Composite membrane for improving permeation selectivity of polyamide nano filtration composite membrane and preparation thereof

A polyamide nanocomposite membrane technology, applied in reverse osmosis, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of improving permeability and selectivity, accelerating self-inhibition, and making the modification process simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The experimental operation steps and conditions are the same as those of the comparative example, the difference is that in the step (1), phthalic anhydride is fully dissolved in acetone, and then the acetone solution containing phthalic anhydride is added to the acetone solution containing 0.15w% homogeneous In n-hexane of trimellitic acid chloride, the solution was ultrasonically treated for 15 minutes, wherein the concentration of phthalic anhydride was 0.02 wt%, and the concentration of acetone was 2 wt%, and this solution was used as the organic phase solution.

Embodiment 2

[0040] The experimental operation steps and conditions are the same as those in Example 1, except that the mass concentration of phthalic anhydride is 0.04 wt%.

Embodiment 3

[0042] The experimental operation steps and conditions are the same as those in Example 1, except that the mass concentration of phthalic anhydride is 0.06 wt%.

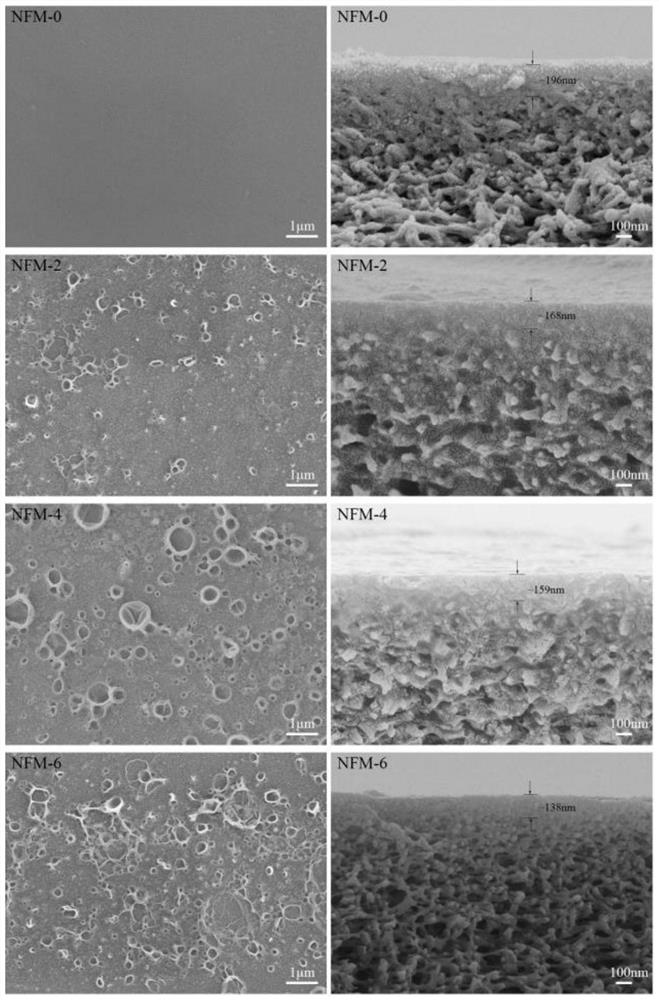

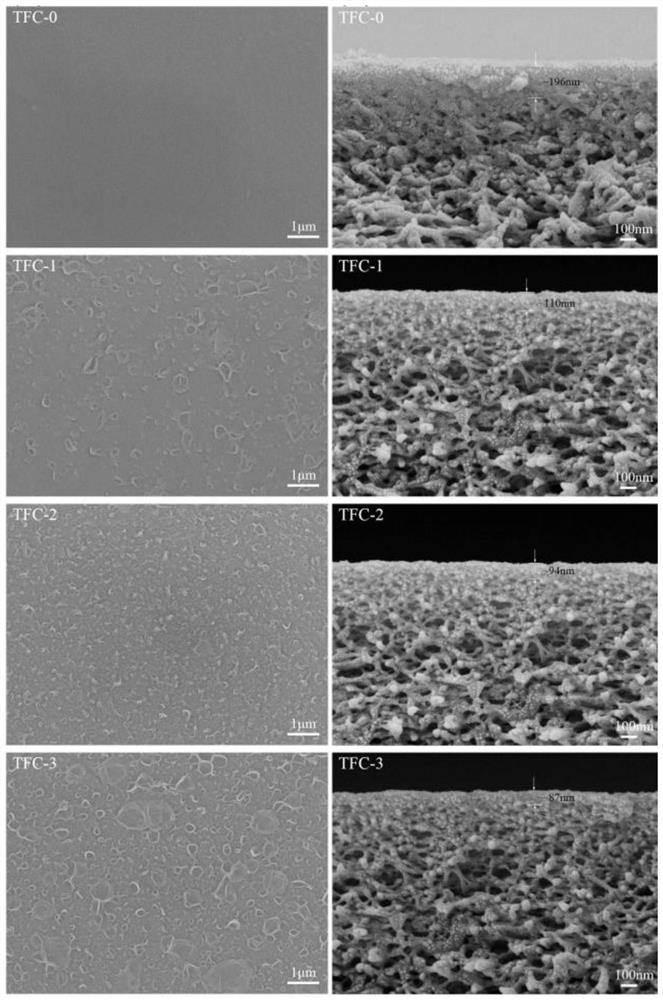

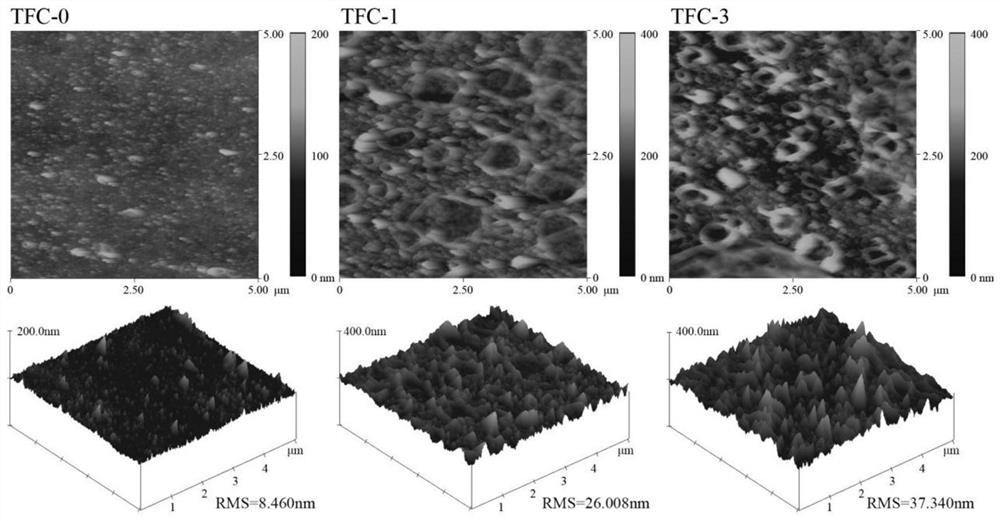

[0043] The scanning electron microscope pictures of the polyamide nanofiltration composite membrane surface and cross-section prepared by comparative examples and Examples 1 to 3 are as follows: figure 1 Shown, among the figure NFMO, NFM2, NFM4, NFM6 correspond to comparative example, embodiment 1, embodiment 2, the polyamide nanofiltration composite membrane that embodiment 3 prepares respectively, figure 1 The left side is the surface morphology of different polyamide nanofiltration composite membranes, figure 1 On the right is the cross-sectional morphology of different polyamide nanofiltration composite membranes. It can be seen that the membranes are intact and free of defects. It can be seen from the figure that with the increase of phthalic anhydride content, new ring-shaped protrusions are formed on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com