Unit circuit board replacement method of circuit board and product sheet of circuit board

A circuit board and circuit board technology, which is applied in the field of unit circuit board replacement of circuit boards and finished products of circuit boards, can solve problems such as rising cost of circuit boards, and achieve the effects of improving productivity, suppressing flow, and improving support stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

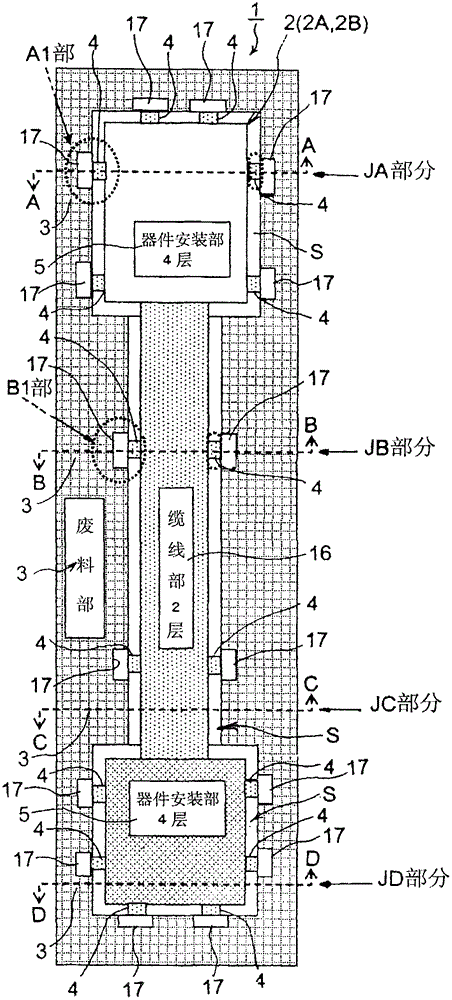

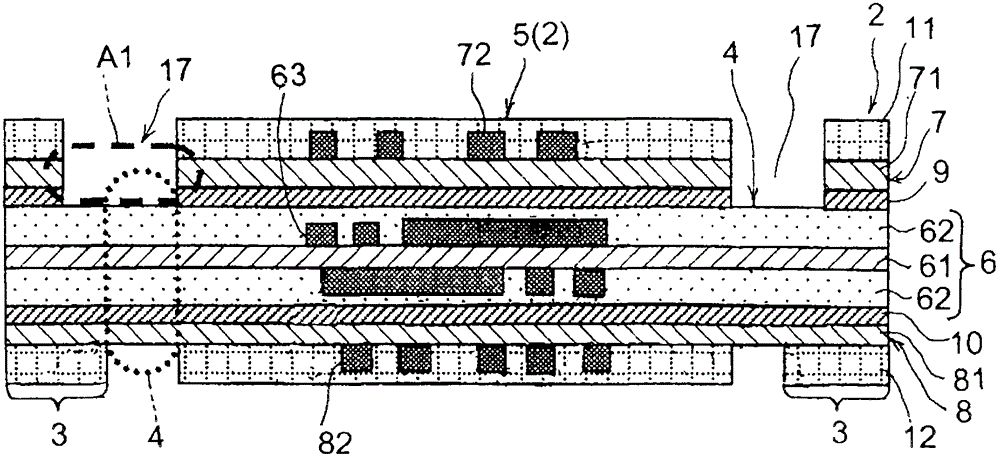

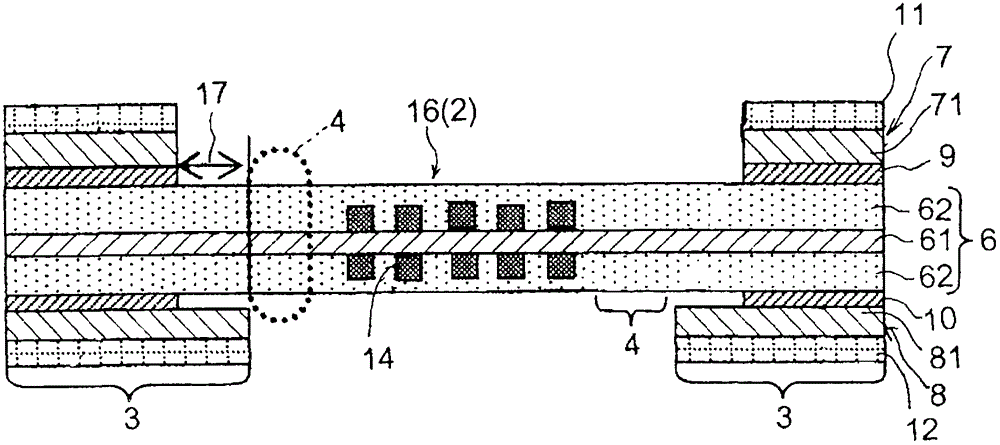

[0100] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 It is a plan view showing the product sheet 1 of the circuit board of the laminated board of this embodiment. The product sheet 1 is composed of a unit circuit board 2 of a multilayer structure as a product forming part; a shell-shaped waste part 3 provided on the outer periphery of the unit circuit board 2; A plurality of joint parts 4, 4 ... constituted by connecting a plurality of parts of the body. On the component mounting portions 5, 5 provided oppositely on the unit circuit board 2, electronic components and the like are automatically mounted by an inserter or the like.

[0101] Specifically, the product shape of the unit circuit board 2 is formed by punching out predetermined parts of the product shape other than the joint portions 4 , 4 . . . of the product sheet 1 . The punched part S generated at this time is used as a boundary area, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com