Detection device for variable section intake manifold control valve plate

A technology for intake manifolds and detection devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc. It can solve the problem of the deviation of the center position of the control valve, the inability to smoothly assemble the control valve, and the bending of the drive shaft of the valve, etc. problems, to achieve the effect of ensuring accuracy, ensuring assembly quality, and avoiding force bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

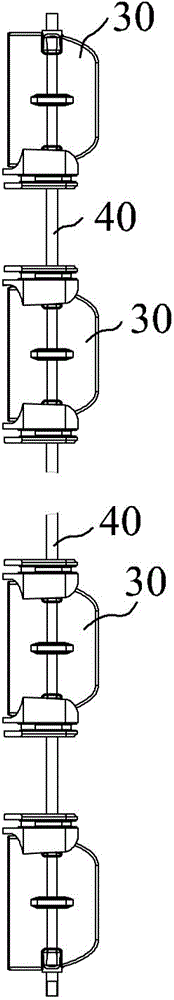

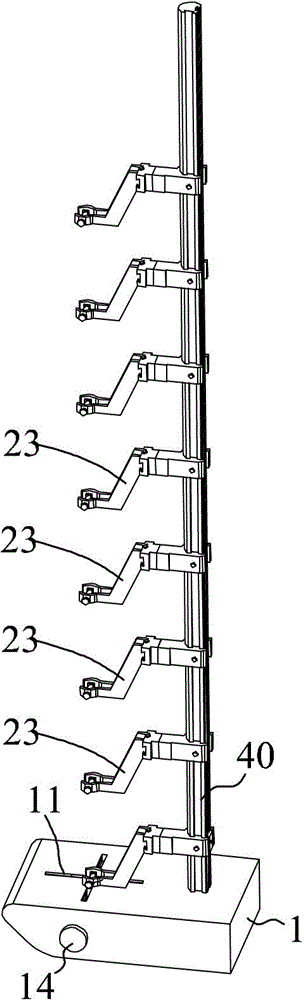

[0021] Such as figure 1 Shown is a schematic structural view of the control valve plate 30 to be tested and the valve drive shaft 40, the center position size of each control valve plate 30 is crucial for assembly, figure 2 The detection device of the variable cross-section intake manifold control valve plate in this embodiment is used for its detection. The detection device includes a base 1 on which a fixing device for clamping an end of the drive shaft 40 of the valve plate and a measuring device for measuring and controlling the valve plate 30 are arranged.

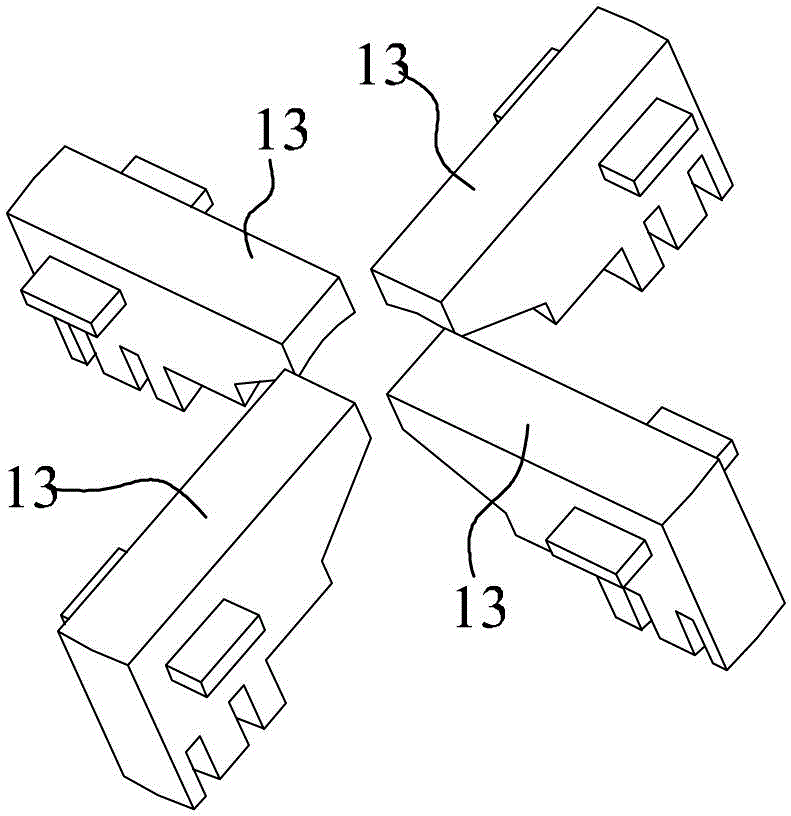

[0022] Such as image 3 and Figure 4 As shown, the fixing device includes a cross-through groove 11 arranged on the base 1, a spiral groove plate 12 arranged below the cross-through groove 11 for rotation, four movable parts slidably arranged in the cross-through groove 11 and engaged with the spiral groove plate 12 The clamping block 13 and the tooth shape meshing with the spiral grooved disk 12 drive the manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com