Double diaphragm pump

A diaphragm pump and diaphragm technology, applied in the direction of pumps, pumps with flexible working elements, liquid displacement machinery, etc., can solve the problems of increasing pump maintenance costs, and achieve the effect of high service life and reliable switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

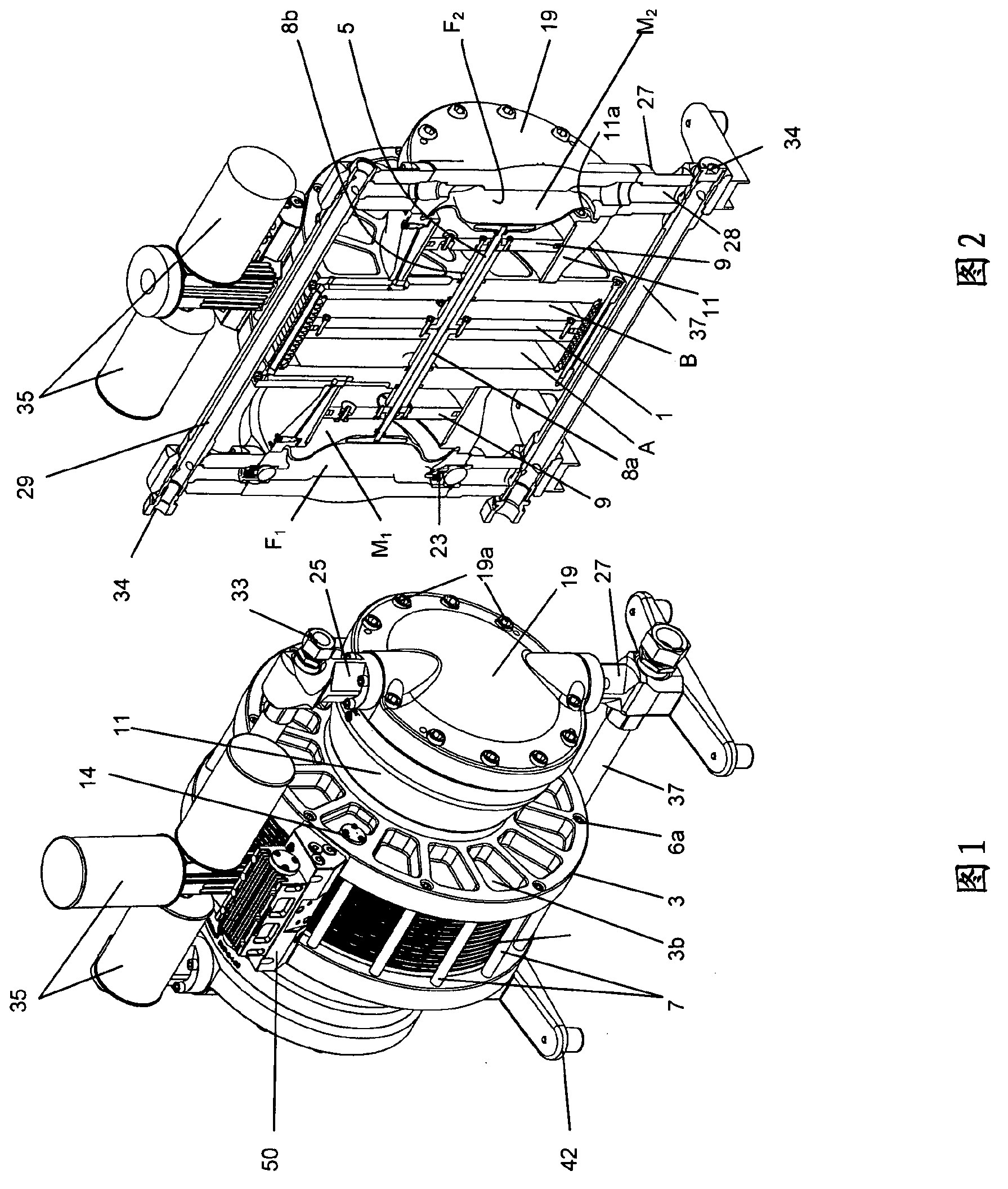

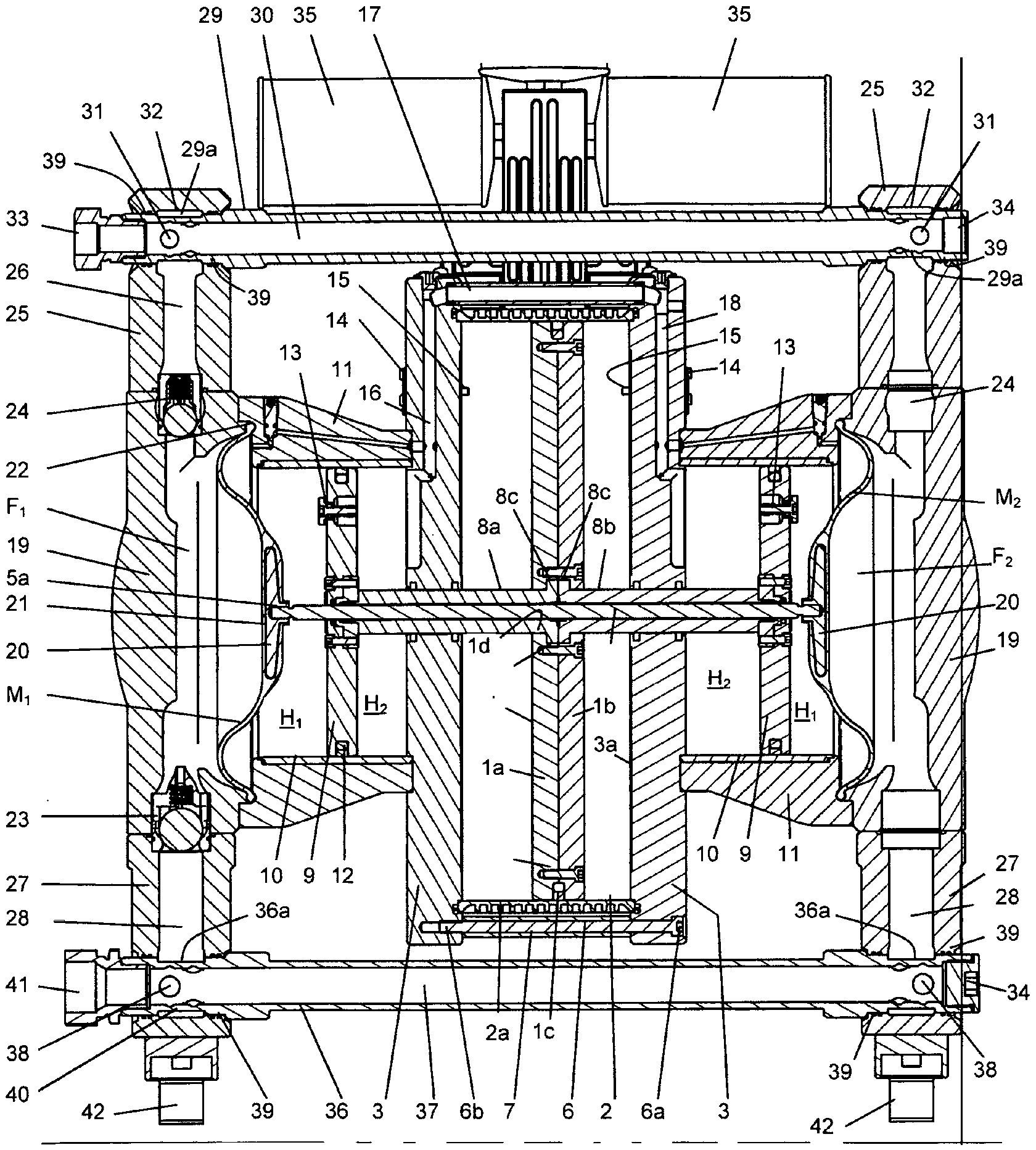

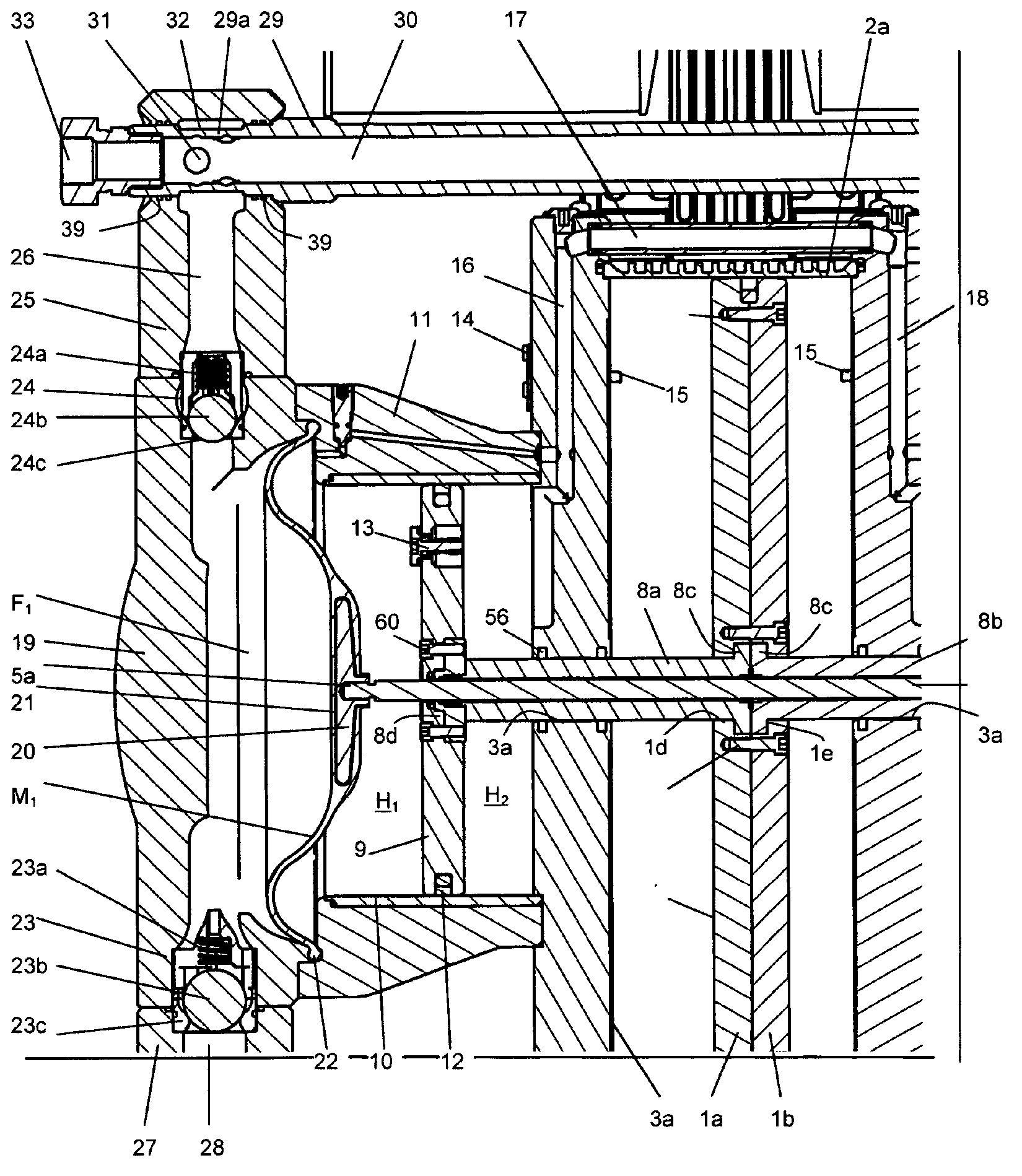

[0036] figure 1 and 2 A perspective view of a diaphragm pump according to the invention in the form of a double diaphragm pump is shown. The double-diaphragm pump has a housing cover 19 and a housing part 11 which accommodates the cylinder 10 of the hydraulically actuated piston-cylinder system 9 , 10 . as in figure 2 , the housing part 11 is fastened to the axial cylinder wall 3 of the first piston-cylinder system by means of coaxial screws 11a. by housing cover 19 and housing part 11 at 22 (see image 3 and 4 ) to clamp the diaphragm M. The housing cover 19 and the housing part 11 are connected to each other by means of bolts 19a and hold the membrane M in position. The housing cover 19 forms a receptacle for the check valve 24 below and above, respectively. The non-return valves 23 , 24 are inserted into corresponding recesses in the housing cover 19 before the housing flanges 25 , 27 are screwed onto the housing cover 19 . The additional seal prevents the delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com