Breathing type hollow BIPV (building integrated photovoltaics) assembly

A photovoltaic module, breathable technology, applied in the field of breathable hollow BIPV photovoltaic modules, can solve the problems of gas expansion in the hollow layer, rupture of hollow photovoltaic modules, affecting the power generation efficiency of photovoltaic cells, etc., achieve high heat insulation effect, and avoid glass breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

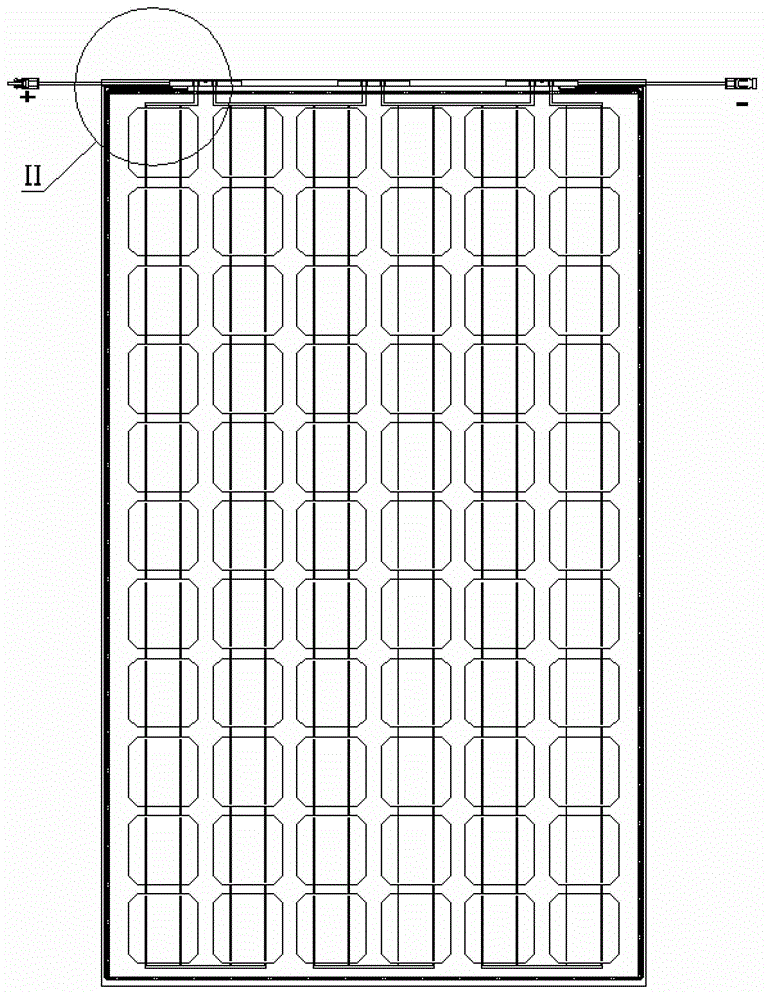

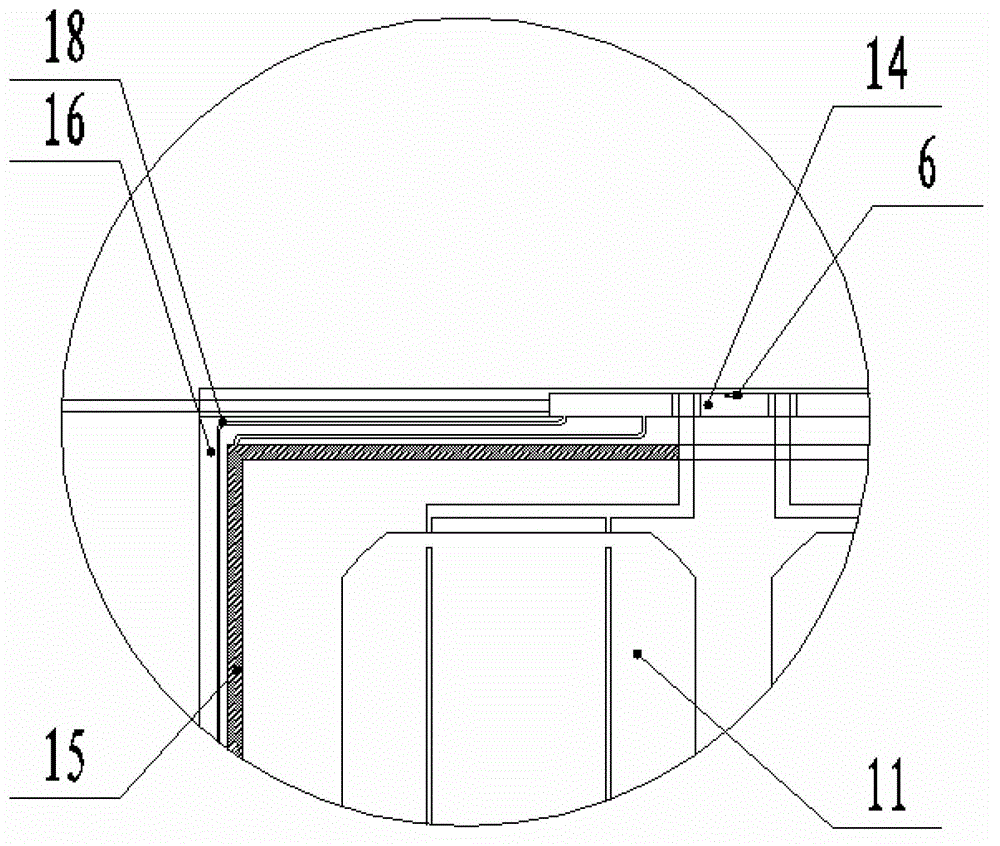

[0027] Such as figure 1 , 2 , 3, 4, 5, and 6, the present invention is a breathing type hollow BIPV photovoltaic module, including front glass 10, solar battery sheet group 11, substrate glass 12, hollow layer 17 and back glass 13 stacked in sequence, wherein A spacer 15 is installed between the substrate glass 12 and the back glass 13 so as to form the hollow layer 17, a sealant 16 is used for air sealing between the substrate glass 12 and the back glass 13 outside the spacer 15, and the front glass 10 A junction box 14 is installed between the back glass 13 and electrically connected to the junction terminals of the aforementioned solar cell array 11 .

[0028] The front glass 10 is made of low-iron ultra-clear tempered glass, and the substrate glass 12 is made of low-emissivity glass that only reflects infrared light with a wavelength above 1100nm. The low-emission glass is formed by covering the tempered glass with an infrared reflective film. In addition, a desiccant is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap