A kind of large-size zrti reference crystal material and preparation method thereof

A large-scale, benchmark technology, applied in the field of large-scale ZrTi benchmark crystal alloys and their preparation, can solve the problems of high cooling rate requirements, unfavorable for the application of ZrTi benchmark crystal materials, and difficulty in obtaining pure quasicrystals, and achieves a simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

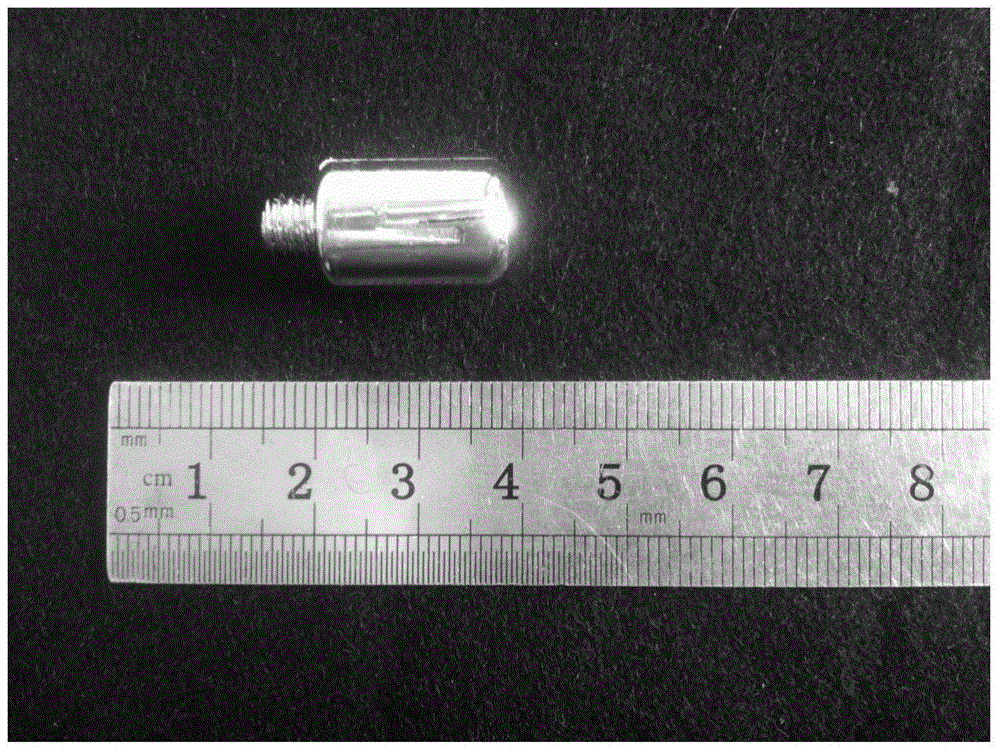

[0023] By preparing 12 mm (Ti 40 Zr 40 Ni 20 ) 84 be 16 The present invention will be described in detail by taking a quasi crystal bar as an example.

[0024] According to Ti 40 Zr 40 Ni 20 (Atomic percentage) Component distribution: Mix the required elemental raw materials (with a purity not lower than 99.9 wt%), and then add them to a vacuum electric arc furnace. Before smelting the alloy, the equipment is vacuumed until the vacuum degree reaches 6×10 -4 During Pa, fill high-purity argon gas (purity is 99.99wt%) to the electric arc furnace cavity inner pressure is 6 * 10 4 Melting starts at Pa. Before smelting the alloy, first melt the titanium ball, absorb oxygen through oxidation reaction for 1 minute, and then melt the raw material under the protection of argon, with a melting current of 200-300 amperes, and cool it in a water-cooled copper crucible when all the solid matter is melted into liquid. Get the composition as Ti 40 Zr 40 Ni 20 master alloy ingots....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com