Impeller structure of wave-energy power generation conversion device

A conversion device and wave energy technology, applied in the field of impeller structure of wave energy power conversion device, can solve the problems of poor rotation direction consistency, low conversion rate, etc., to ensure stability, improve conversion efficiency, and increase stress area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

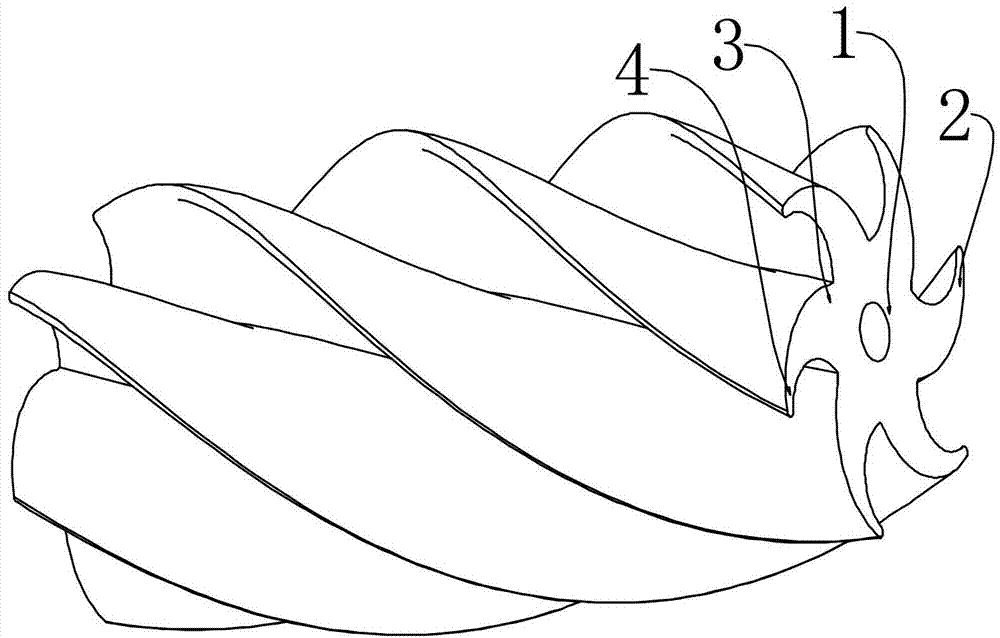

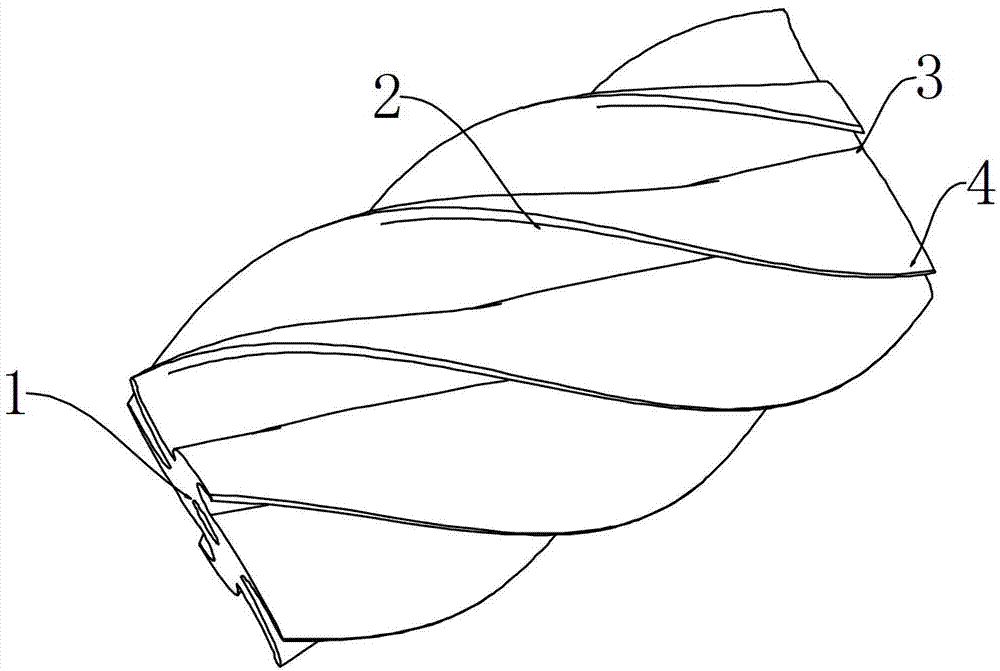

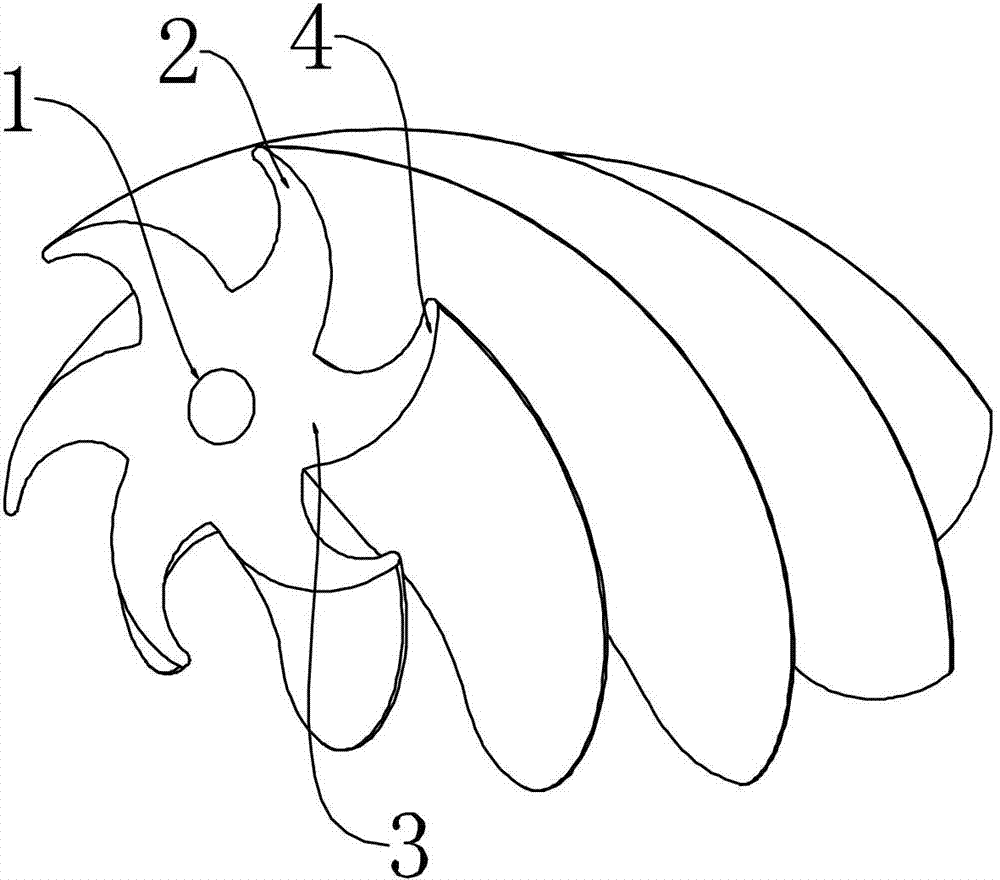

[0026] Such as figure 1 As shown, the impeller structure of a wave energy power conversion device in the present invention includes an impeller body 1 and a plurality of blades 2 evenly distributed on the impeller body.

[0027] Each of the blades 2 is helical, so that the area of the blades is as large as possible in the same size range, so that the force-bearing area of the impeller increases in waves, which can overcome the current disadvantages of small force-bearing area and low efficiency of the impeller. Make effective improvements. The structure of each of the blades 2 is the same, so as to facilitate processing and bear force in waves.

[0028] Such as figure 1 and Figure 4 As shown, the thickness of the blade in each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com