Side-slit drip irrigation belt

A drip irrigation belt and edge seam technology, applied in the direction of spray device, spray device, etc., can solve the problems of short laying distance, insufficient, wet area formation, etc., and achieve the effect of increasing laying length, improving utilization rate and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

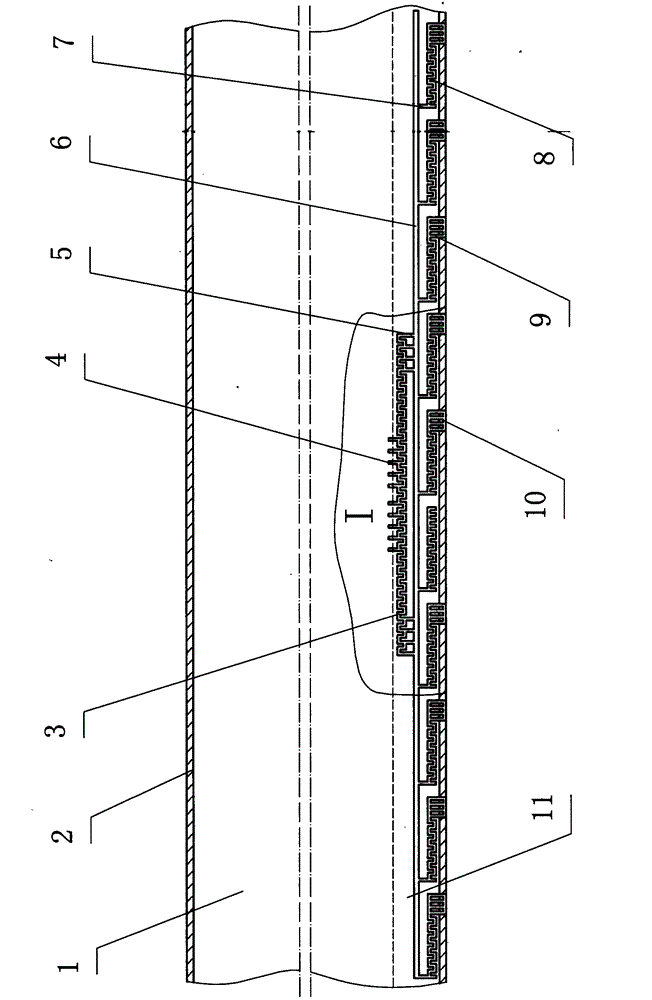

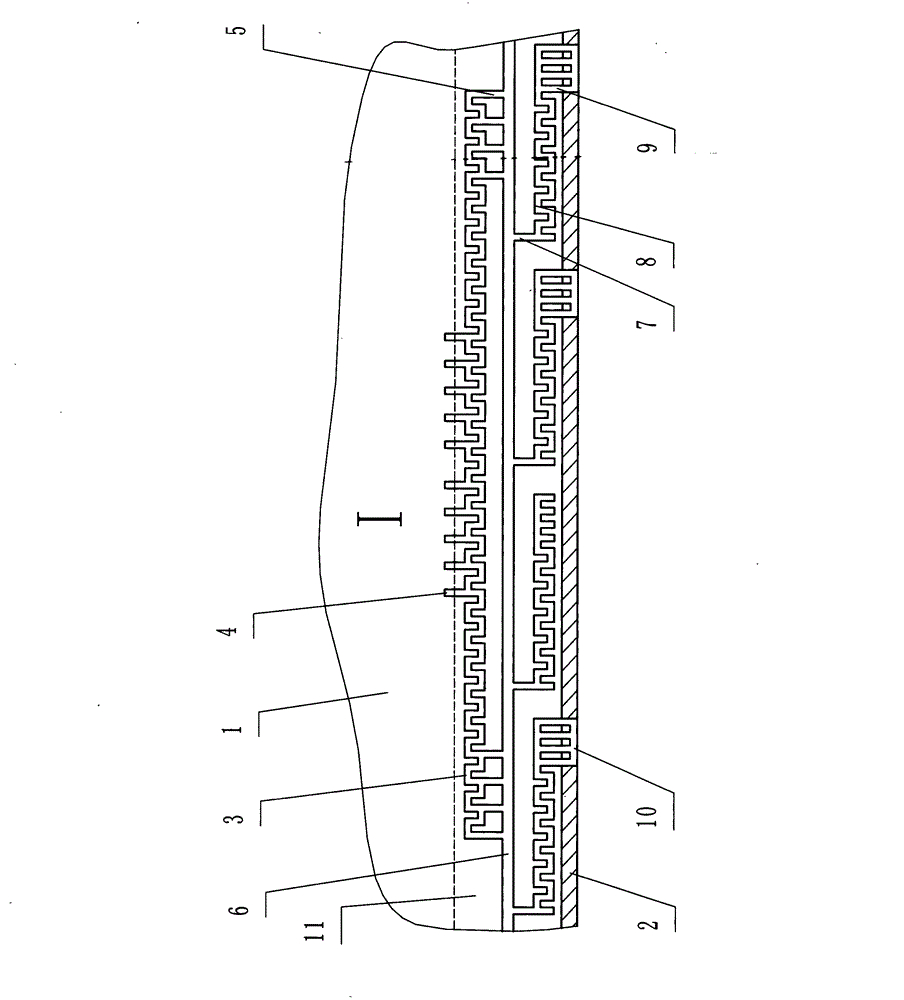

[0017] Embodiment 1: with reference to attached Figure 1~2 , comprising a drip irrigation tape body 2, a drip irrigation tape inner cavity 1 and a drip irrigation tape edge seam 10, the drip irrigation tape edge seam 10 is provided with a main channel 3, a secondary flow channel 8 and a buffer flow channel 6, and the main channel 3 is located at The side seam 10 of the drip irrigation belt is on the side of the inner chamber 1 of the drip irrigation belt, and the auxiliary flow channel 8 is arranged on the side of the side seam 10 of the drip irrigation belt near the side of the body 1 of the drip irrigation belt. Between the channel 3 and the secondary channel 8, the main channel 3 is provided with a main channel inlet 4 and a main channel outlet 5, the main channel inlet 4 communicates with the inner cavity 1 of the drip irrigation belt, and the main channel outlet 5 communicates with the buffer channel 6 , The secondary channel 8 is provided with a secondary channel inlet ...

Embodiment 2

[0018] Embodiment 2: Compared with Embodiment 1, the difference is that: the main channel 3 is in the shape of sawtooth "concave-convex" and is arranged continuously; the secondary channel 8 is in the shape of sawtooth "concave-convex" and is continuously arranged; There are six inlets 4, at least two outlets 5 of the main channel, two outlets 9 of the secondary channel, and one main channel unit and one auxiliary channel unit.

Embodiment 3

[0019] Embodiment 3: Compared with Embodiment 1, the difference is that: there are twelve main channel inlets 4, at least three main channel outlets 5, three secondary channel outlets 9, one main channel unit and It consists of twelve sub-runner units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com