portable cutting machine

A cutting machine, portable technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of poor cutting accuracy, body vibration, very severe vibration, etc., and achieve good operation comfort and precise cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

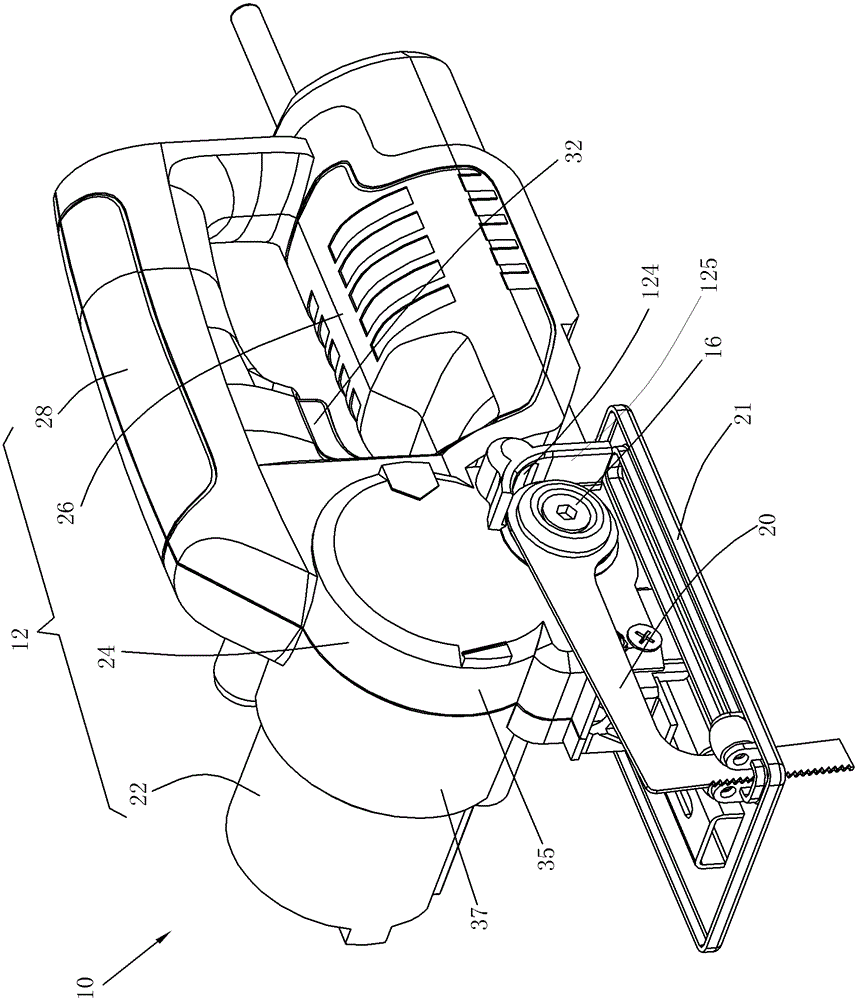

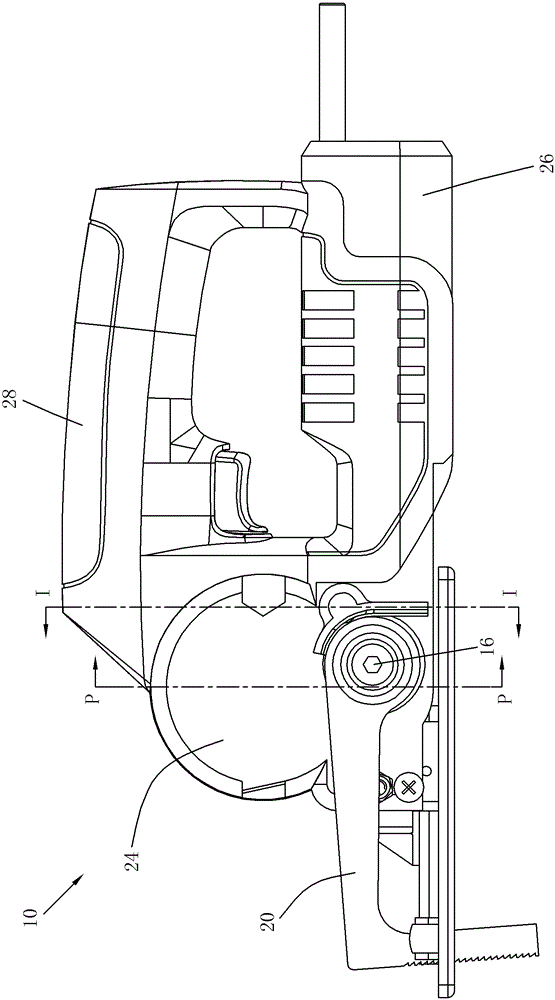

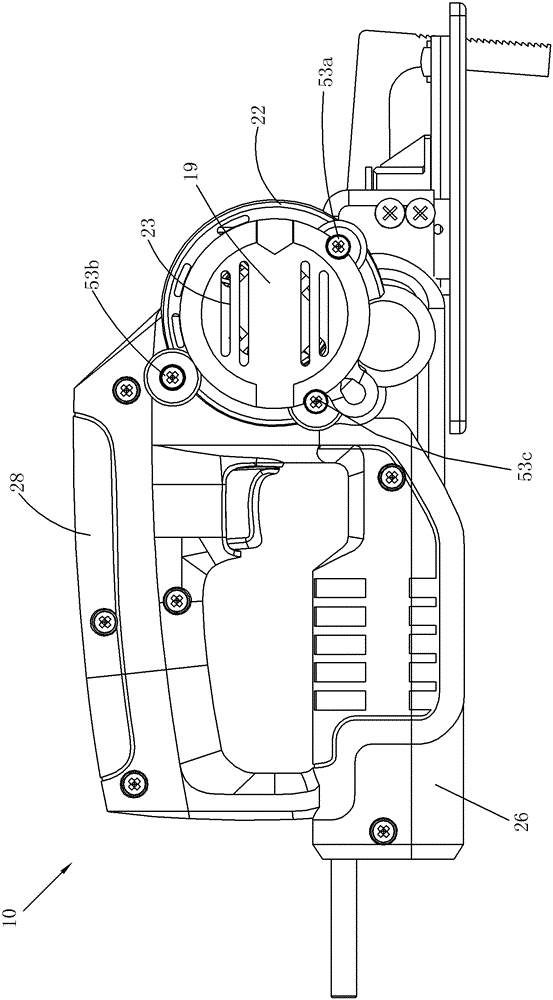

[0091] refer to figure 1 , Figure 5 and Figure 6 , the first embodiment of the present invention provides a portable cutting machine 10 comprising a housing 12, a motor 14 accommodated in the housing 12, a battery pack 15 that provides electric energy for the motor 14, and a swing output shaft 16 driven by the motor 14 , the transmission mechanism 18 between the motor 14 and the swing output shaft 16 is installed on the swing output shaft 16 for the saw blade 20 of the cutting work, and is used to abut against the surface of the workpiece (not shown) to be cut. The portable cutter 10 provides a support assembly 21 for support.

[0092] The housing 12 includes a motor accommodating portion 22 extending longitudinally, a transmission mechanism accommodating portion 24 connected to the motor accommodating portion 22 for accommodating the transmission mechanism 18, a battery pack accommodating portion 26 accommodating the battery pack 15, and the transmission mechanism accommo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com