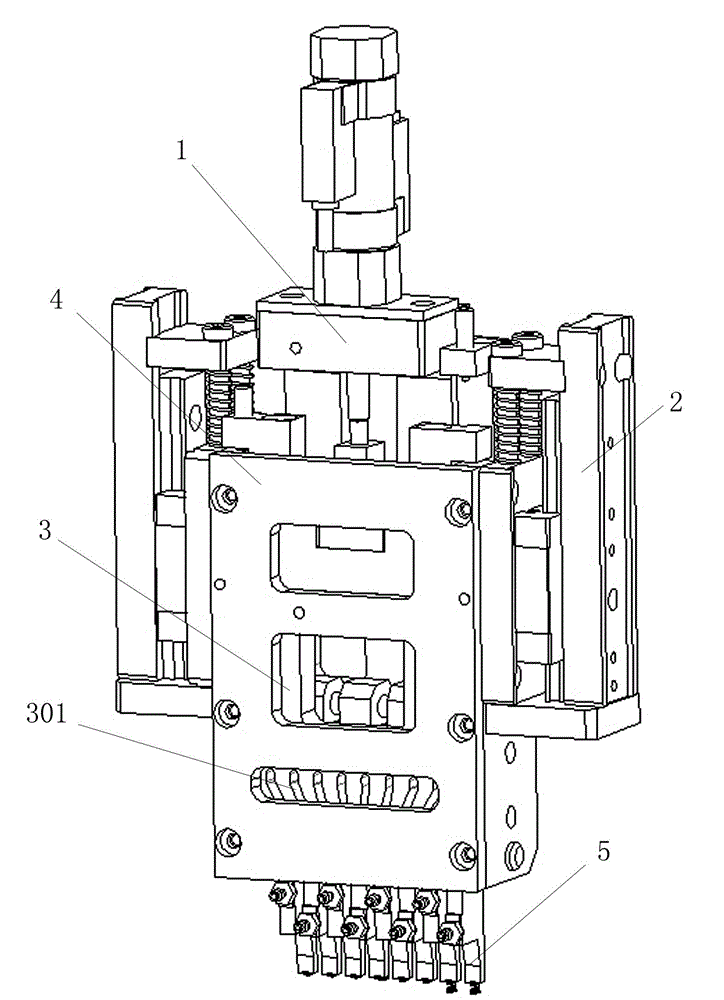

[0020] 1) Gripper jaw 5 for grabbing materials. The jaw 5 includes a plurality of fingers parallel to each other. There are through holes on the side of the fingers of the fingers, and the through holes between the fingers are aligned horizontally. The fingers, etc. Set side by side, the front of the finger bar of the clamp finger is provided with a positioning protrusion 501, and the positioning protrusions between the finger bars are located at the same level, such as figure 1 shown;

[0021] 2) The support 2 for fixing the jaws, the middle part of the support 2 is provided with an "H"-shaped bracket 201, the jaw 501 is located between the two vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com