Bionic core moldboard type sowing boot

A technology of sowing openers and bionic cores, which is applied in the direction of excavation/covering trenches, planting methods, applications, etc., can solve problems such as increased resistance, reduce working resistance, reduce soil adhesion, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

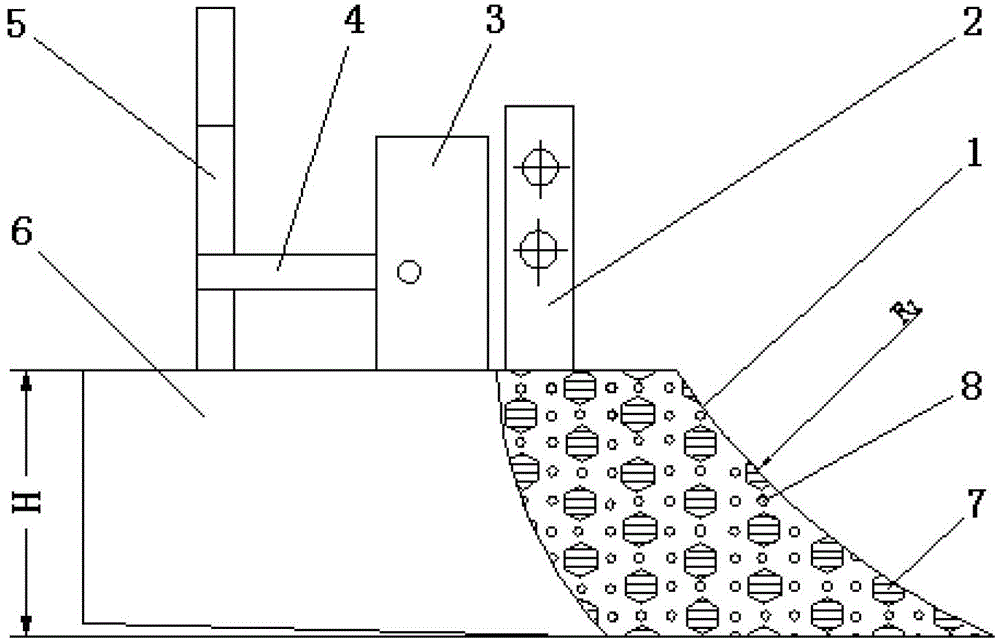

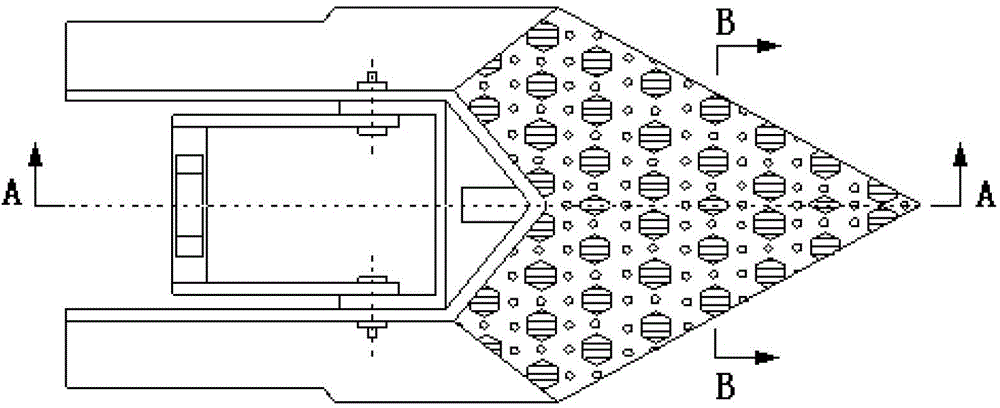

[0023] Such as figure 1 , The vertical side length of the coreshare type sowing opener is H=80-140mm, the horizontal side length is L=130-170mm, the radius of curvature of the ridge line R1=250-350mm, and the surface shape of the scale-shaped geometric structure 7 is a symmetrical hexagon Structure: side length L1=1~20mm, L2=1~30mm, inner angle α 1 =120~130°, interior angle α 2 =100-110°, convex-hull geometric structure 8, top circle radius R=1-4mm; bottom circle radius R+r=5-10mm; convex-hull height h=1-4mm. The distance L between the centers of the two bionic structures, the scale-shaped geometric structure 7 and the convex-hull geometric structure 8, is 5-25mm.

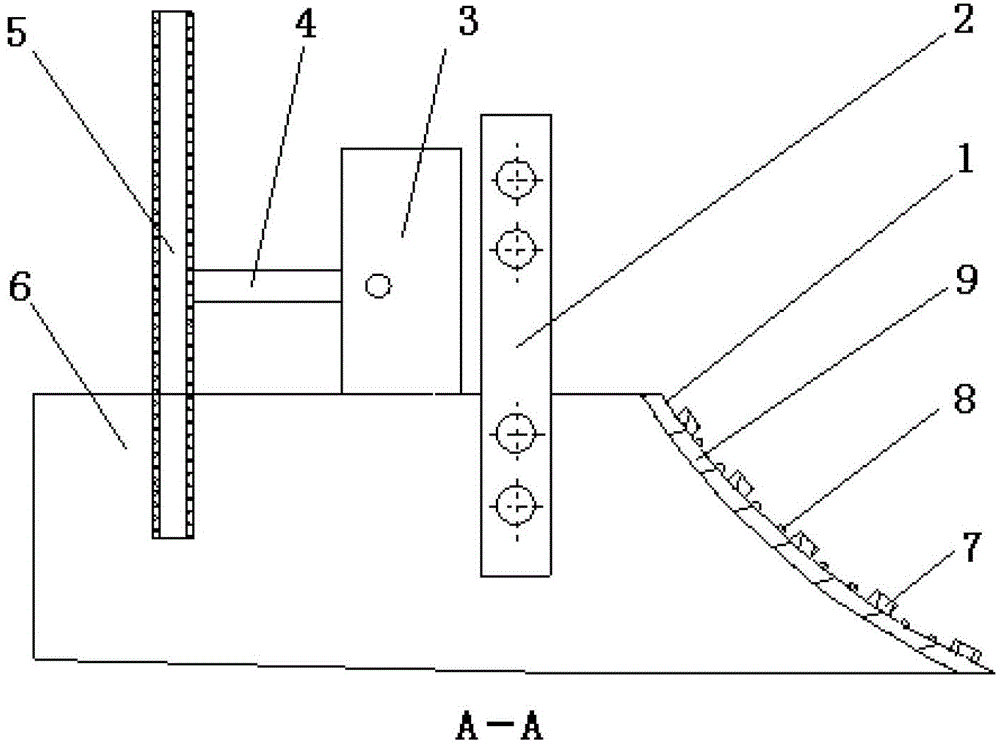

[0024] Such as Figure 5 , the thickness of the conventional substrate 9 is D=2-4 mm, the height H1 of the scale-shaped geometric structure 7 is 1-4 mm, and the side inclination angle δ=55°-70°. The surface bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com