Gearbox in turbomachine

A technology of turbine engine and gearbox, which is applied in the direction of engine manufacturing, engine components, engine functions, etc., and can solve problems such as the complexity of gearbox design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

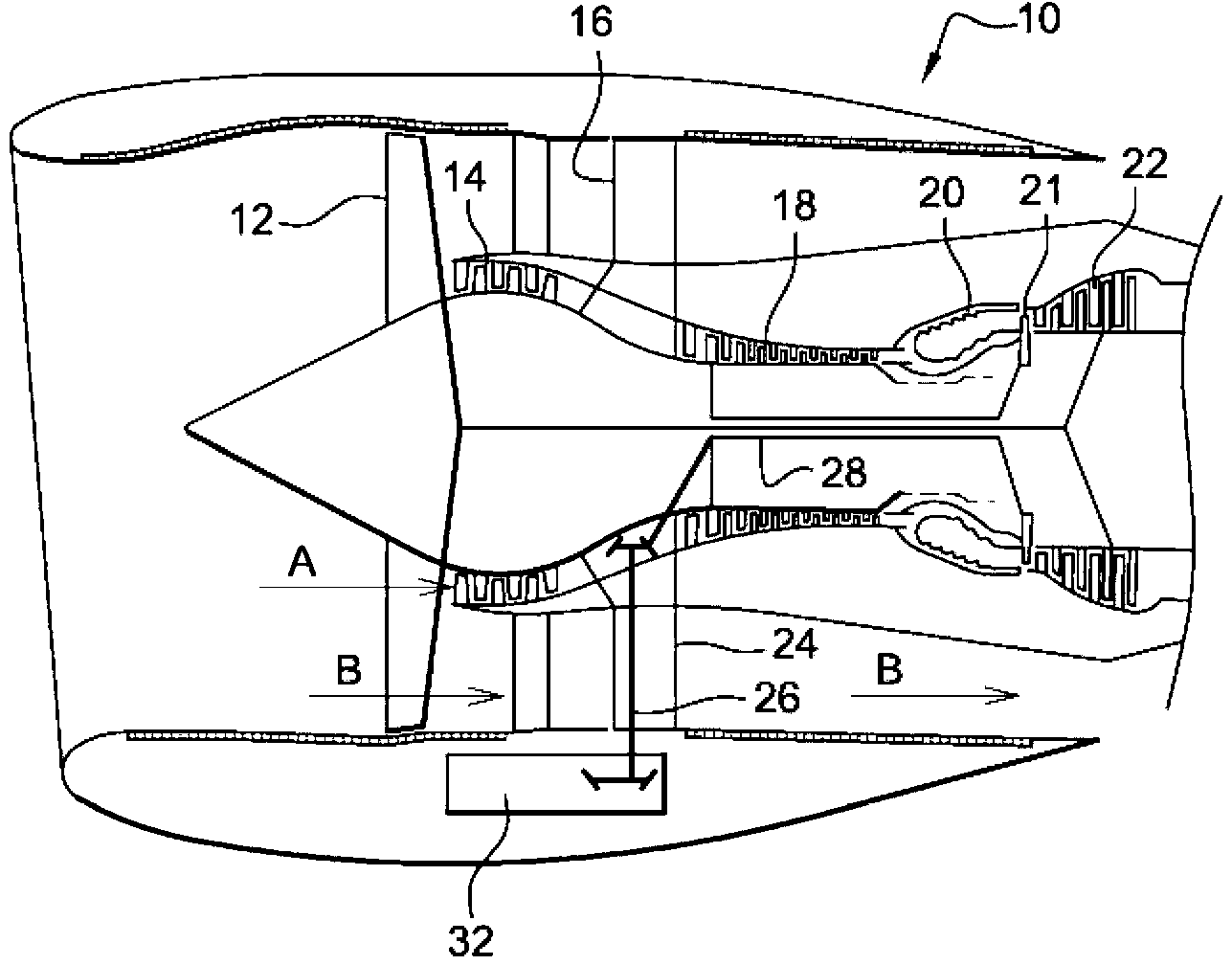

[0027] Referring first to FIG. 1 , there is shown a turbine engine 10 comprising, from upstream to downstream: a fan 12; a low pressure compressor 14; an intermediate casing 16; a high pressure compressor 18; a combustion chamber 20; a high pressure turbine 21; Turbine 22. The air entering the turbine engine is divided into primary airflow (arrow A) and secondary (bypass) airflow (arrow B), the primary airflow flows through the low pressure compressor 14 and the high pressure compressor 18 to the combustion chamber 20, and then flows through the high pressure turbine 21 and low pressure turbine 22, the secondary air flow flows around the compressors 14,18, the combustor 20 and the turbines 21,22.

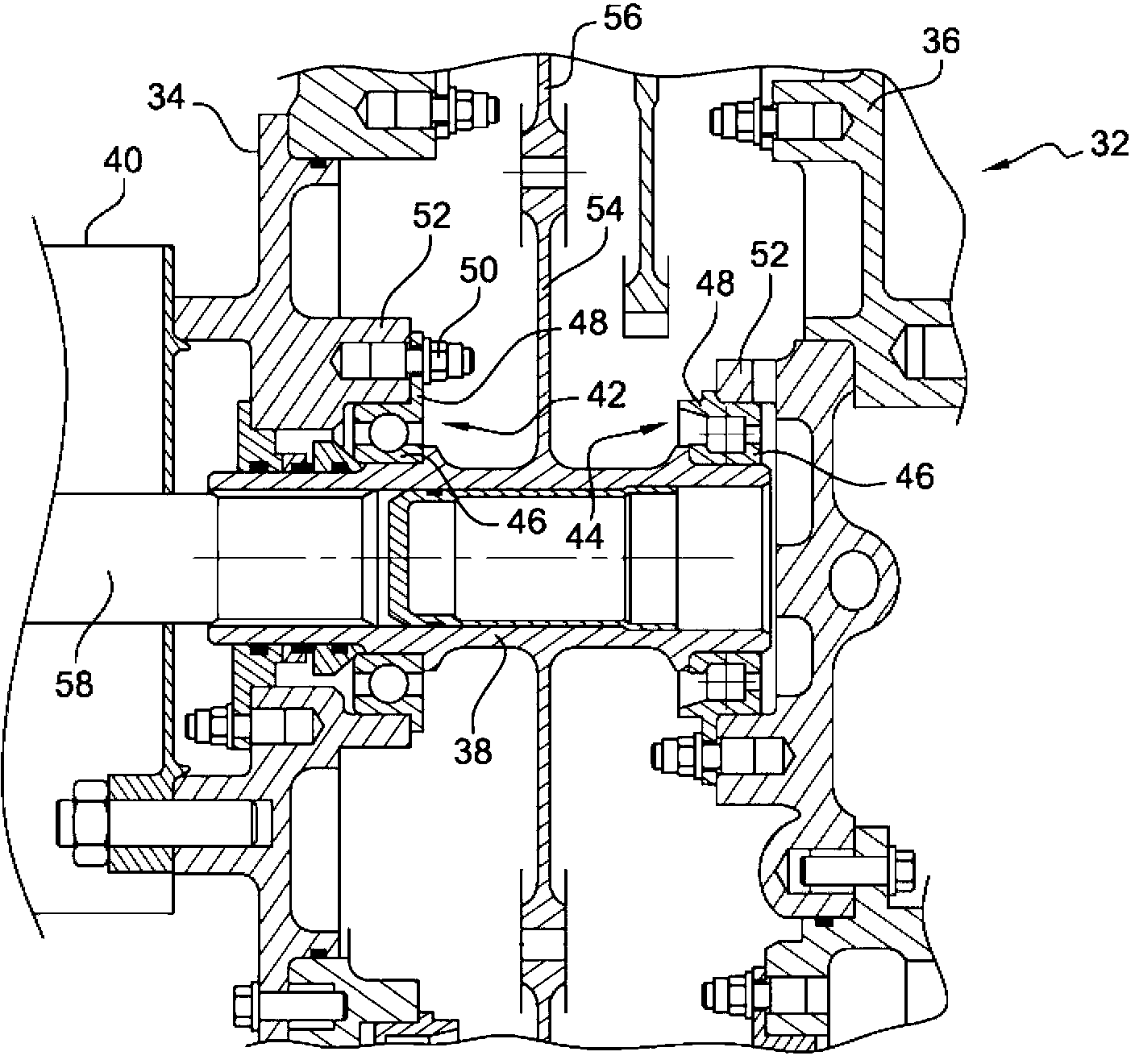

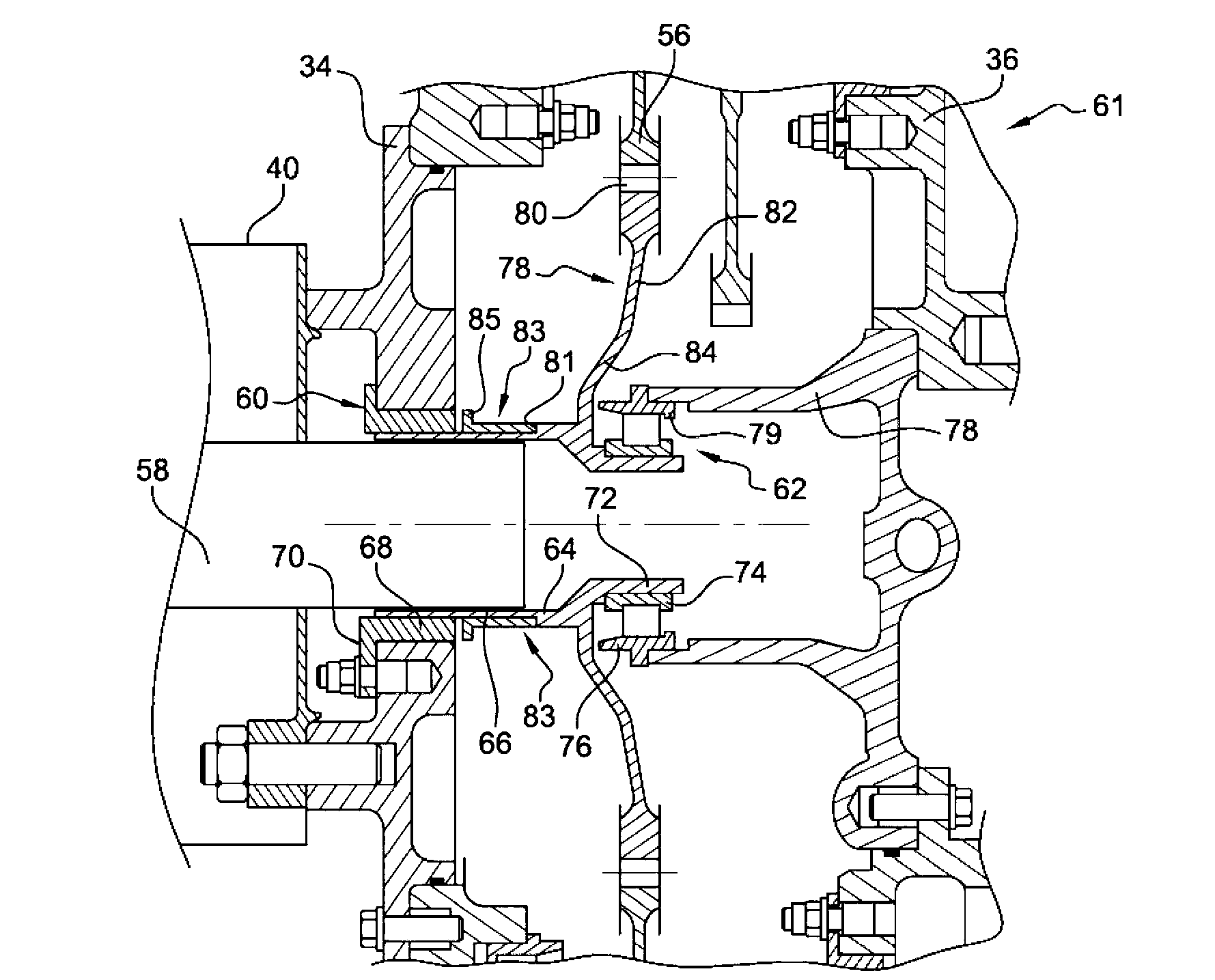

[0028] The intermediate housing 16 has structural arms 24 extending radially outwards. One of the structural arms 24 of the intermediate housing 16 includes a radial shaft 26 whose inner end is connected to a drive shaft 28 of the high pressure compressor 18 via a pair of bevel gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com