Vegetable cutter

A vegetable cutting machine and switching mechanism technology, applied in metal processing, etc., can solve the problems of high labor intensity, high price, single function, etc., and achieve the effect of increasing fun and entertainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

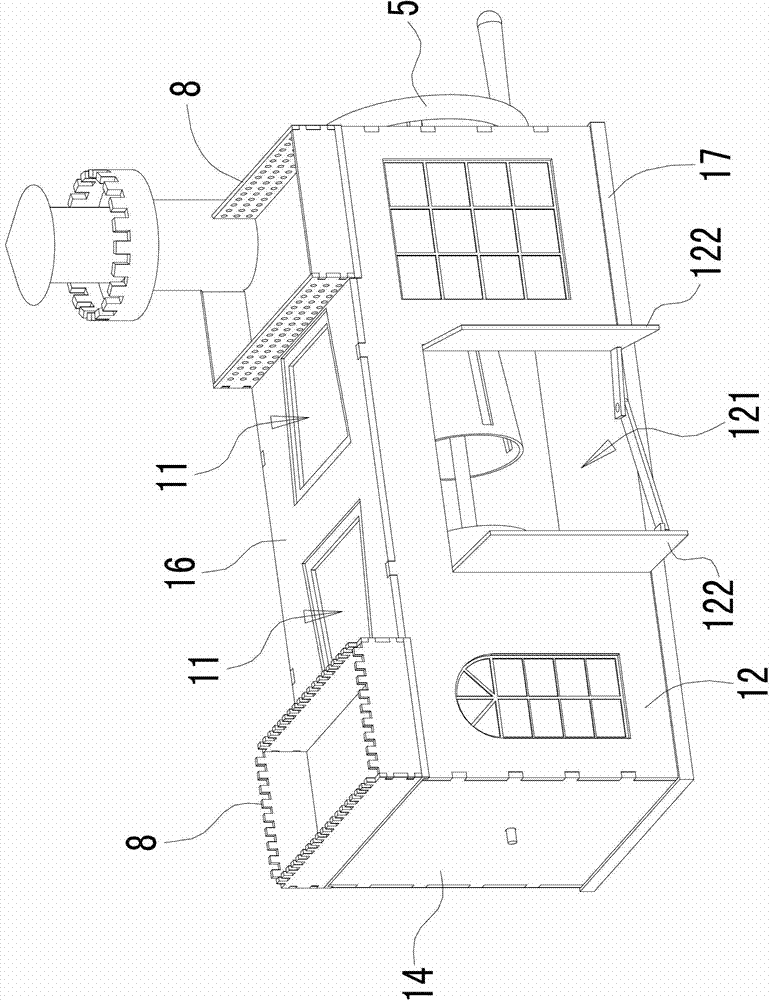

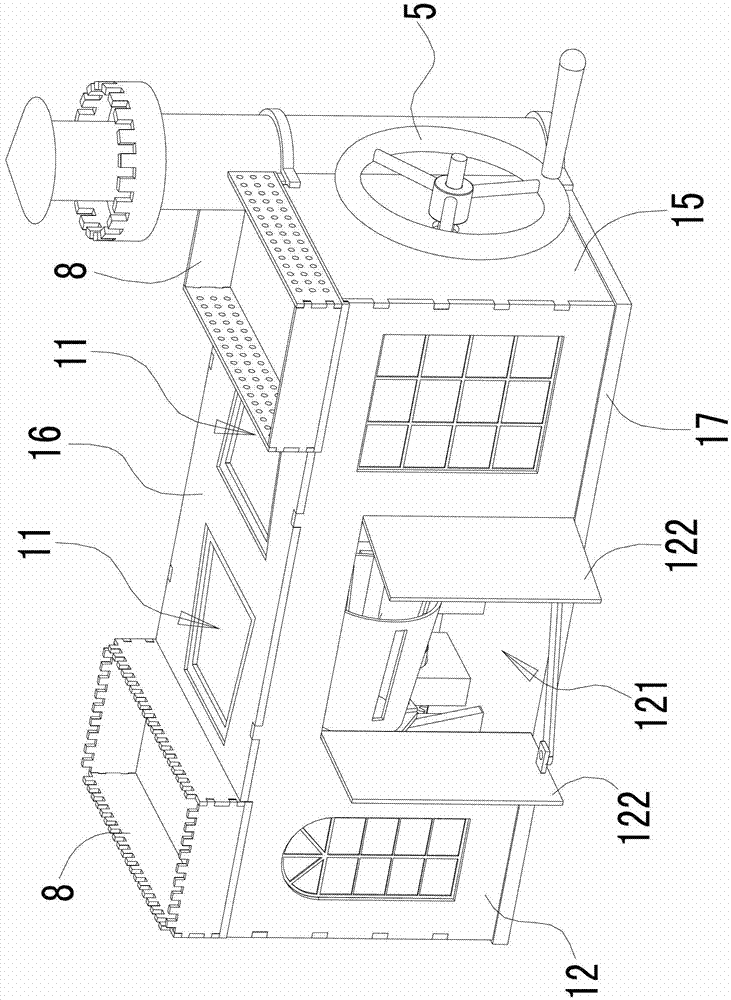

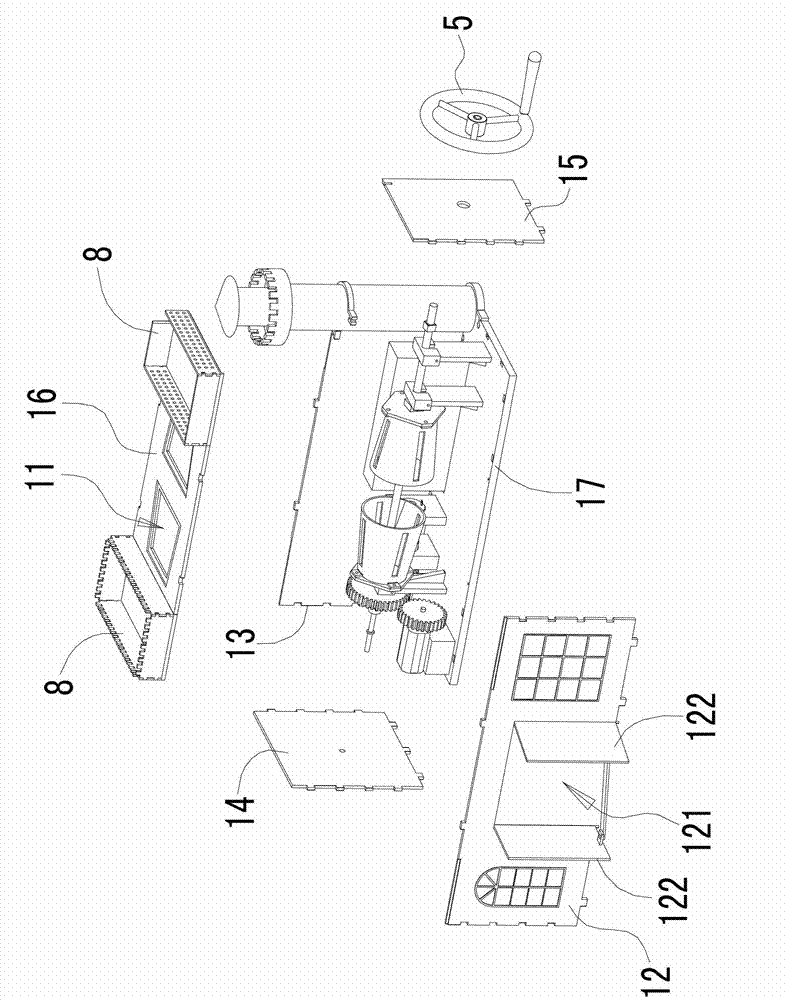

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1 to Figure 13 As shown, a vegetable cutting machine includes a frame, a main shaft 2 and a knife rest 3, the top of the frame is provided with a feed port 11, the main shaft 2 is pivotally mounted on the frame and is positioned under the feed port 11, and the knife rest 3 Installed on the main shaft 2 and driven by the main shaft 2 to rotate, the knife rest 3 is equipped with a blade (not shown) that can cut vegetables sent from the feed port 11 when the knife rest 3 rotates;

[0034] A motor 4 is installed on the frame, the output shaft of the motor 4 is equipped with a first gear 41, one end of the main shaft 2 is equipped with a hand handle 5, and the other end of the main shaft 2 is equipped with a motor that can slide axially along the main shaft 2 and fix it circumferentially. The second gear 21, that is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap