Operation panel mounting structure of relay sorting AGV carrying trolley

An operation panel and handling trolley technology, applied in transportation and packaging, circuit layout on support structures, motor vehicles, etc., can solve problems such as easy slippage, complex spring force changes, affecting motion control accuracy, etc., and achieve good operating comfort. , Reasonable design of magnet magnetic force, firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

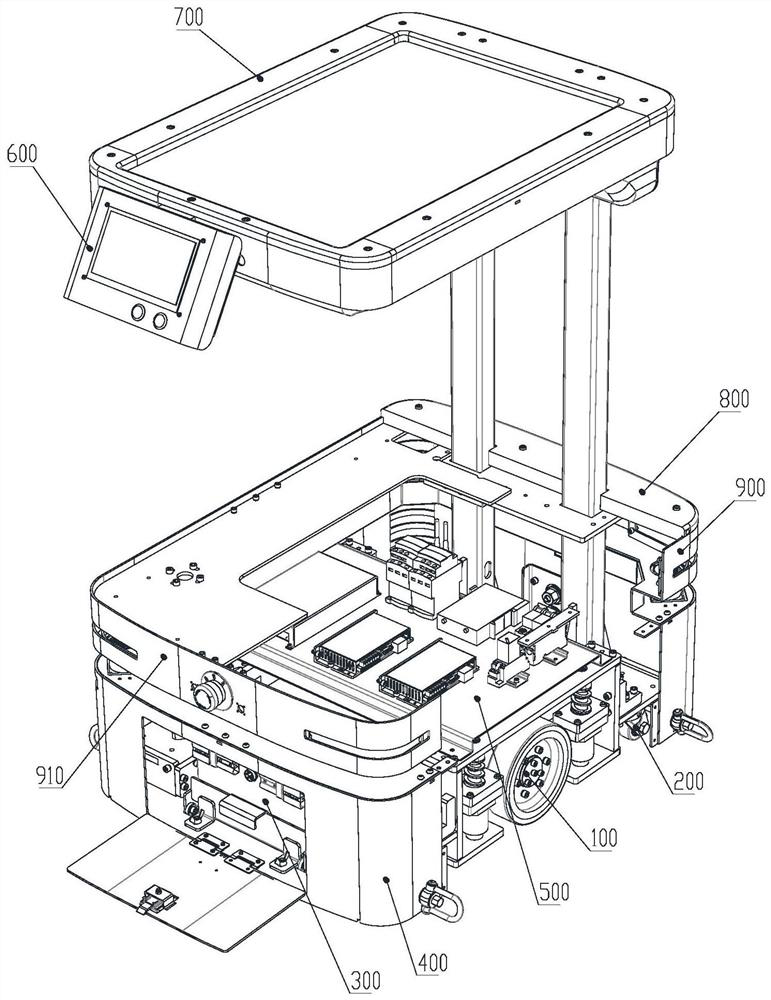

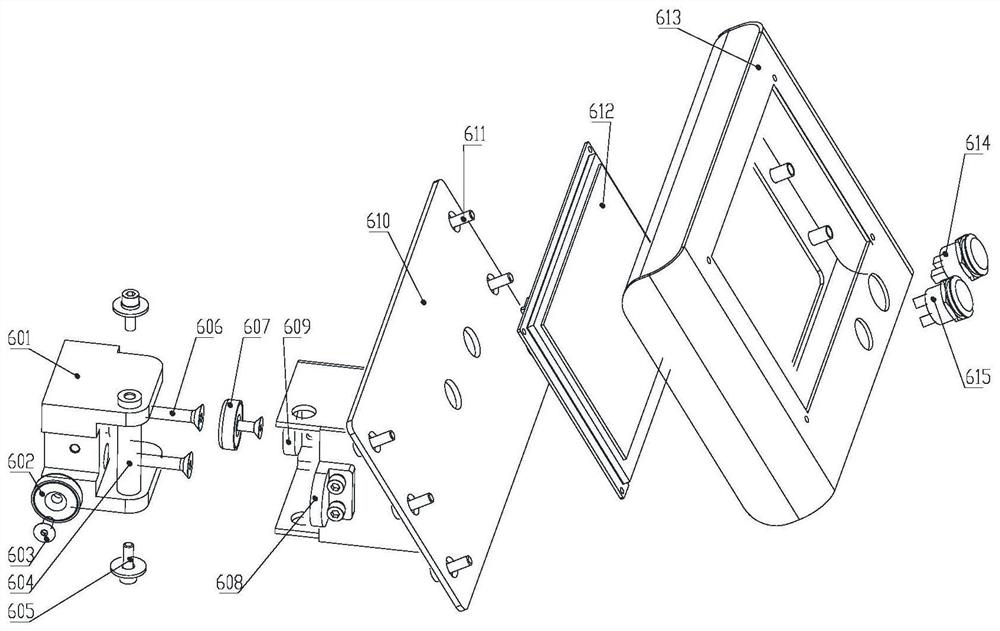

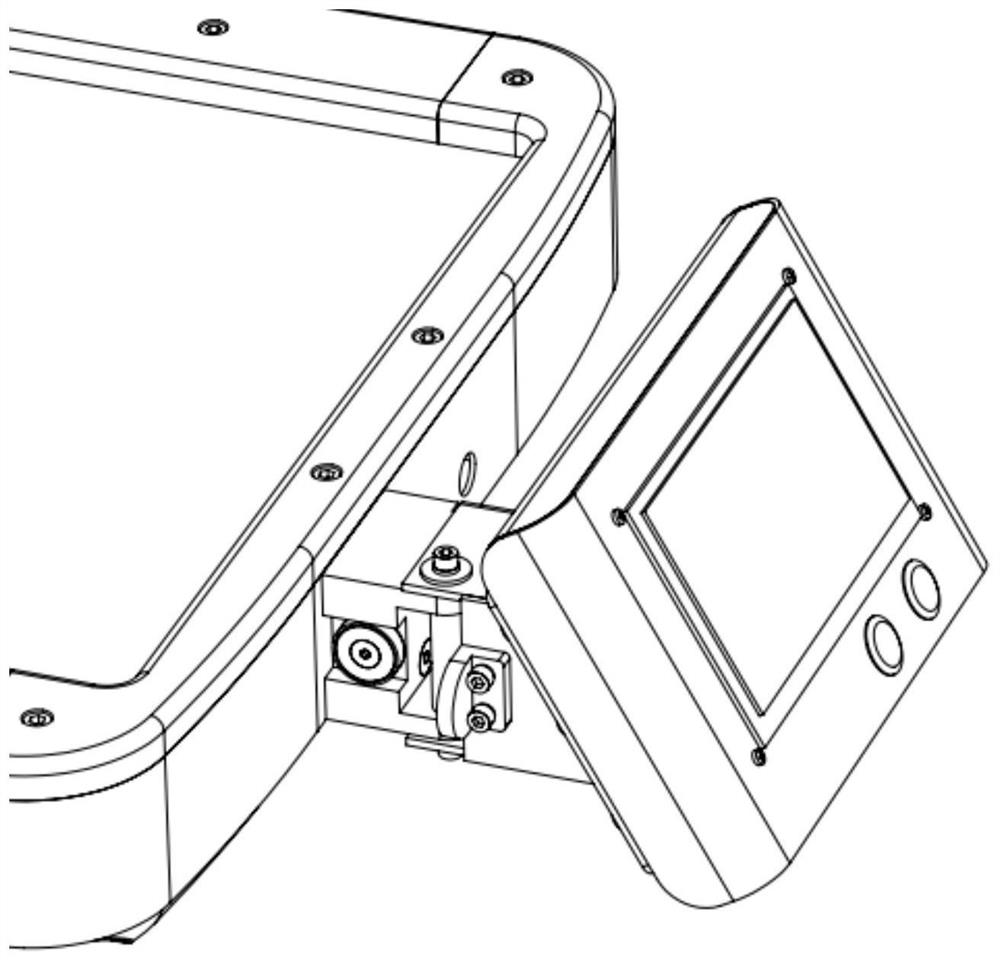

[0020] see figure 1 Relay selection AGV, see figure 1 , including drive assembly 100, universal wheel assembly 200, battery system assembly 300, vehicle frame assembly 400, electrical component assembly 500, operation panel assembly 600, second-layer support plate assembly 700, and first-floor support plate assembly 800, the front shell is welded at 900, and the rear shell is welded at 910. The drive assembly 100, the universal wheel assembly 200, the battery assembly 300, the electrical component assembly 500, and the second-layer support plate assembly 700 are all assembled on the frame assembly 400; the operation panel assembly 600 is assembled on the second-layer support plate Assembly 700 on. The battery system assembly 300 is the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com