Array substrates, display devices, electronic devices

An array substrate and pre-charging technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of affecting the display effect and reducing the aperture ratio of the display panel, and achieve the effect of solving insufficient charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

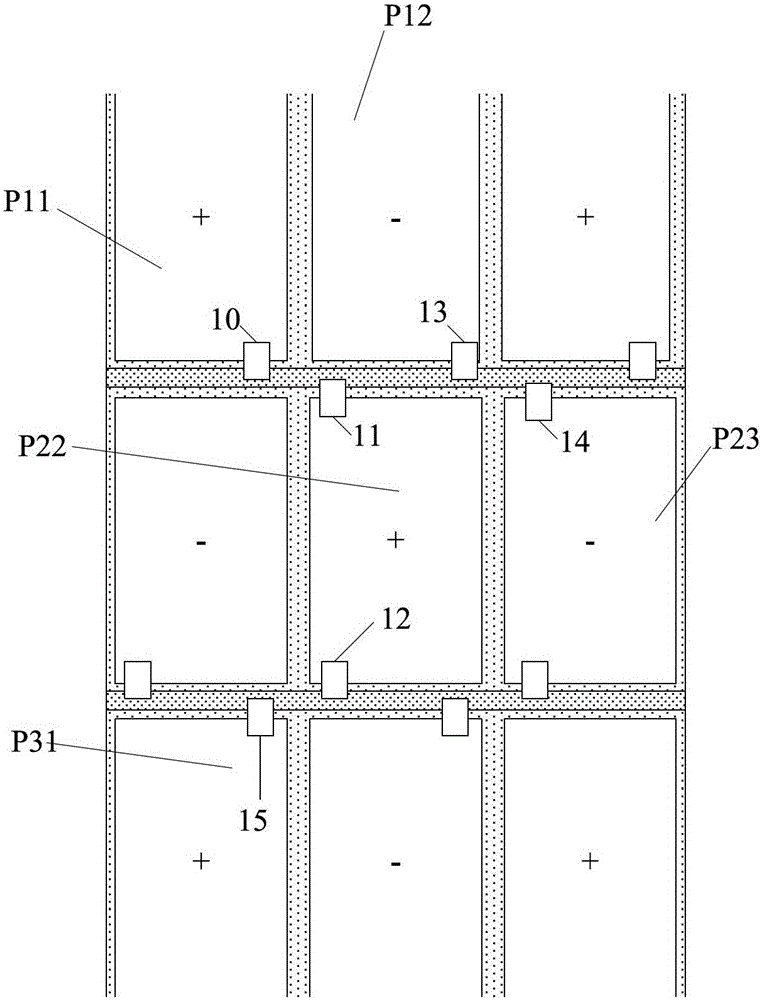

[0027] Such as figure 1 Shown is the pixel structure of the array substrate of this embodiment, from figure 1 It can be seen that in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are opposite; in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are opposite.

[0028] for figure 1 For the sub-pixel P22 in the middle, it includes a charging TFT12 electrically connected to the scanning line corresponding to the sub-pixel in this row and a pixel electrode corresponding to the charging TFT12, wherein the sub-pixel P22 also includes a pre-charging TFT11 and a pre-charging TFT11. Corresponding to the pixel electrode, the pre-charging TFT 11 is electrically connected to the scanning line corresponding to the sub-pixel in the upper row.

[0029] Depend on figure 1 It can be seen that the sub-pixel P11 is located in the upper row of the sub-pixel P22, and has the same polarity as the sub-pixel P22, so ...

Embodiment 2

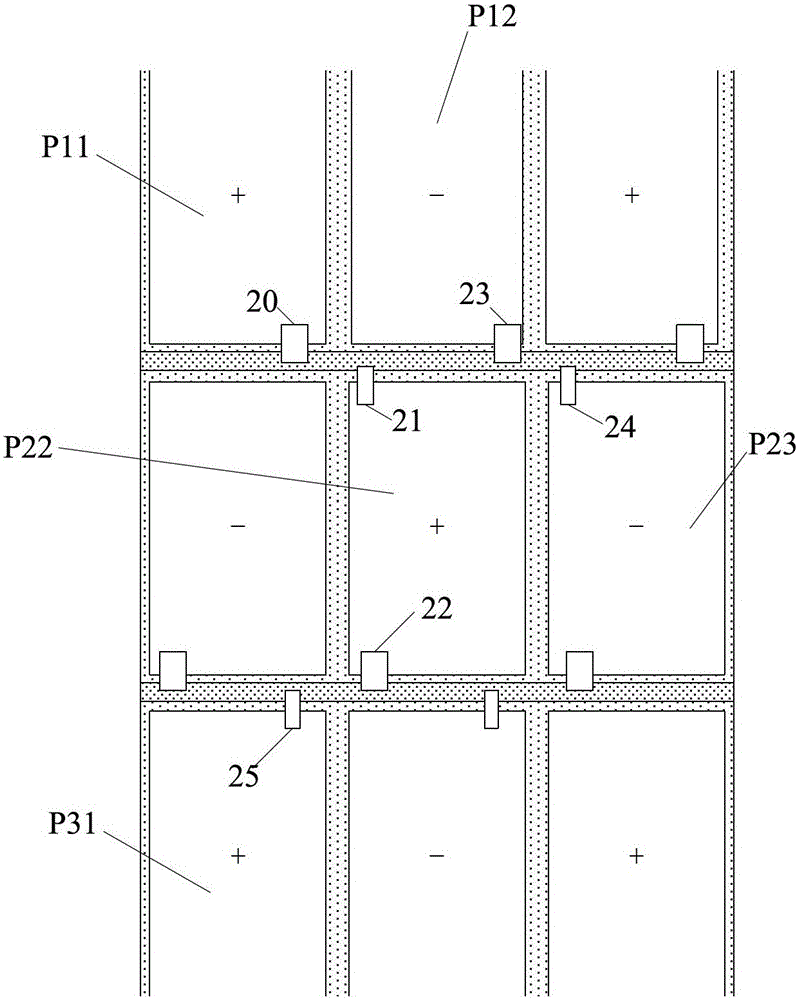

[0036] Such as figure 2 Shown is the pixel structure of the array substrate of this embodiment, from figure 2 It can be seen that in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are opposite; in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are opposite.

[0037] for figure 2 For the sub-pixel P22 in the middle, it includes a charging TFT22 electrically connected to the scanning line corresponding to the sub-pixel in this row and a pixel electrode corresponding to the charging TFT22, wherein the sub-pixel P22 also includes a pre-charging TFT21 and a charging TFT connected to the pre-charging TFT21. Corresponding to the pixel electrode, the pre-charging TFT 21 is electrically connected to the scanning line corresponding to the sub-pixel in the upper row.

[0038] Depend on figure 2It can be seen that the sub-pixel P11 is located in the upper row of the sub-pixel P22, and has the same p...

Embodiment 3

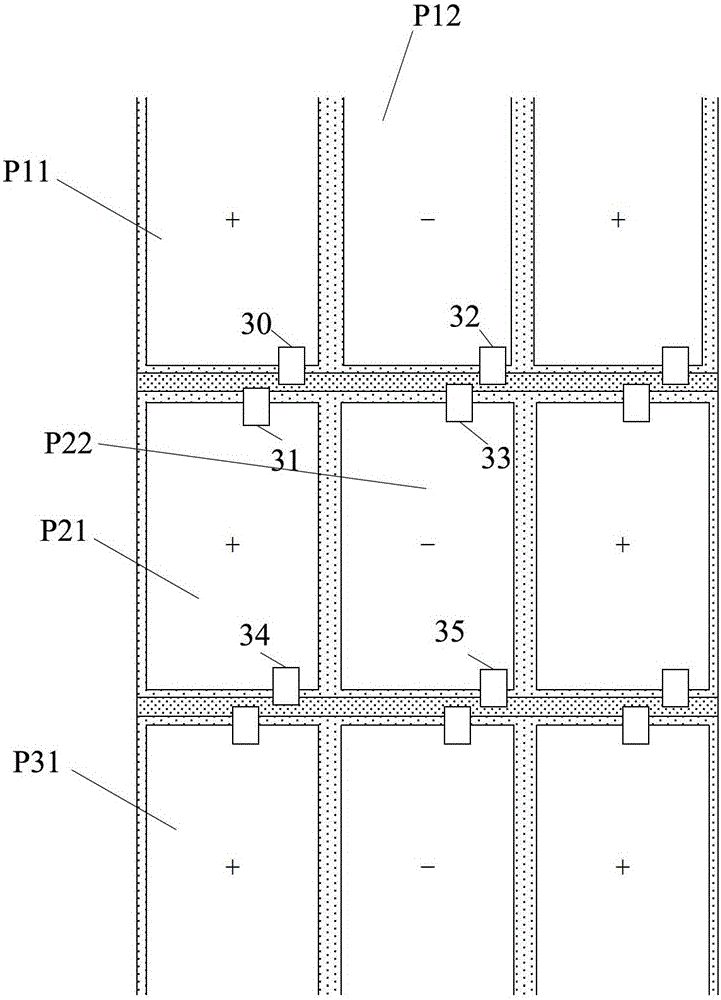

[0045] Such as image 3 Shown is the pixel structure of the array substrate of this embodiment, from image 3 It can be seen that in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are opposite; in the same row of sub-pixels on the array substrate, the polarities of adjacent sub-pixels are the same.

[0046] for image 3 For the sub-pixel P22 in the middle, it includes a charging TFT35 electrically connected to the scanning line corresponding to the sub-pixel in this row and a pixel electrode corresponding to the charging TFT35, wherein the sub-pixel P22 also includes a pre-charging TFT33 and a charging TFT33 Corresponding to the pixel electrode, the pre-charge TFT 33 is electrically connected to the scanning line corresponding to the sub-pixel in the upper row.

[0047] Depend on image 3 It can be seen that the sub-pixel P12 is located in the upper row of the sub-pixel P22, and has the same polarity as the sub-pixel P22, so that wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com