Sand-saving type sand box for manufacturing high-strength sand mould

A high-strength, sand box technology, applied in the direction of mold boxes, manufacturing tools, casting molding equipment, etc., can solve the problems of affecting the quality of sand castings, the weight of the sand box, and the deformation of sand molds, so as to avoid sand deformation or sand leakage pollution The effect of reducing the amount of ground and sand filling and improving the strength and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

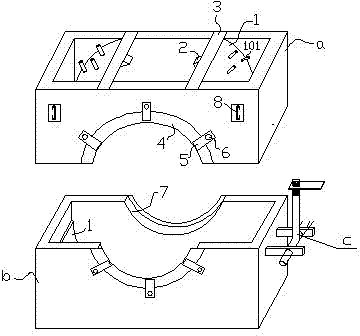

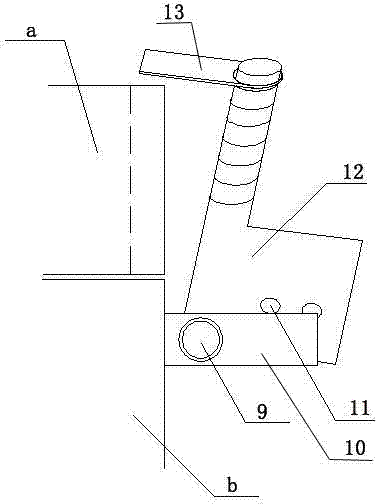

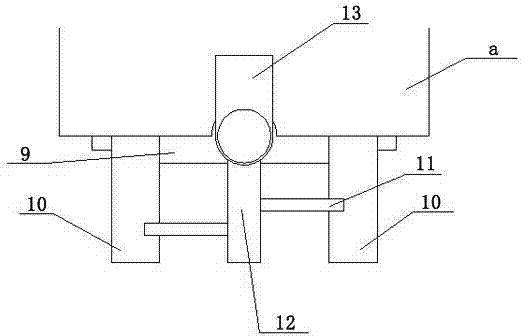

[0020] The specific embodiment of the present invention will be described below in conjunction with the accompanying drawings: a sand-saving sand box for manufacturing high-strength sand molds, including an upper box body a, a lower box body b and a sand box locking mechanism c, and the top of the upper box body a The bottom port of the lower box b is open, the sides of the upper box a and the lower box b are provided with core openings 7, and the upper box a and the lower box b are equipped with arc-shaped plates 1, arc-shaped plates The concave surface of 1 faces the center of the box body, and the two sides of the arc-shaped plate 1 are fixedly connected with the inner walls of both sides of the box body, and one end of the arc-shaped plate 1 is flush with the port of the box body, and is connected with the connection plate 3, The two ends of the two sides are respectively fixedly connected with the side walls on both sides of the box body. Strip keels 2 are provided on the ...

Embodiment 1

[0030] A sand-saving sand box for making high-strength sand molds, including an upper box body a, a lower box body b, and a sand box locking mechanism c. There are multiple sets of sand box locking mechanisms c, all of which are arranged on the side of the sand box , the top of the upper box a and the bottom port of the lower box b are open, the sides of the upper box a and the lower box b are provided with core openings 7, and the upper box a and the lower box b are equipped with arc Plate 1, the concave surface of the arc-shaped plate 1 faces the center of the box body, the two sides of the arc-shaped plate 1 are fixedly connected with the inner walls of both sides of the box body, and one end of the arc-shaped plate 1 is flush with the port of the box body and connected with the connecting plate 3 connection, the two ends of the connecting plate 3 are respectively fixedly connected with the side walls on both sides of the box body, strip keels 2 are provided on the concave s...

Embodiment 2

[0037] A sand-saving sand box for manufacturing high-strength sand molds, including an upper box body a, a lower box body b, and a sand box locking mechanism c. There are four sets of sand box locking mechanisms c, all of which are arranged on four sides of the sand box On one side, the top of the upper box a and the bottom port of the lower box b are open, the sides of the upper box a and the lower box b are provided with core openings 7, and the upper box a and the lower box b are provided with There is an arc-shaped plate 1, the concave surface of the arc-shaped plate 1 faces the center of the box body, the two sides of the arc-shaped plate 1 are fixedly connected with the inner walls of both sides of the box body, and one end of the arc-shaped plate 1 is flush with the port of the box body, and Connected with the connecting plate 3, the two ends of the connecting plate 3 are respectively fixedly connected with the side walls on both sides of the box, the concave surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap