Array substrate, manufacturing method thereof, and display device

An array substrate and manufacturing method technology, applied in the field of liquid crystal display, can solve problems such as electrostatic breakdown and easy accumulation of charges, and achieve the effect of increasing common electrode resistance and reducing electrostatic breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

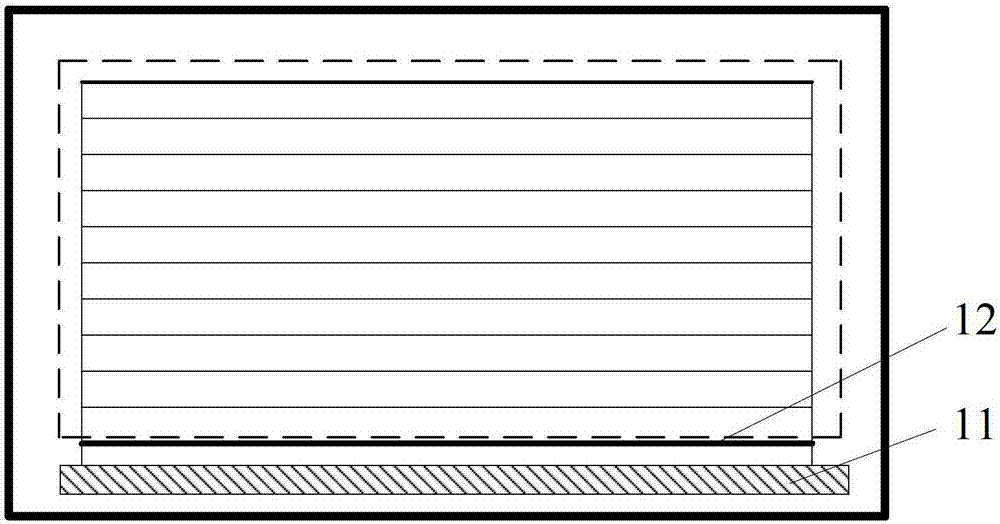

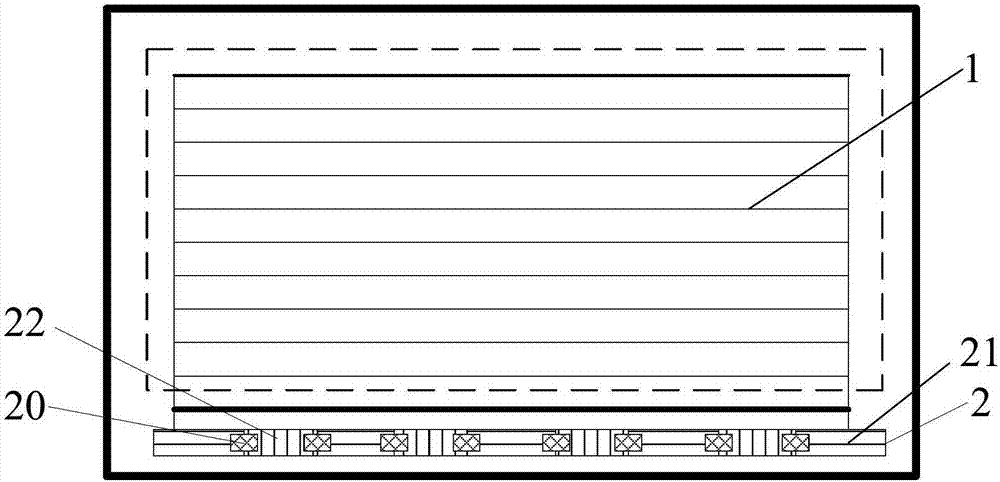

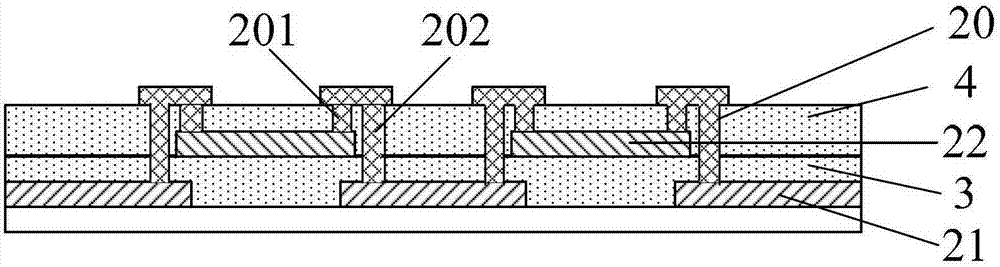

[0036] This embodiment provides an array substrate, such as figure 2 and image 3 As shown, it includes a common electrode bus 2 and a plurality of parallel common electrode lines 1, wherein the common electrode bus 2 is located outside the effective display area, the common electrode line 1 is located inside the effective display area, and the plurality of parallel common electrode lines 1 connected together in parallel. The common electrode bus 2 in this embodiment includes a plurality of spaced gate metal segments 21 and a plurality of spaced source-drain metal segments 22, and the source-drain metal segments 22 correspond to the gaps between the gate metal segments 21. The vacant position of the gate metal segment 21 is separated from the source-drain metal segment 22 by the first insulating layer 3. As an embodiment of the present invention, the first insulating layer 3 may be a gate Insulation. Preferably, the gate metal segment 21 and the source-drain metal segment ...

Embodiment 2

[0056] This embodiment provides an array substrate, such as figure 2 As shown, it includes a common electrode bus 2 and a plurality of parallel common electrode lines 1, wherein the common electrode bus 2 is located outside the effective display area, the common electrode line 1 is located inside the effective display area, and the plurality of parallel common electrode lines 1 connected together in parallel. The common electrode bus 2 in this embodiment includes a plurality of spaced gate metal segments 21 and a plurality of spaced source-drain metal segments 22, and the source-drain metal segments 22 correspond to the gaps between the gate metal segments 21. The vacant position of the gate metal segment 21 is separated from the source-drain metal segment 22 by the first insulating layer 3. As an embodiment of the present invention, the first insulating layer 3 may be a gate insulating layer. Preferably, the gate metal segment 21 and the source-drain metal segment 22 have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com