General-purpose mechanical handle bar height adjustment mechanism with limiting function

A technology of height adjustment mechanism and manipulator, which is applied in the direction of mechanical control device, control/adjustment system, device for preventing/restricting/restoring the movement of parts of the control mechanism, etc. To solve problems such as poor comfort, to achieve good operating comfort, a wide selection of materials, and to ensure the effect of operating comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

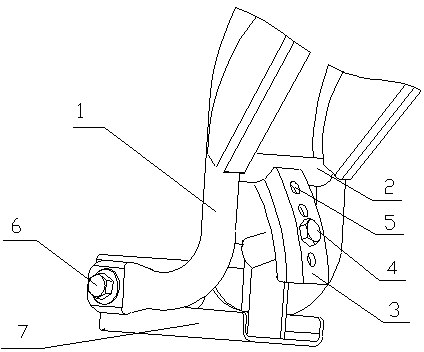

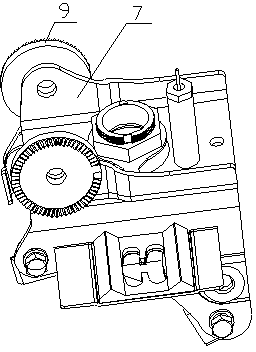

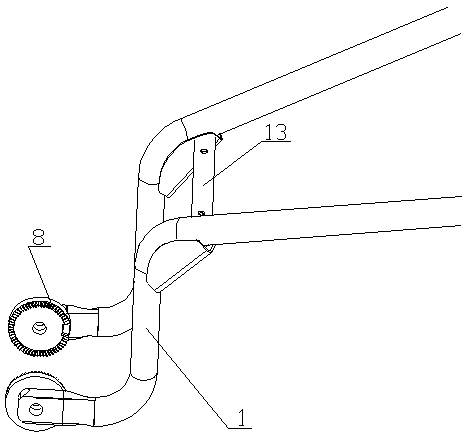

[0024] Such as figure 2 , image 3 and Figure 4 As shown, the height adjustment mechanism of the universal manipulator with limit in the present invention includes the left and right handle tubes 1 and the handle tube upper seat 7, and the middle positions of the left and right handle tubes 1 are connected together by the upper beam 13. The inner sides of the lower ends of the left and right handlebars 1 are respectively fixed with coaxial umbrella-shaped toothed discs 8 , and the tooth surfaces are located on the inner side and opposite to each other. The outer sides of the upper seat 7 of the handle tube are respectively fixed with fixed umbrella-shaped toothed discs 9, the tooth surfaces of the fixed umbrella-shaped toothed discs are located on the outside, and the left and right pairs of fixed umbrella-shaped toothed discs and movable u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com