Ventilating waterproof LED display module box

A technology for display modules and cabinets, applied in cooling/ventilation/heating transformation, instruments, identification devices, etc., can solve problems such as unsatisfactory waterproof and heat dissipation effects, complex waterproof and heat dissipation structures, etc., and achieve good waterproof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

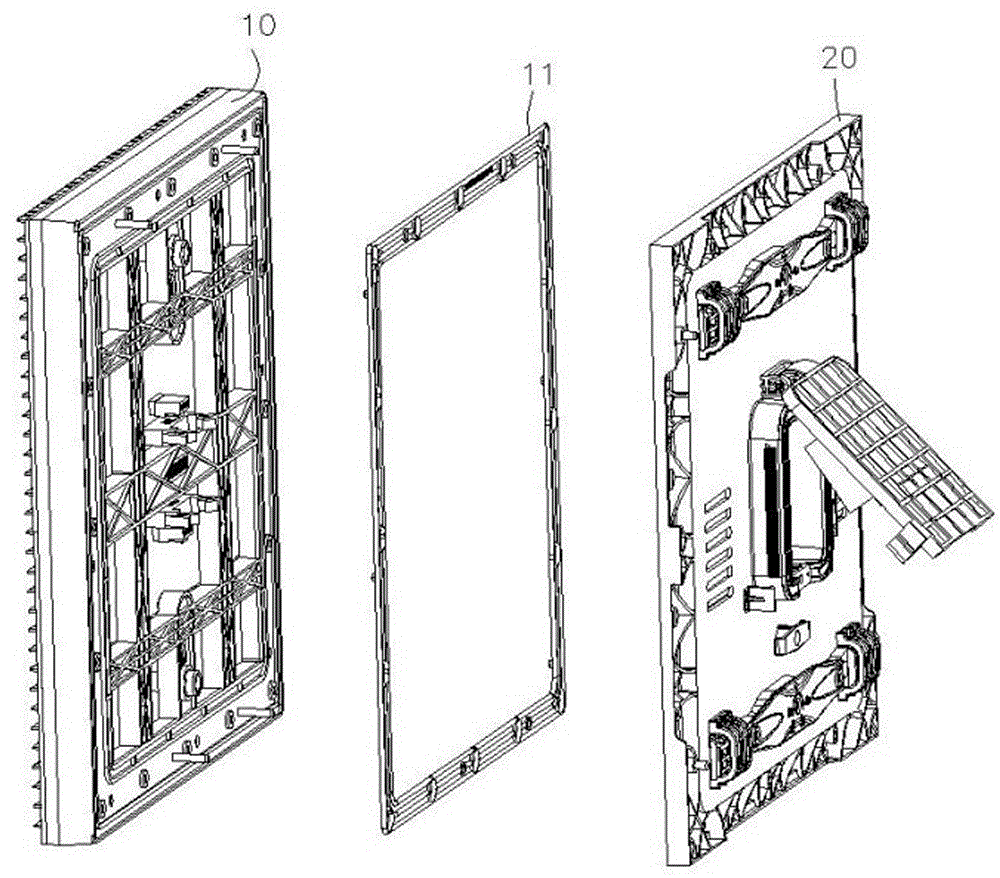

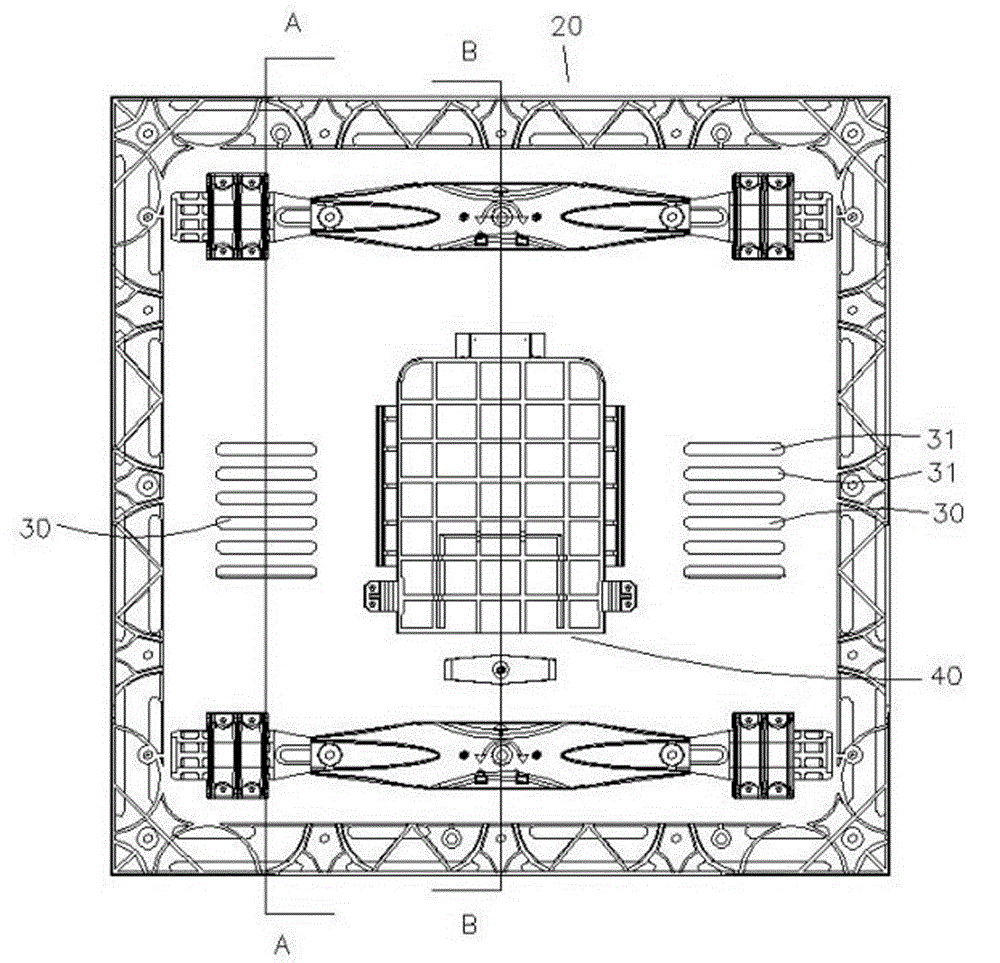

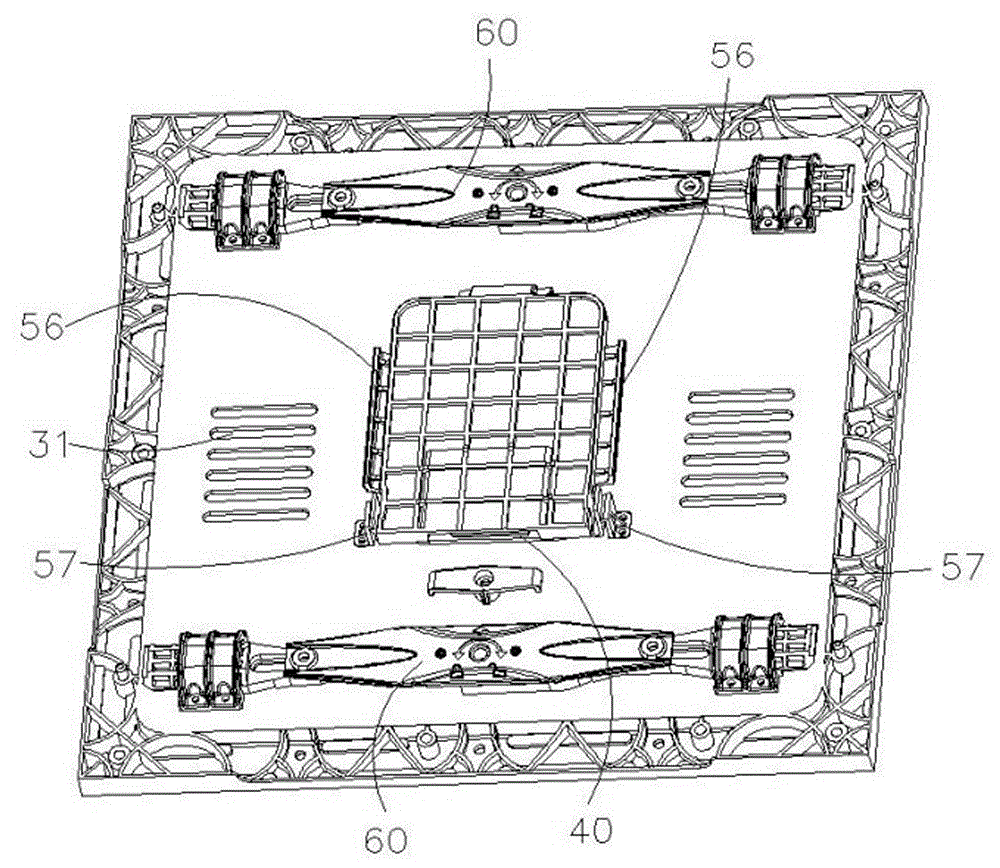

[0023] Such as Figures 1 to 7 As shown, a ventilated and waterproof LED display module box includes a bottom case 10 and a waterproof cover 20 .

[0024] The waterproof cover 20 is disposed behind the bottom case 10 .

[0025] During specific implementation, components such as LED lamp boards, PCB circuit boards, and face shields are connected in front of the bottom case 10, and various electronic components are arranged between the waterproof cover plate 20 and the bottom case 10. The relationship makes the above-mentioned various components connected together to form a whole LED display module.

[0026] During specific implementation, a box body waterproof rubber ring 11 is also arranged between the bottom case 10 and the waterproof cover plate 20, and the waterproof cover plate 20 is covered behind the bottom case 10 through the box body waterproof rubber ring 11. When the overall structure can be waterproof.

[0027] An inner cavity is formed around the waterproof cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com