Large-size Zr standard crystal material and preparation method thereof

A large-scale, benchmark technology, applied in the field of quasicrystal materials and their preparation, can solve the problems of complex process, unfavorable understanding of the formation mechanism of Zr benchmark crystal materials, and unfavorable application of Zr benchmark crystal materials, etc., and achieves a simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The selected alloy composition is Zr 64 Ti 6 Cu 13.5 Ni 8.5 Al 8 (atomic percent).

[0035] The smelting method of the master alloy of the present invention adopts the electric arc melting technology. The raw materials are Zr, Ti, Ni, Cu, and Al high-purity metals (purity not less than 99.9wt.%), and the master alloy ingot is melted by electric arc. First evacuate the working chamber to 10 -3 ~10 -4 Pa, then pass into high-purity argon gas (purity is 99.99wt.%) for smelting; before smelting alloy, Ti metal ingot is melted at first, forms titanium oxide by oxidation reaction to further reduce the partial pressure of oxygen in the working chamber; To ensure that the composition of the alloy ingot is as uniform as possible, each alloy ingot needs to be smelted 4 times. Take 20g of alloy ingot and put it into the crucible of tilting casting equipment, vacuumize the working chamber to 10 -3 ~10 -4Pa, and then arc melting, after the alloy is completely melted, tilt ...

Embodiment 2

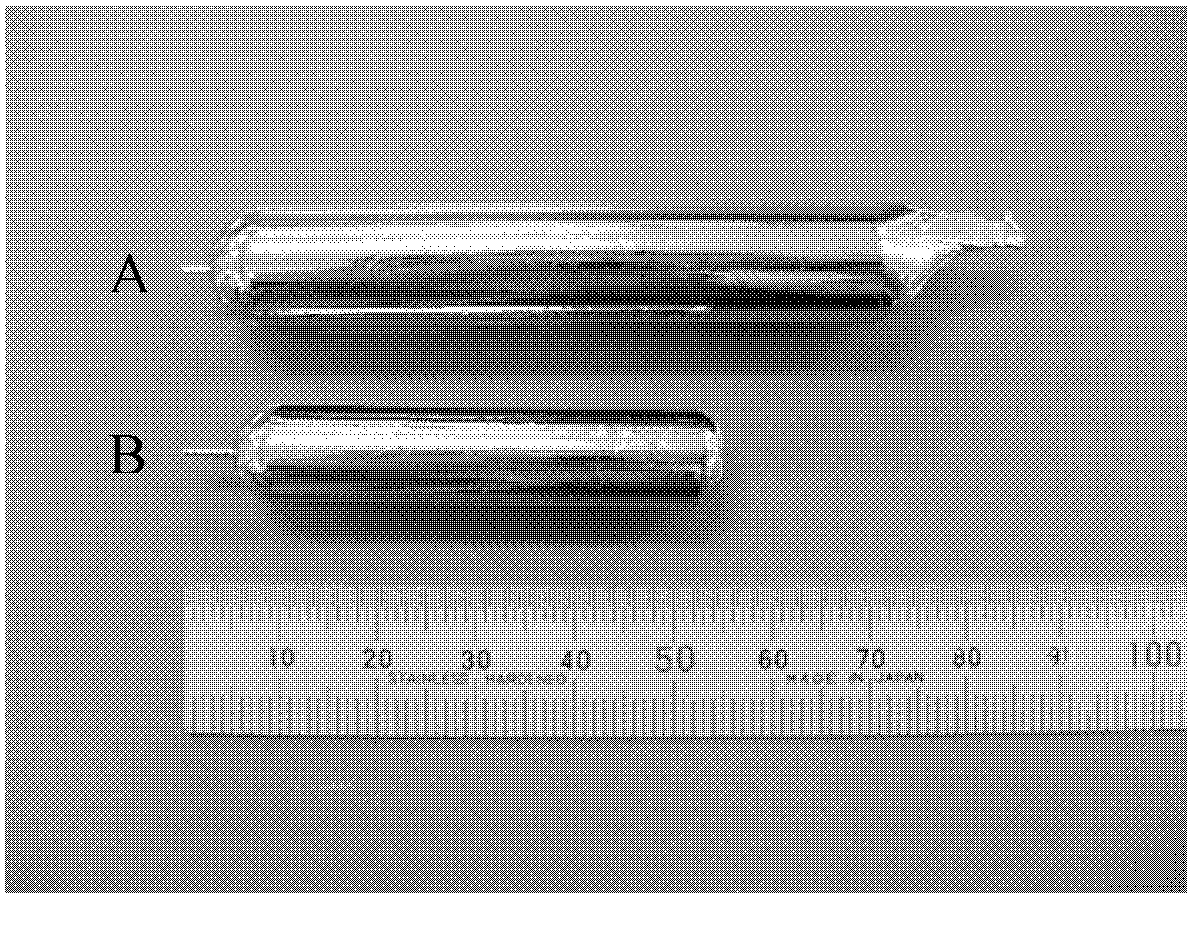

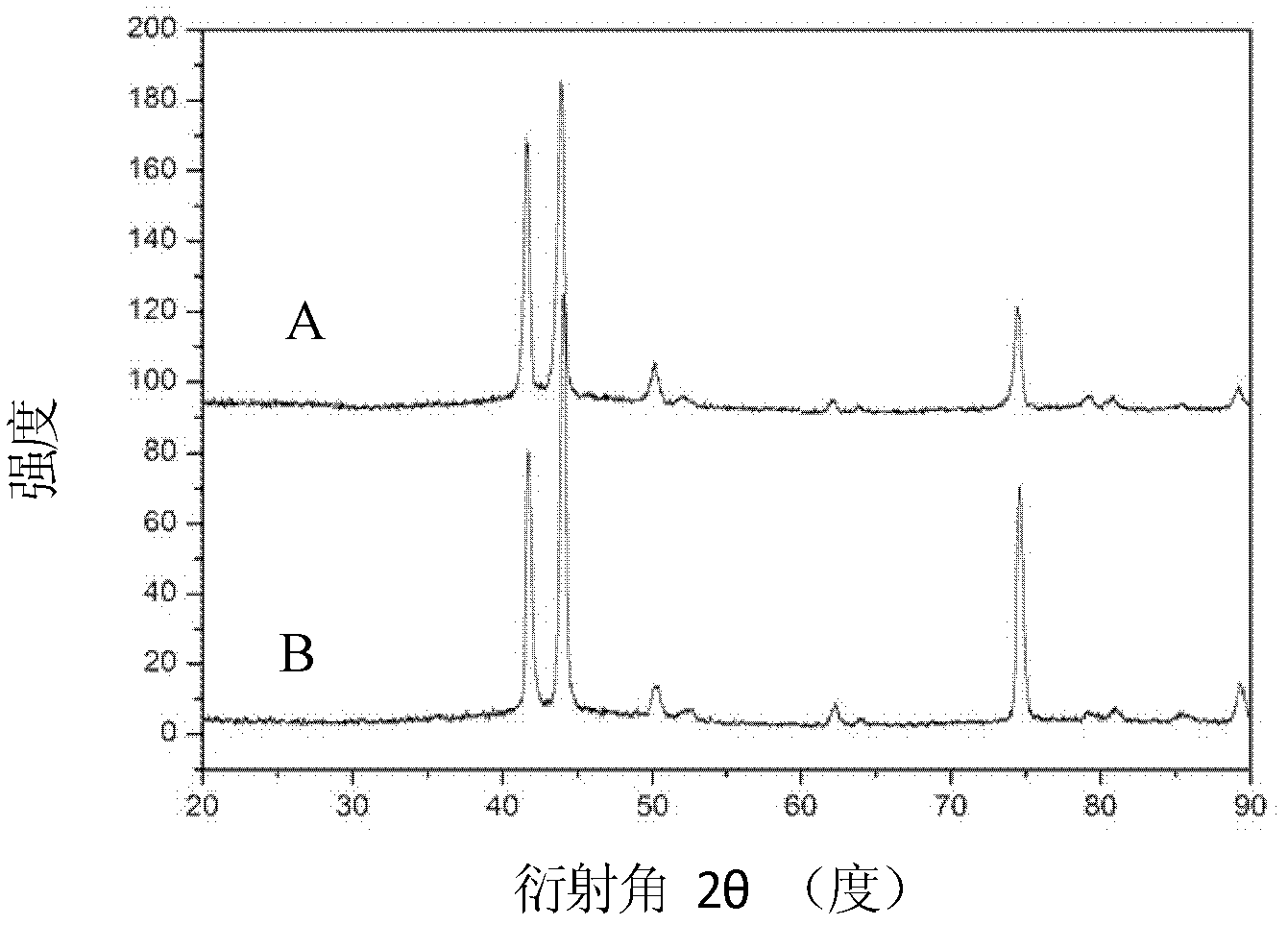

[0037] The difference from Example 1 is that the alloy composition is Zr 62 Ti 8 Cu 13.5 Ni 8.5 Al 8 (atomic percent); figure 1 B is the photo of the quasicrystal sample with a diameter of 8mm in this embodiment, Figure 5 The X-ray diffraction results of the as-cast samples with diameters of 6 mm and 8 mm in this example show that the samples are mainly composed of quasi-crystalline phases.

Embodiment 3

[0039] The difference from Example 1 is that the alloy composition is Zr 60 Ti 10 Cu 13.5 Ni 8.5 Al 8 (atomic percent); diameter is 2mm sample adopts copper mold spray-casting method to prepare, gets 5g alloy ingot and puts into quartz crucible, the working cavity is evacuated to 10 -3 ~10 -4 Pa, then carry out induction melting, after the alloy is completely melted (alloy melt temperature is higher than 1250 ° C), use argon to spray the alloy melt into the copper mold, and obtain a cast sample with a diameter of 2 mm (cooling rate is about 10 2 K / s).

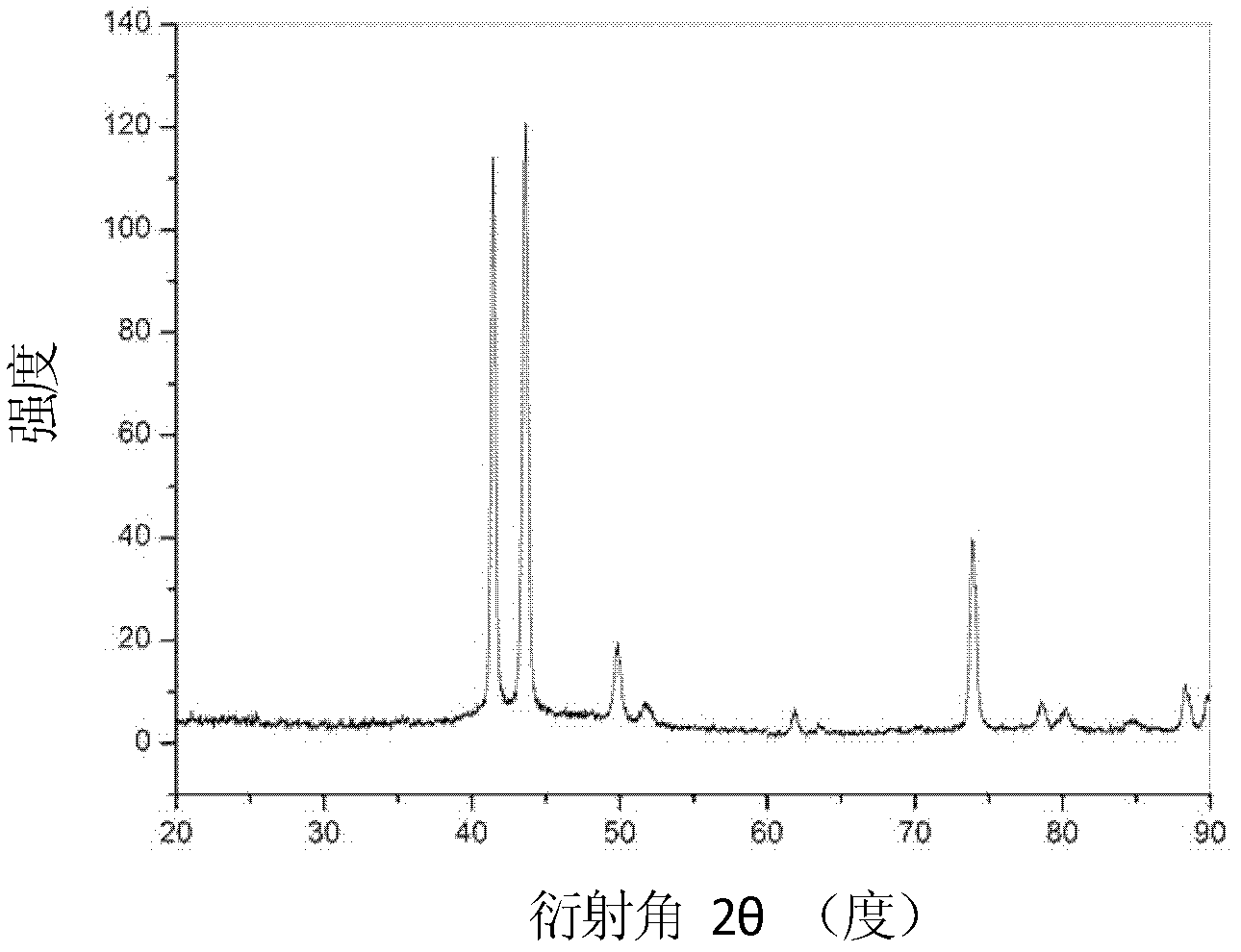

[0040] image 3 Middle curve A and Figure 4 Photo A in the middle is the corresponding X-ray diffraction result and transmission electron microscope analysis result, which shows that the sample is mainly composed of quasicrystals. It can be found that the volume fraction of quasicrystals is higher than 90% by analyzing transmission electron microscope photos.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com