Ceramic chip and manufacturing method thereof

A technology of tile and spray granulation, applied in the field of building ceramics production, can solve the problems of broken glaze and excessively large three-dimensional texture concavities and convexities, and achieves the effects of high cost, rich decorative effects, and alleviation of cracking defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

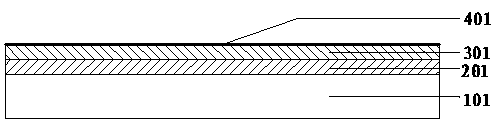

[0036] Refer to attached figure 1 , the present embodiment provides a kind of tile product, and its order from bottom to top is green body layer 101, bottom glaze layer 201, surface glaze layer 301, printing layer 401, and wherein the thickness of bottom glaze layer is about 0.2mm, and surface glaze layer The layer thickness is about 0.1 mm.

[0037] The preparation method includes the following steps.

[0038] (1) Raw materials are ball milled to remove iron.

[0039] In this step, the conventional formula in the tile production technology can be selected. That is to say, the raw materials with feldspar, quartz, clay, talc and other conventional raw materials as the main components are ball milled, iron removed and stale homogenized.

[0040] (2) Spray granulation.

[0041] The stale homogenized slurry after iron removal in step (1) is put into the spray drying tower for spray granulation, and after spray granulation, granular powder is formed, and the moisture content of...

Embodiment 2

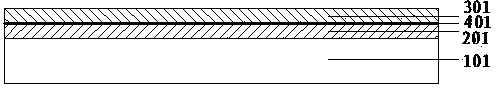

[0062] Refer to attached figure 2 , the present embodiment provides a kind of tile product, and it is body layer 101, bottom glaze layer 201, printing layer 401, surface glaze layer 301 successively from bottom to top, wherein the thickness of bottom glaze layer is 0.4mm, and the thickness of surface glaze layer is 0.4mm. 0.2mm, the top glaze layer is transparent glaze.

[0063] The preparation method of this embodiment is basically the same as that of Example 1, except that: 1. The amount of glaze used for spraying glaze on the bottom glaze layer is about double that of Example 1. 2. After the bottom glaze layer is formed, first perform inkjet printing to form the printing layer 401, and then spray the surface glaze layer. The surface glaze layer is transparent glaze, and the thickness of the surface glaze layer is 0.2mm. The transparent glaze dry material components are: 95% transparent frit produced by Guangdong Sanshui Dahong Glaze Co., Ltd., and 5% kaolin. When ball mi...

Embodiment 3

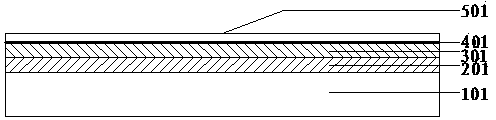

[0066] Refer to attached image 3 , in order to protect the printing layer, the present embodiment provides a kind of tile product, which is successively green body layer 101, bottom glaze layer 201, surface glaze layer 301, printing layer 401, transparent glaze protection layer 501 from bottom to top, wherein The thickness of the bottom glaze layer 201 is 0.1 mm, the thickness of the top glaze layer 301 is matt glaze, and its thickness is 0.05 mm, and the thickness of the transparent glaze protective layer 501 is 0.1 mm.

[0067] Its preparation method is basically the same as that of Example 1, except that the amount of bottom glaze and top glaze is about half of that of Example 1, and its thickness is also half of that of Example 1. Add a step of applying a transparent glaze protective layer on the printing layer, and the components of the transparent glaze are the same as those in Example 2. The dosage is about 15.5g / tablet.

[0068] In this embodiment, although a step o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com