Multi-pole-set battery and manufacture method thereof

A battery and electrode assembly technology, applied in the field of multi-electrode secondary battery and its manufacturing, can solve the problems of low manufacturing process efficiency and potential safety hazards, and achieve the goal of improving battery performance and consistency, reducing potential safety hazards, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Exemplary embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

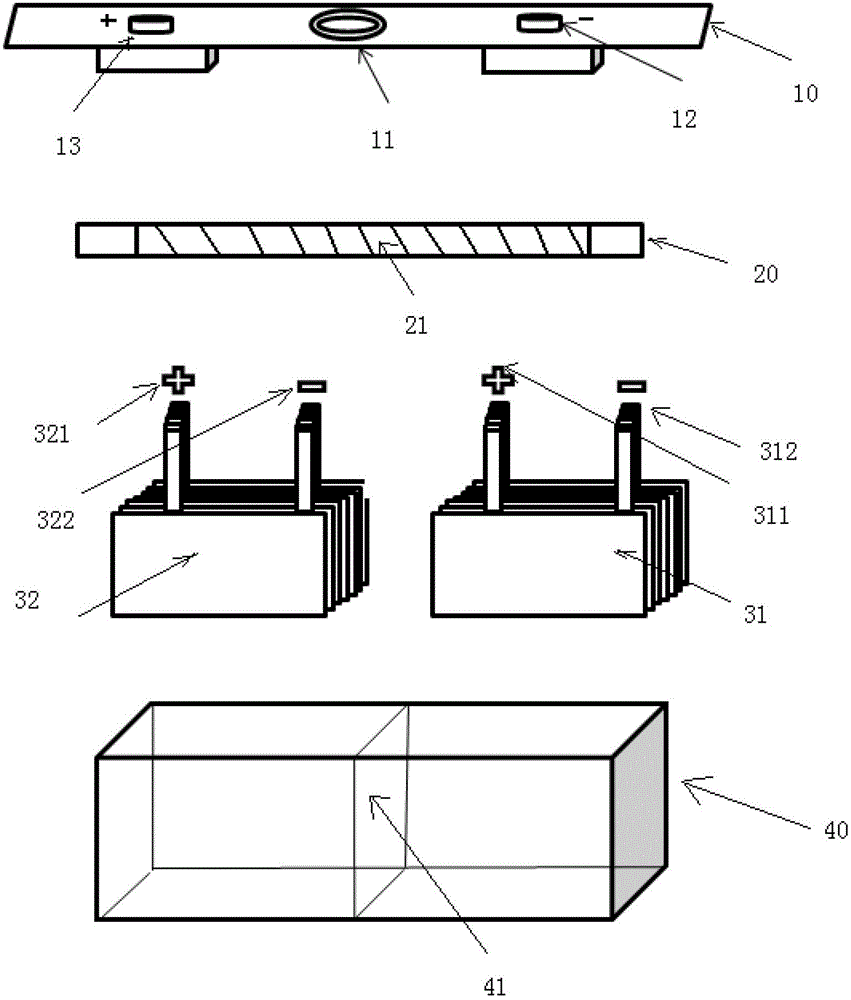

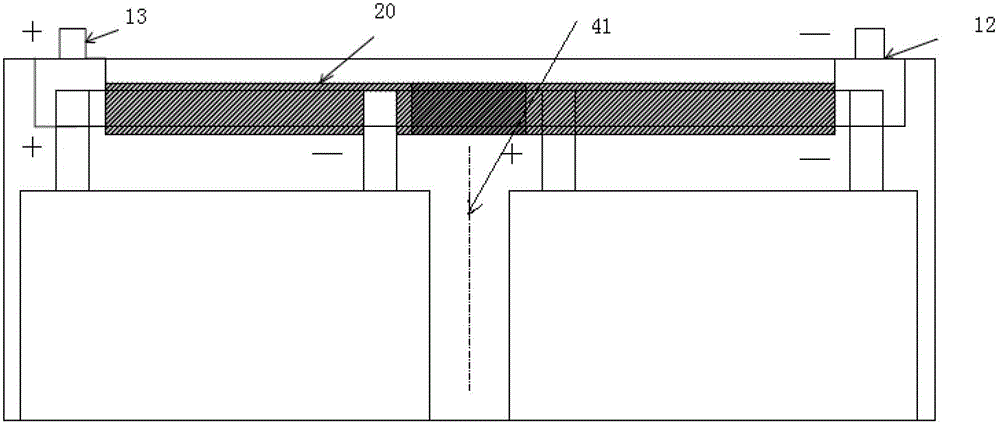

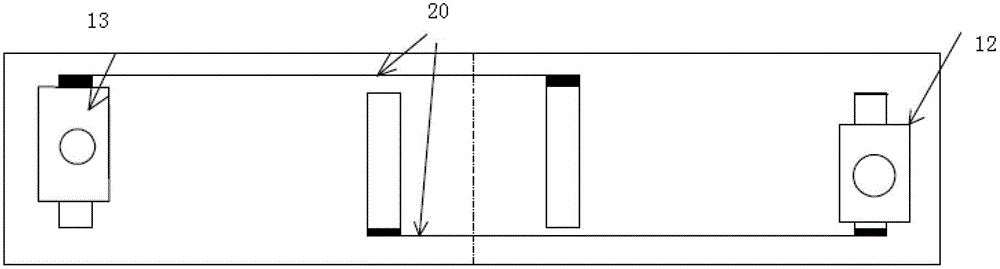

[0025] Please refer to Figure 1-4 , two pole groups are connected in parallel to form a battery cell, and the battery case is described by taking a partition plate to divide the accommodation space of the battery case into two small accommodation spaces of equal size. Such as figure 1 as shown, figure 1 It is an exploded schematic view of each component of a multi-electrode battery according to an embodiment of the present invention. A multi-pole battery pack, including a battery shell shell 40 for containing electric cells, a battery shell upper cover 10 for encapsulating the battery shell shell, the battery shell upper cover includes positive and negative poles 13 and 12, placed in the battery shell The battery cell in the body, the battery shell casing 40 also includes at least one se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com