Biodegradable polymer articles containing oxygen scavenger

A technology for biodegradable and plastic products, applied in the field of biodegradable polymers and their preparation, can solve the problems of wall transparency, decreased mechanical properties, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. Extrusion of PLA film containing iron as oxygen scavenger

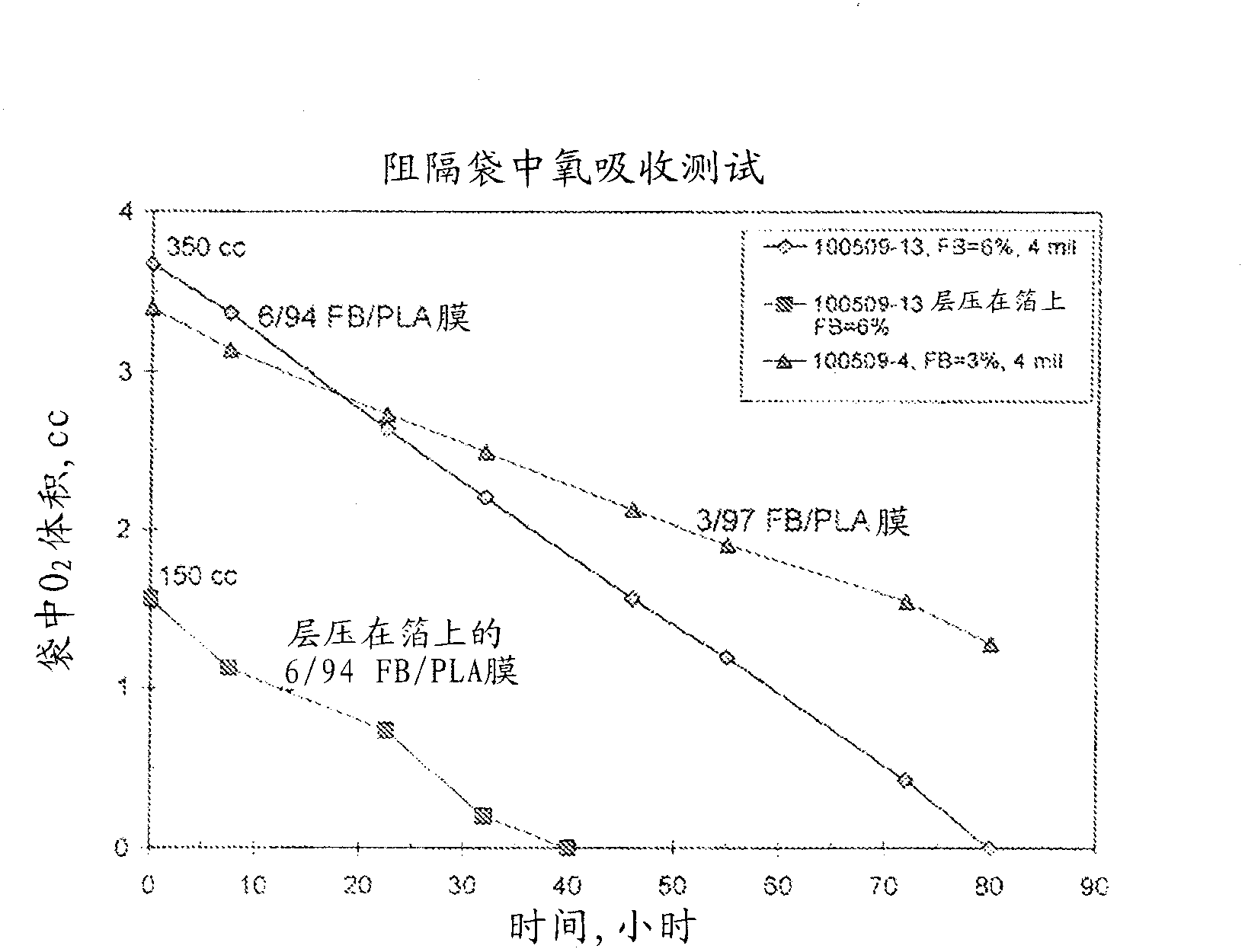

[0034] NatureWorks PLA2002D resin, polylactic acid, was dried in a drying oven at 60°C for 4 hours. Iron, NaCl and NaHSO4 were mixed to form FB according to the method described in patent 6,899,822, US patent applications 2005 / 0205841 and 2007 / 020456 at a weight ratio of Fe / NaCl / NaHSO4=85 / 3 / 12. This blend, FreshBlend (FB), was blended with PLA resin in various proportions and extruded from a twin-screw extruder at an average extruder and die temperature of 220 °C. The extruded film was collected by using a winder to make a film 5" wide and approximately 4 mil thick. The extruded film was used for oxygen removal testing. The film was stored in a 7" container with wet felt wrapped as a source of moisture. x 7" plastic barrier bag. The bag was sealed and filled with 350 or 150 cc of O2 / N2 mixture to achieve an initial oxygen concentration of approximately 1%. The oxygen concentration in the bag over ti...

Embodiment 2

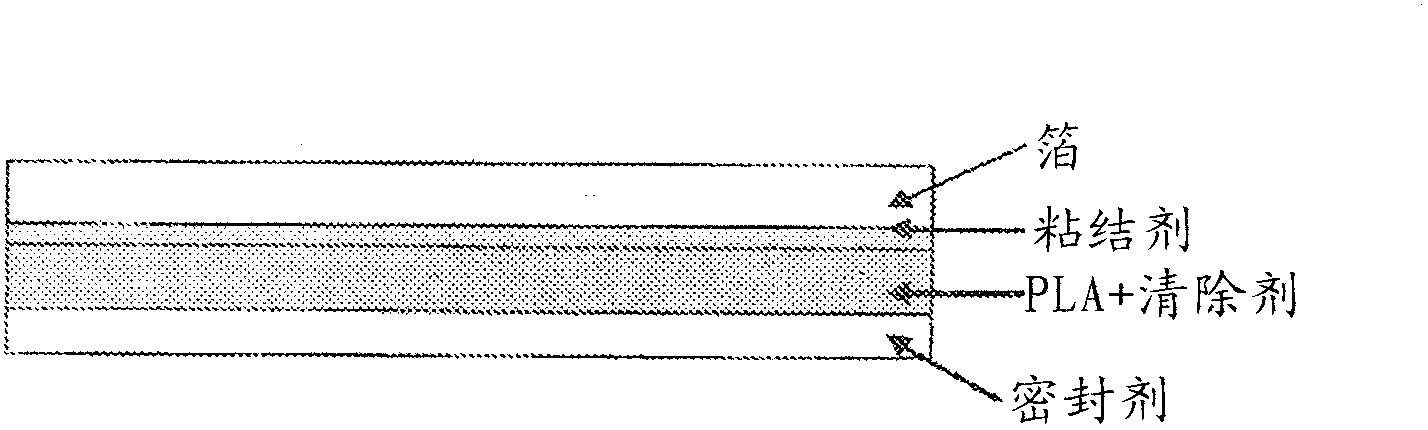

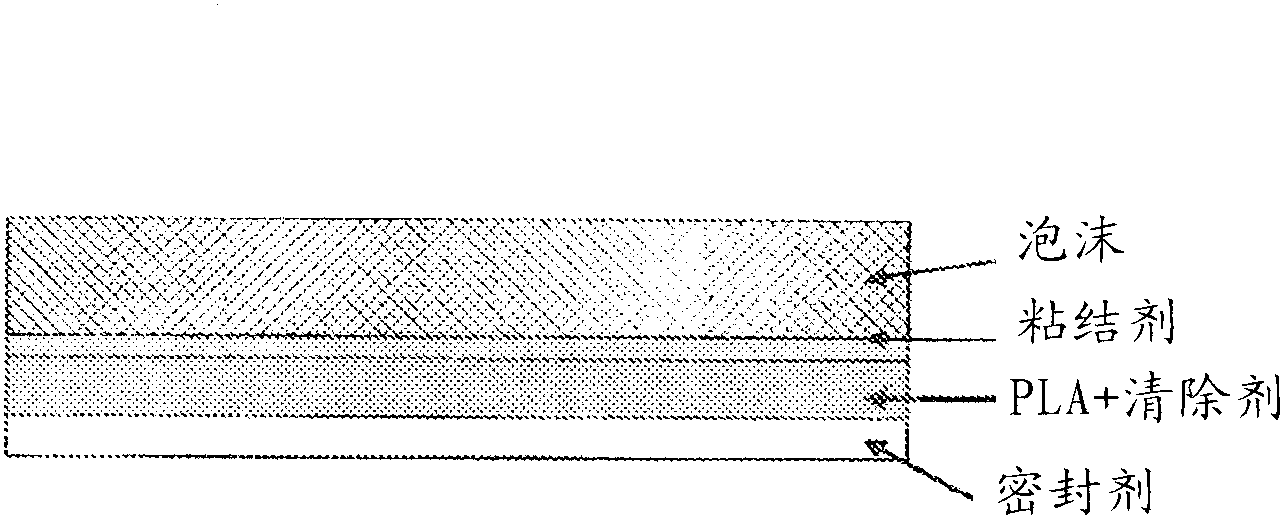

[0036] Example 2. PLA Laminate Containing Oxygen Scavenger

[0037] figure 2 Laminates according to the invention are shown. The PLA film loaded with 6% FB prepared in Example 1 was used for lamination to the foil. Dow Integral TM 801 film was used as the adhesive to make a three-layer laminate of foil / Integral 801 / (FB+PLA) construction, 1 / 1 / 4 mil thick, respectively. The three layers were thermally laminated at about 180°C in a heat seal laminator. Forms a laminate with good adhesion between the layers. The laminate was sealed in a barrier bag with a 0.93 water activity moisture regulator. Under 150cc O2 / N2 mixture and the initial concentration of 1.04% or 1.56cc, the oxygen scavenging behavior is the decrease of oxygen concentration over time for FB / PLA film and laminate as figure 1 shown. Oxygen was exhausted after 40 hours of storage. This demonstrates the oxygen scavenging ability of the laminated structure comprising FB and PLA.

Embodiment 3

[0038] Example 3. Coextrusion of PLA film

[0039]The same raw material was used to coextrude PLA in a 5-layer film structure by utilizing a film coextrusion system. The 5-layer structure is arranged in the order of A / B / C / B / A=LDPE / tie layer / (PLA+FB) / tie layer / LDPE with a thickness ratio of about 5 / 5 / 80 / 5 / 5. The net content of FreshBlend distributed only in layer C is 5wt%. Extrusion was performed at average extruder exit temperatures A = 500F, B = 500F and C = 390F. The LDPE resin is Dow LDPE640I. The tie layer resin was Admer QF551A, maleic anhydride modified polypropylene, and the PLA was NatureWorks 2002D resin. By properly adjusting the extrusion rate and die temperature, 3 and 3.5 mil films consisting of five layers were produced. PLA layer including FreshBlend is expected to be 2-3mil. This indicates the processability of PLA containing iron-based oxygen scavengers to form multilayer structures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com