Endogenous ductile phase reinforced ti-based amorphous composite material and preparation method thereof

An amorphous composite material and a composite material technology, which is applied to the design and preparation of an endogenous toughness β-Ti solid solution reinforced Ti-based amorphous composite material, can solve problems such as poor plasticity and toughness, and achieve the effect of a simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The alloy composition of Ti-based amorphous composites is Ti 44.3 Zr 32.7 Ni 3.2 Cu 6.2 be 13.6 (Atomic percentage), denoted as AT340. The Ti and Zr in the raw materials are sponge Ti and sponge Zr with industrial purity, and the purity of the other elements Cu, Ni and Be is higher than 99.8wt%. The master alloy ingot was prepared by smelting. In order to ensure the uniformity of the smelted alloy ingot, the alloy ingot was repeatedly smelted four times. 10g of the master alloy ingot was induction melted in an inert gas atmosphere, and spray-cast into a hole with a diameter of 5mm in a copper mold to obtain a quenched sample with a diameter of 5mm.

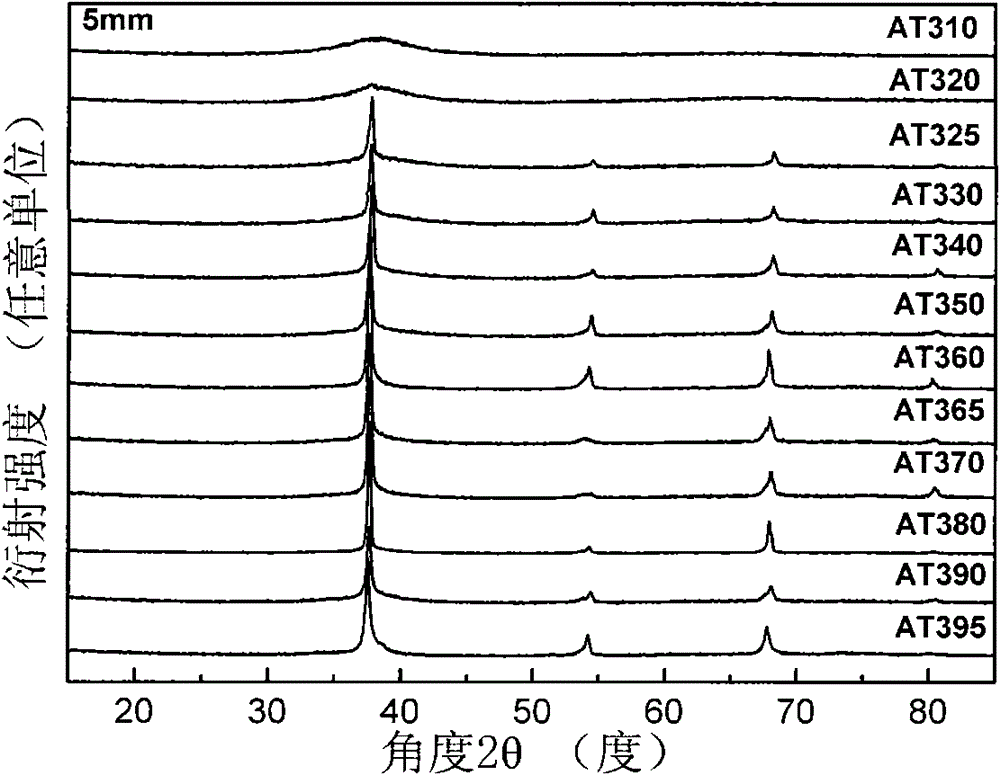

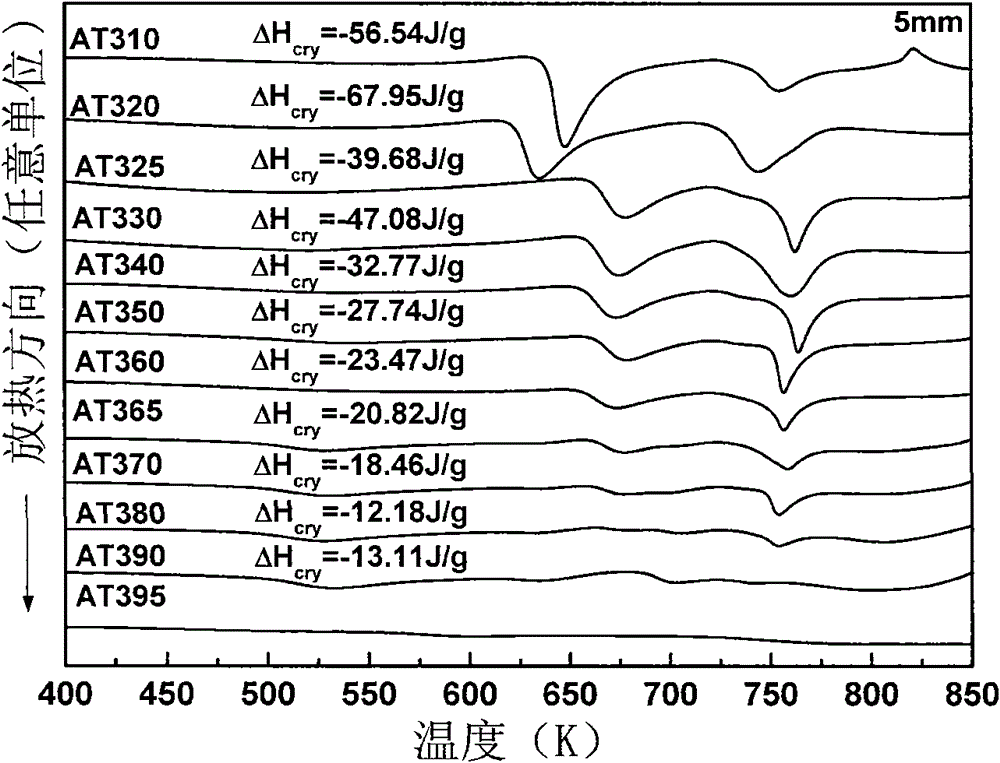

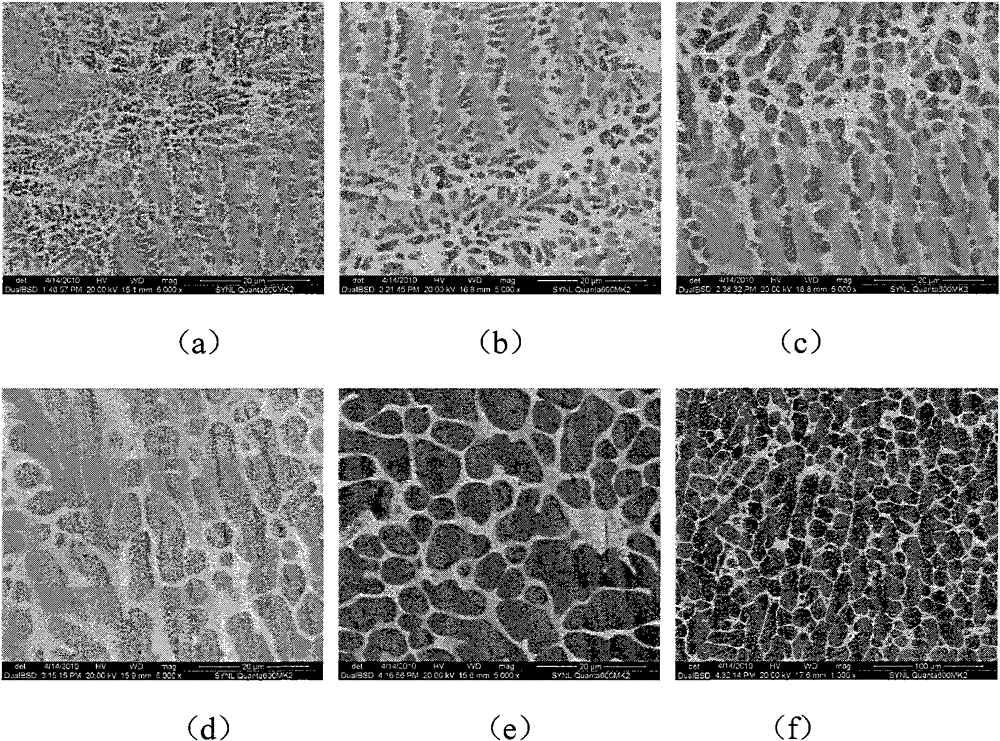

[0030] Depend on figure 1 and figure 2 Visible, Ti 44.3 Zr 32.7 Ni 3.2 Cu 6.2 be 13.6 It is a β-Ti solid solution reinforced Ti-based amorphous composite material with a crystallization enthalpy of -32.77J / g. In the β-Ti solid solution reinforced Ti-based amorphous composite material of this embodiment, the si...

Embodiment 2

[0035] The difference from Example 1 is that the alloy composition of the Ti-based amorphous composite material is Ti 45.7 Zr 33.0 Ni 2.9 Cu 5.9 be 12.5 (Atomic percentage), denoted as AT345.

[0036] Ti 45.7 Zr 33.0 Ni 2.9 Cu 5.9 be 12.5The alloy is β-Ti solid solution reinforced Ti-based amorphous composite material. In the β-Ti solid solution reinforced Ti-based amorphous composite material of this embodiment, the size of the β-Ti solid solution is 2-5 μm, and the volume fraction is about 45%. The compressive yield strength of the composite material is 1500-1600MPa, the compressive breaking strength is 1700-2100MPa, the compressive strain is 5±2%, the tensile yield strength is 1400MPa, the tensile breaking strength is 1500MPa, and the tensile strain is 4±2%.

Embodiment 3

[0038] The difference from Example 1 is that the alloy composition of the Ti-based amorphous composite material is Ti 35.7 Zr 30.8 Ni 4.8 Cu 8.3 be 20.4 (atomic percentage), denoted as AT310. Depend on figure 1 It can be seen that the quenched Ti with a diameter of 5mm 35.7 Zr 30.8 Ni 4.8 Cu 8.3 be 20.4 The alloy structure is pure amorphous structure, and the crystallization enthalpy value is -56.54J / g.

[0039] In this embodiment, the properties of the Ti-based amorphous composite material alloy: the compressive yield strength is 1780 MPa, the compressive fracture strength is 1790 MPa, and the compressive strain is about 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com