Backlight module and liquid crystal display device

A technology of a liquid crystal display device and a backlight module, applied in lighting devices, fixed lighting devices, cooling/heating devices of lighting devices, etc., capable of solving problems such as uneven brightness of a liquid crystal panel 110, and achieving the effect of reducing uneven brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following description will be made in conjunction with the accompanying drawings and specific implementation manners.

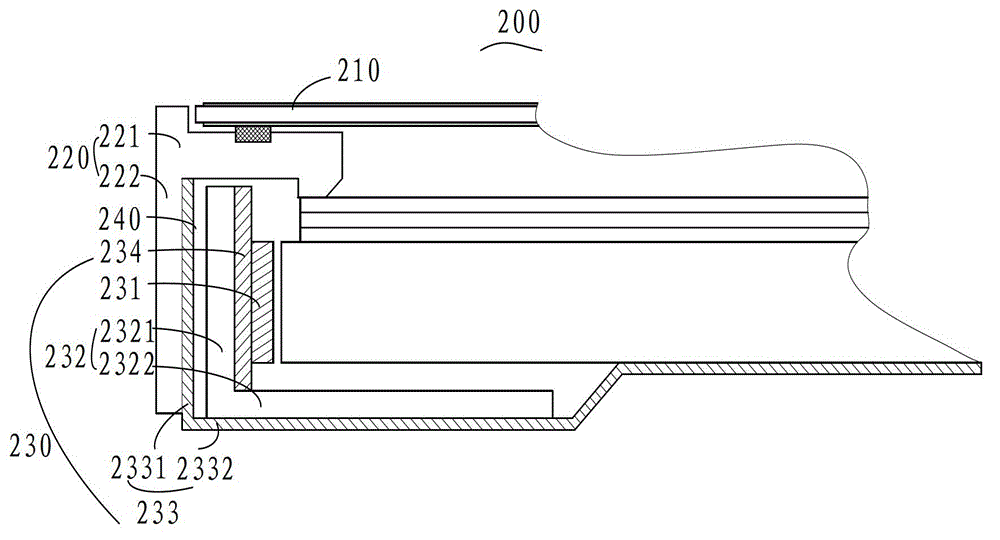

[0022] see figure 2 , figure 2 It is a partial structural schematic diagram of an embodiment of the liquid crystal display device of the present invention. In this embodiment, the liquid crystal display device 200 includes: a liquid crystal panel 210 , a middle frame 220 , a backlight module 230 and a heat blocking mechanism 240 .

[0023] The middle frame 220 includes a rectangular frame body 221 with a window in the middle and a first side plate 222 extending downward from the outside of the rectangular frame body 221 . The backlight module 230 includes a light source 231 , a heat conductor 232 , a backplane 233 and an MCPCB 234 . The back plate 233 includes a first bottom plate 2332 and a second side plate 2331 bent upward from the outer side of the first bottom plate 2332 . The heat conductor 232 includes a second bottom plate 2322 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com