Board feeding mechanism

A material feeding mechanism and plate technology, applied in the direction of object supply, thin material processing, object separation, etc., can solve the problems of high production cost of enterprises, low work efficiency of workers, inconvenient operation of workers, etc., to achieve simple maintenance work and improve work efficiency. , the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

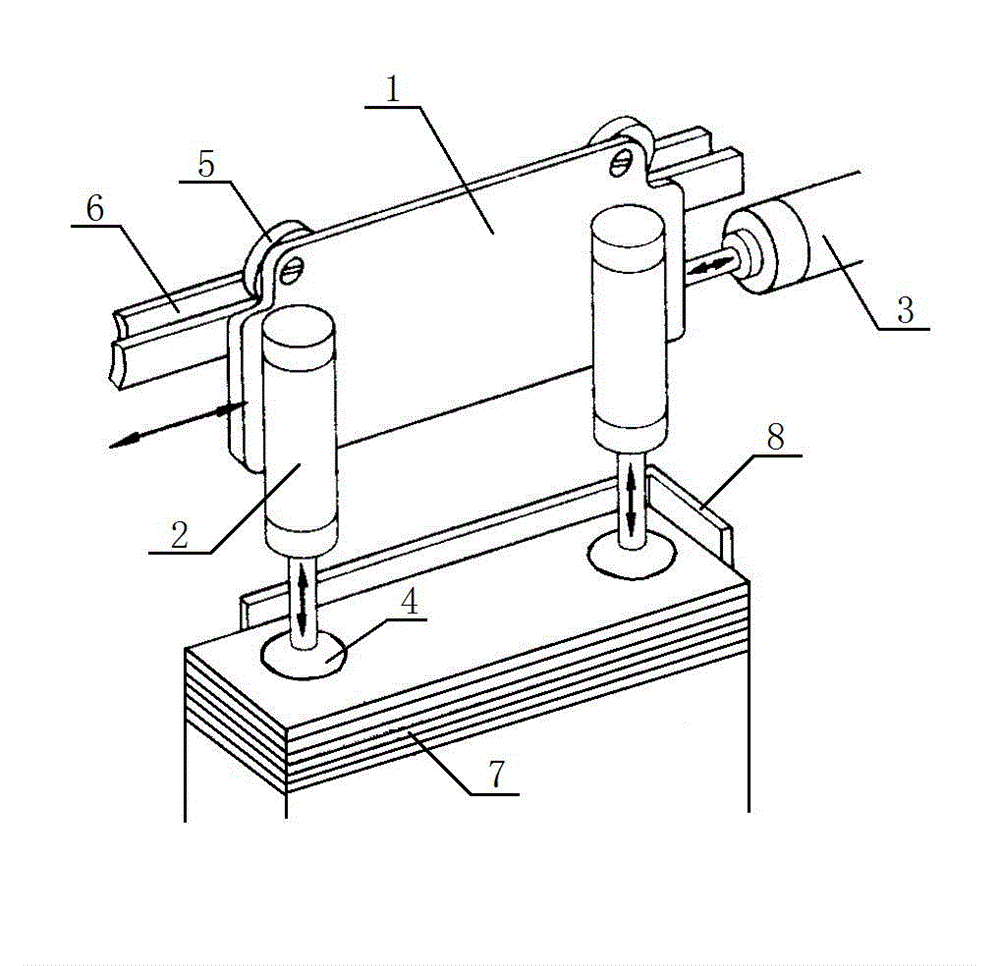

[0009] Such as figure 1 As shown, the present invention provides a plate feeding mechanism, comprising a cylinder mounting plate 1, the cylinder mounting plate 1 is provided with a lifting cylinder 2 in the longitudinal direction, a feeding cylinder 3 in the horizontal direction, a suction cup 4 is provided at the lower end of the lifting cylinder 2, and a suction cup 4 Facing the plate 7 , the cylinder mounting plate 1 is connected with a roller 5 , and the cylinder mounting plate 1 is slidingly connected with the slide rail 6 through the roller 5 ; the plate 7 is arranged in the bracket 8 .

[0010] In this embodiment, the lifting cylinder 2 can adjust the distance between the suction cup 4 and the plate 7, and the feed cylinder 3 can adjust the position of the cylinder mounting plate 1, thereby adjusting the relative position between the suction cup 4 and the plate 7, which is the plate 7 The absorption provides conditions. In fact, the adjustment of the feed cylinder 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com