Single-ellipsoidal double-parabola streamlined irrigation emitter plug and mounting method thereof

A streamlined, irrigator technology, applied in watering devices, botanical equipment and methods, gardening, etc., can solve problems such as large head loss, and achieve the effects of increasing laying length, reducing shape resistance, and increasing conveying distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

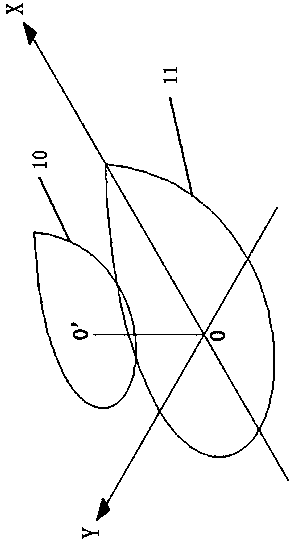

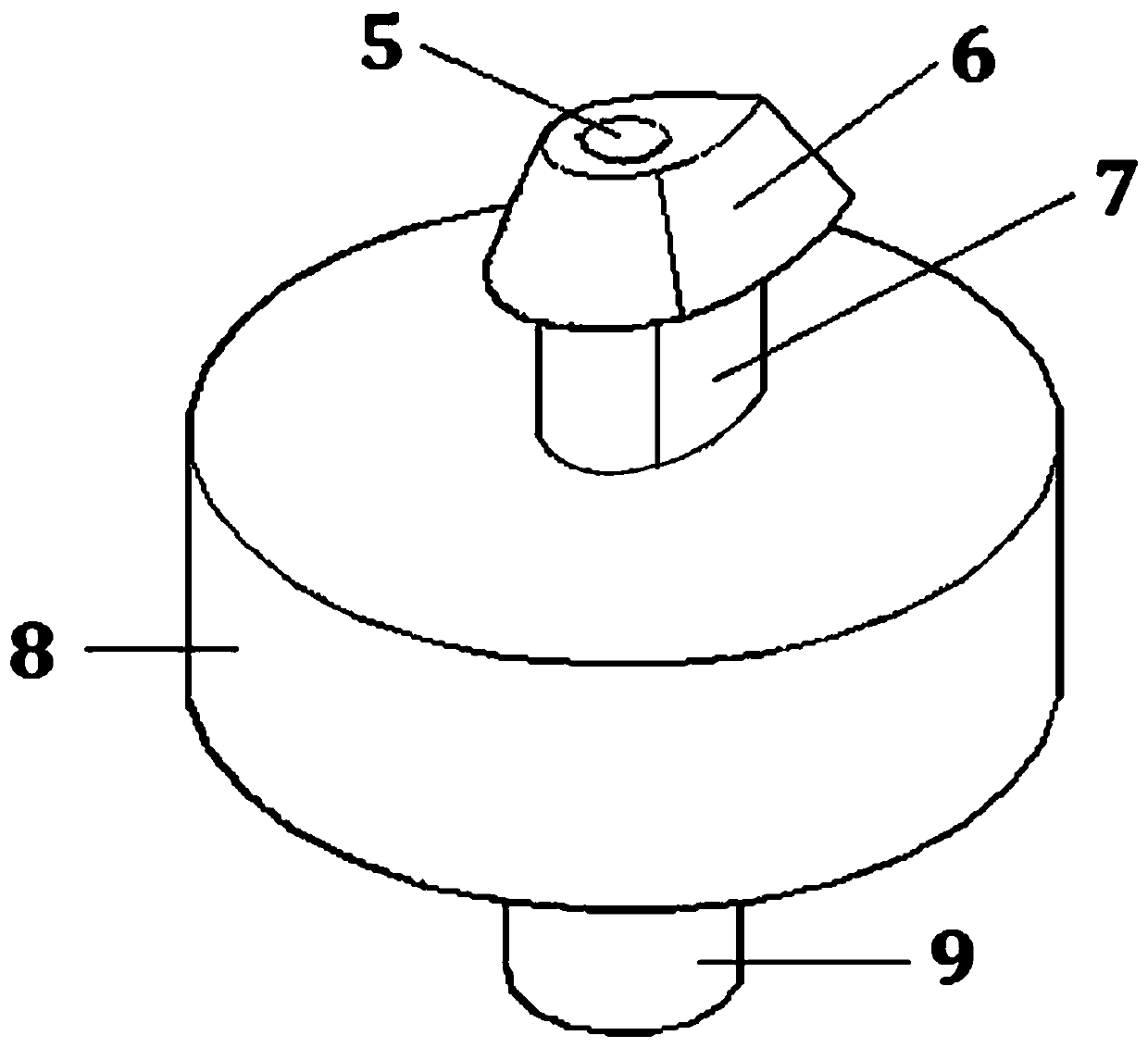

[0076] like image 3 As shown, a single ellipse double-throwing streamline emitter plug includes a plug inverted cone 6, the upper end of the plug inverted cone 6 is provided with a plug water inlet 5, and the lower surface of the plug inverted cone 6 is sequentially connected with the plug cone neck 7, from top to bottom. The dripper cavity 8 and the dripper outlet pipe 9 are connected, the cross-sectional contour line of the plug inverted cone 6 is a single ellipse double-throw streamlined curve, and the second single-ellipse double-throw streamlined curve 10 on the upper end surface encloses the smallest plane space area , the plane space area surrounded by the first single ellipse double throw streamlined curve 11 on its lower end face is the largest; The area of the plane space enclosed by the elliptic double parabolic streamlined curves is the same.

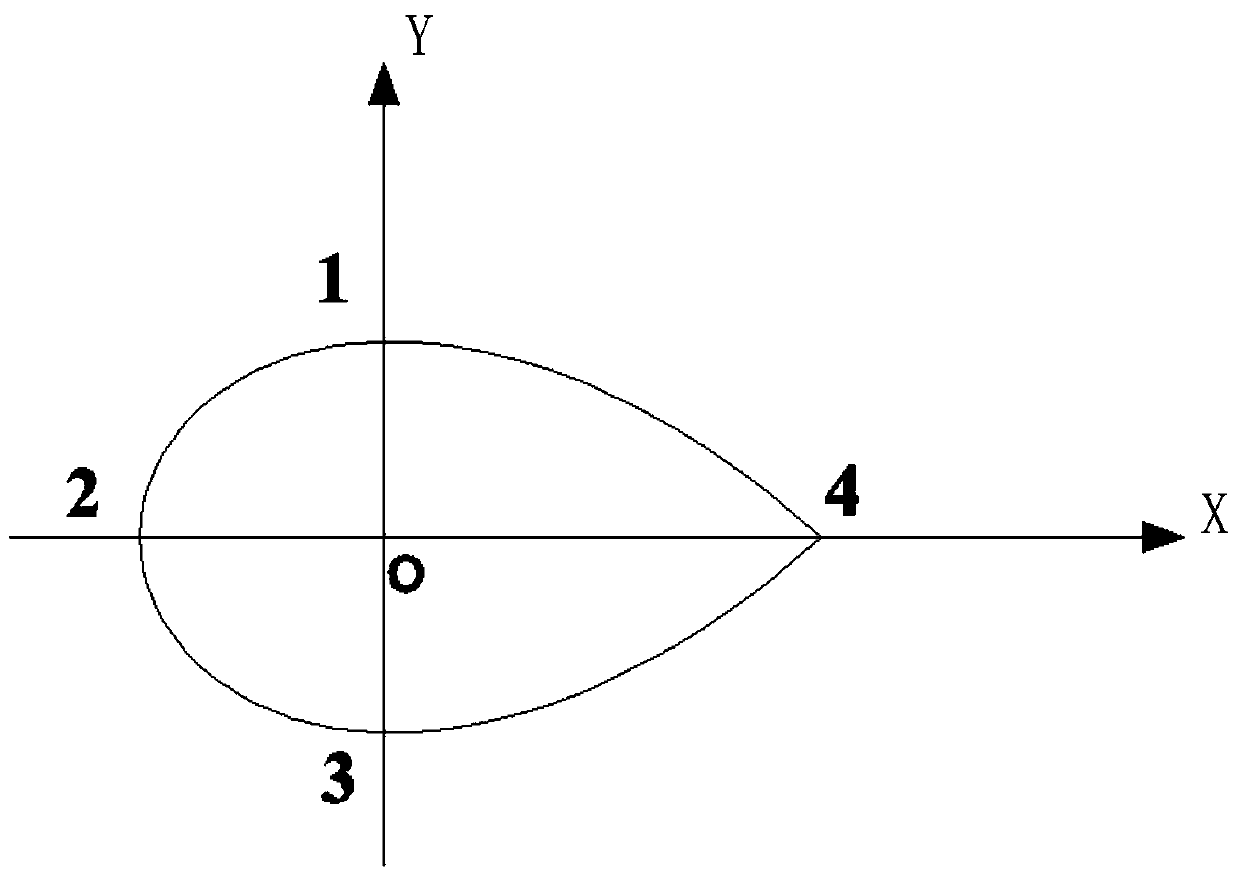

[0077] like figure 2 Shown:

[0078] Plug inverted cone 6 is obtained through the following steps:

[0079] Step 1...

Embodiment 2

[0100] A method for installing the above-mentioned single-ellipse double-throw streamlined emitter plug, the first single-ellipse double-throw streamlined curve 11 of the plug inverted cone 6 of the emitter plug is placed in front along the curve 1-2-3 of the upstream section, and the outflow section The curve 1-4-3 is aligned with the punched hole and inserted into the capillary in the rear direction, and then the inserted emitter plug is pulled back until the lower end surface of the plug inverted cone 6 is close to the inner wall of the capillary to ensure that the plug and the capillary fit tightly , to prevent water leakage during irrigation.

Embodiment 3

[0102] The drip irrigation pipe composed of the conical emitter emitter plug and the single ellipse double throw streamlined emitter plug is simulated to observe the resistance of the two emitter plugs:

[0103] Set a 1m-long capillary, and insert three single-ellipse, double-throw streamlined emitter plugs into the capillary with a distance of 0.2m. As a control, a 1m long capillary was also taken, and three conical emitter plugs were inserted into it to simulate the total head loss of the capillary. The head loss along the capillary is calculated by Darcy's formula, and the local head loss is obtained by subtracting the head loss along the capillary from the total head. According to the simulation results, the single-ellipse double-throwing streamlined emitter plug can effectively reduce the local resistance of the emitter, and the drag reduction ratio is 15.1%-27.5%. (This ratio shows that the single-ellipse double-throw streamlined dripper can effectively reduce the local...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com