One-step-molded glass-lined pipe bundle condenser jacket

A condenser and glass-lined technology, which is applied in the field of glass-lined tube condenser jackets, can solve problems such as easy loosening during disassembly, reduced service life, and weak compression resistance, so as to reduce left and right shaking, increase service life, and increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

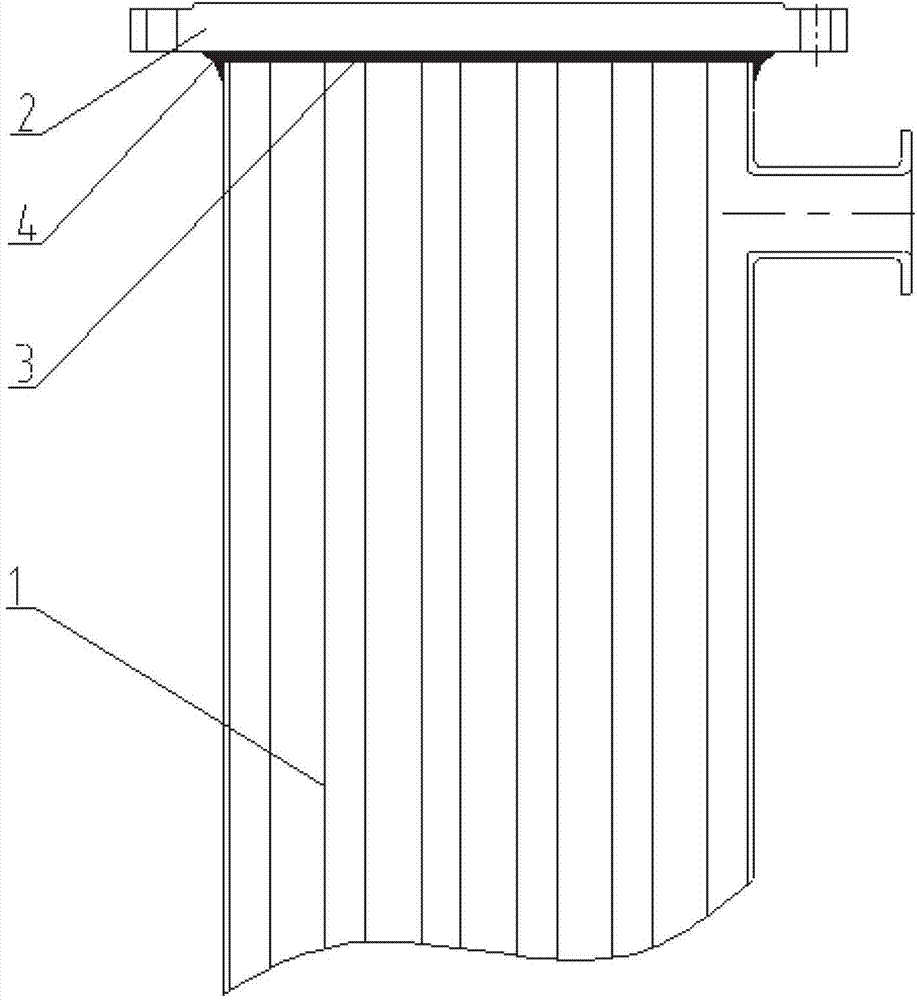

[0011] Such as figure 1 The one-time formed glass-lined tube condenser jacket mainly includes a tube cover 1 and a head cover 2. The tube cover 1 is inserted into the head cover 2, and the welding strip 3 is used to connect the tube cover 1 and the cover in the contact gap. The headgear 2 is fixed together, and a triangular welding block 4 is provided at the side contact of the tube sleeve 1 and the headgear 2 for welding, and the welding strip 3 is formed by one-time welding.

[0012] The basic principles, main features and advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments, and what described in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com