A kind of preparation method of lithium borate

A technology of lithium borate and lithium metaborate, applied in borates, chemical instruments and methods, boron compounds, etc., to achieve the effect of no need for post-treatment process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Because lithium oxide is easy to absorb water and deteriorate in the air, in an argon atmosphere glove box, mix lithium metaborate and lithium oxide at a molar ratio of 1:1 and place them in a stainless steel ball mill tank for sealing, with a ball-to-material ratio of 100: 1.

[0030] (2) Milling a ball mill jar containing a mixture of lithium metaborate and lithium oxide at a speed of 500 rpm for 36 hours to obtain a ball mill product.

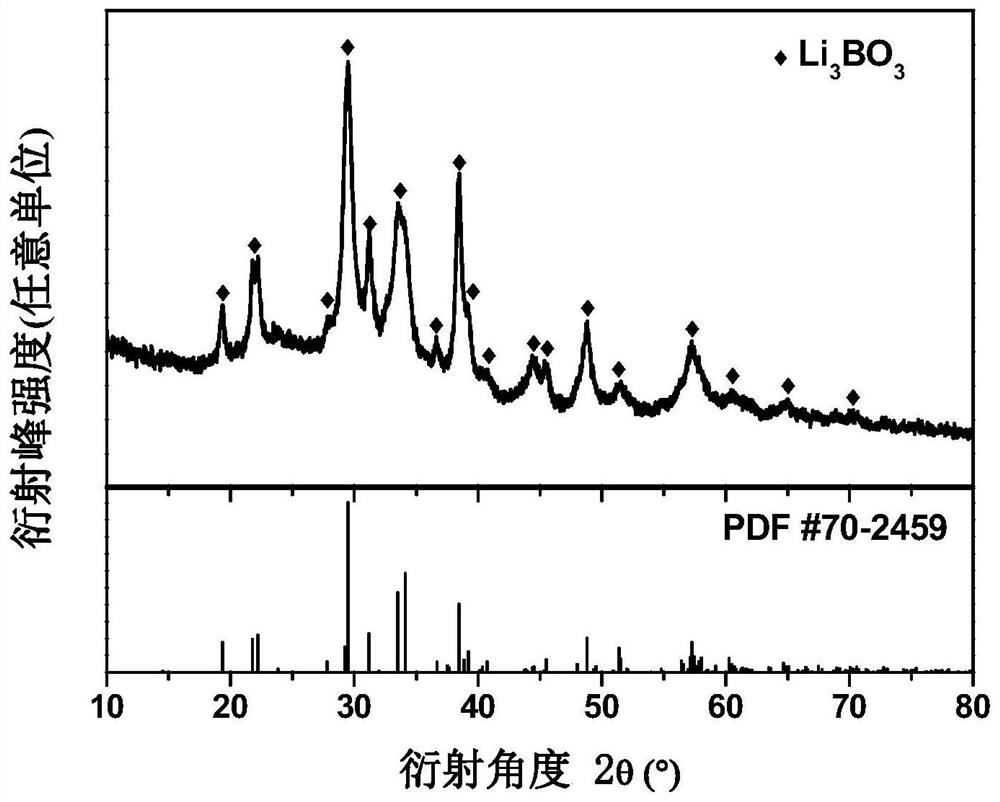

[0031] figure 1 For the X-ray diffraction (XRD) spectrum of the ball mill product prepared in this embodiment, observe the standard PDF card of contrast lithium borate and find that there is no diffraction peak of the initial reactant lithium metaborate and lithium oxide in the ball mill product, only the diffraction peak of lithium borate . It shows that all the initial reactants have reacted to produce pure phase lithium borate.

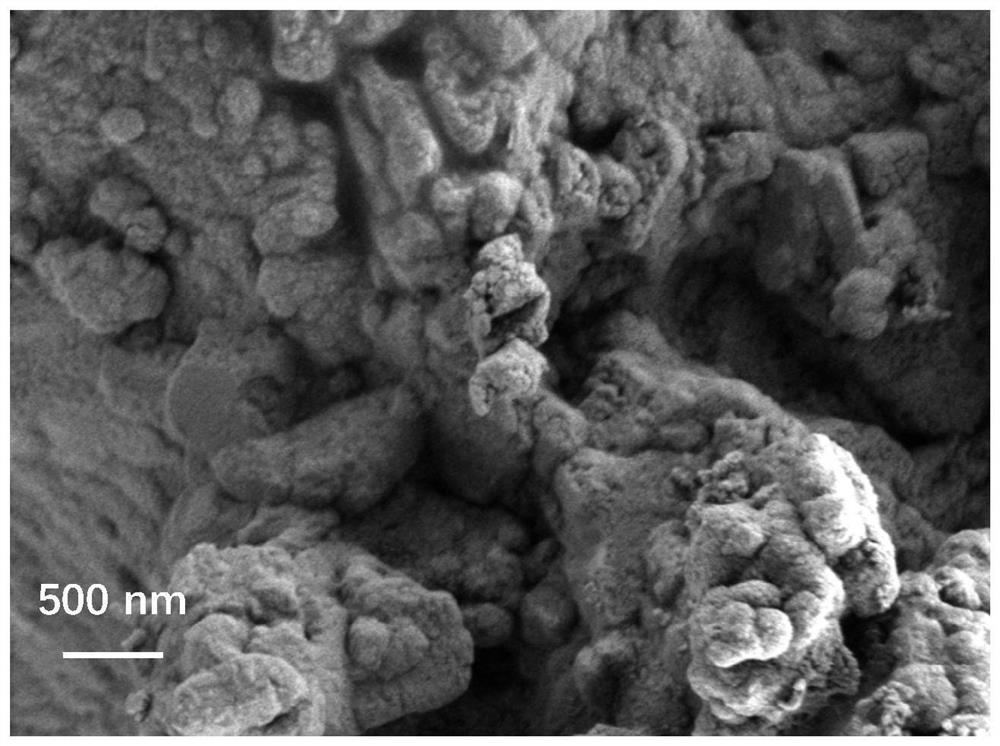

[0032] figure 2 SEM photo of the ball milled product prepared for this example.

Embodiment 2

[0034] The preparation process is the same as that of Example 1, the only difference is that the ball-to-material ratio is adjusted to 200:1.

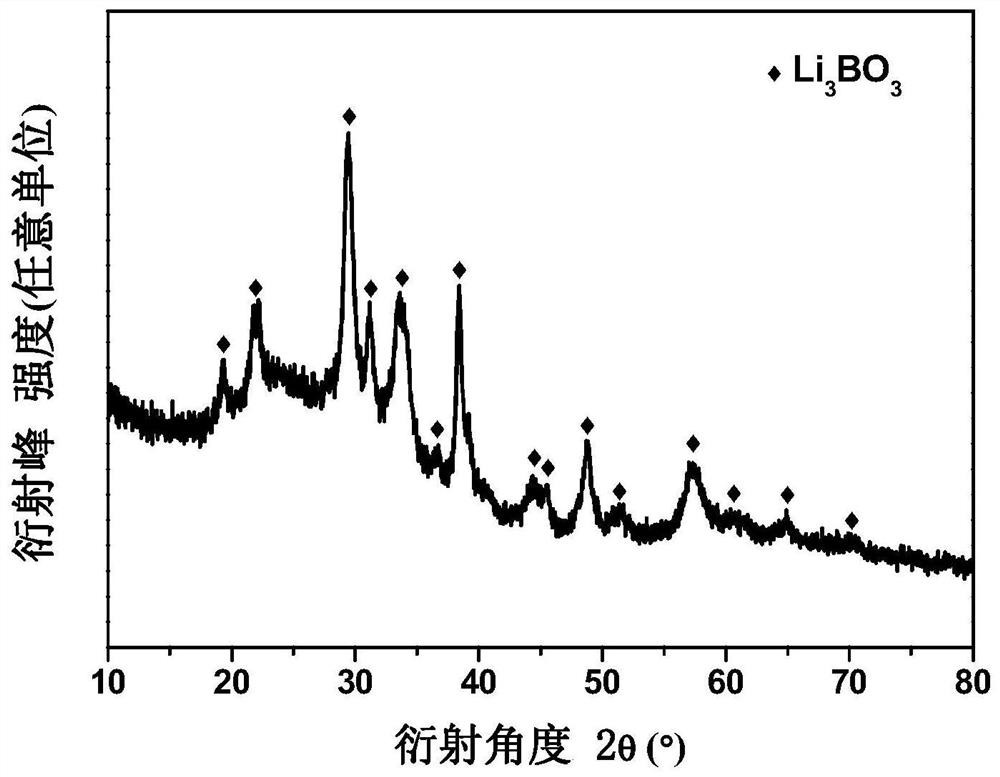

[0035] image 3 The XRD spectrum of the ball milled product prepared for this example. It can be seen from the XRD analysis results that there is only the diffraction peak of lithium borate in the ball milling product, indicating that after the ball milling reaction, lithium metaborate and lithium oxide completely react to form lithium borate. Figure 4 SEM photo of the ball milled product prepared for this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com