Sealing gasket for motor vehicle

A technology for sealing gaskets and motor vehicles, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of easy rust, poor adaptive sealing performance, rough processing surface, etc., to achieve long service life and improve service life , the effect of reducing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

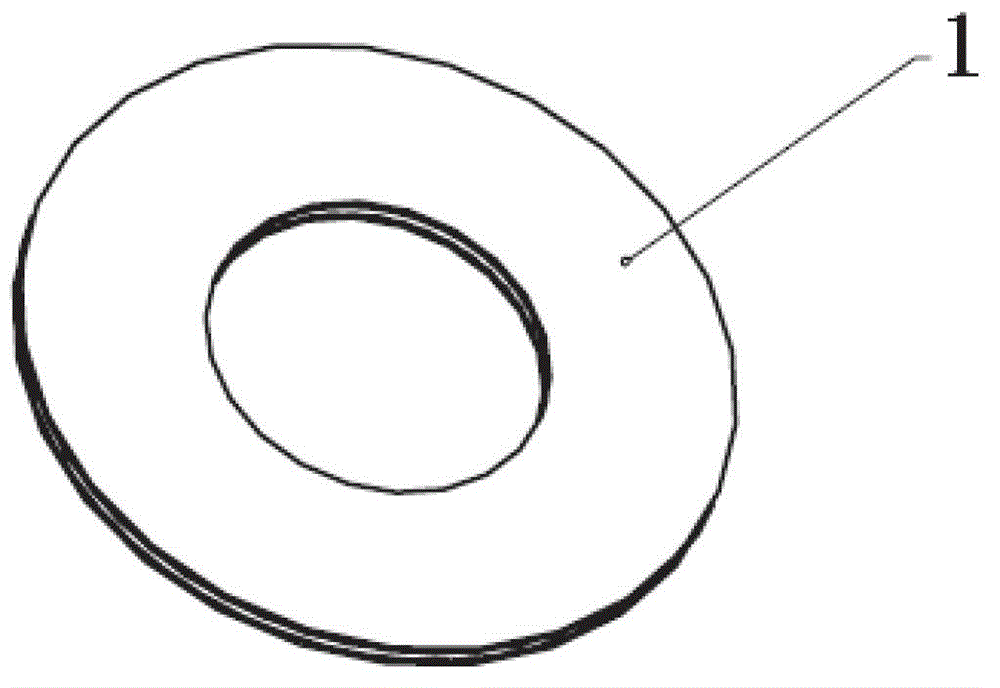

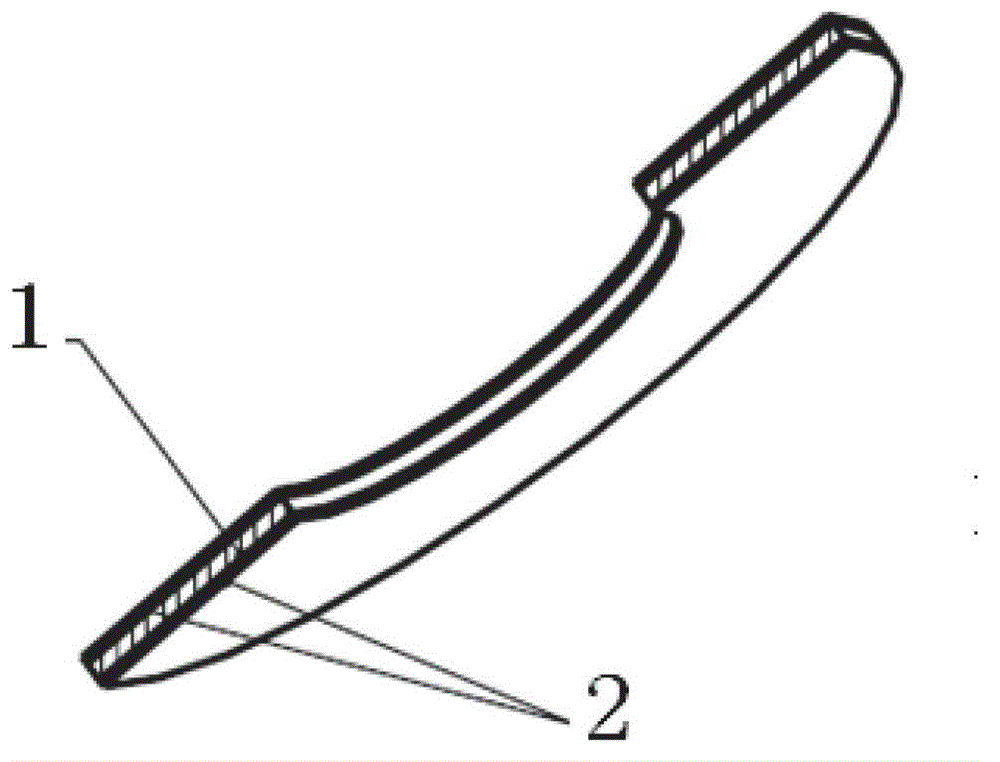

[0025] Such as Figure 1-2 As shown, a sealing gasket for a motor vehicle includes a metal gasket 1 with a circular hole in the middle of the metal gasket 1 and a coating layer 2 on the outer surface of the metal gasket 1 . The coating layer 2 is a rubber coating layer 2, and the rubber coating layer 2 is a rubber composite material wrapped with tetrafluoroethylene. On the rubber coating layer 2 on the front and back of the metal gasket 1, the thickness of the rubber layer gradually changes from thin to thick in the direction from the middle to the periphery. The material of the metal gasket 1 is iron, copper or aluminum. The metal gasket 1 is also provided with several small holes, and the front and back coating layers 2 on the metal gasket 1 are connected together through the small holes. The overall front view of the metal gasket 1 is circular; the overall side view of the metal gasket 1 is arched. The overall side sectional view of the metal gasket 1 is an arc, with low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com