Patents

Literature

54results about How to "Extend the conveying distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

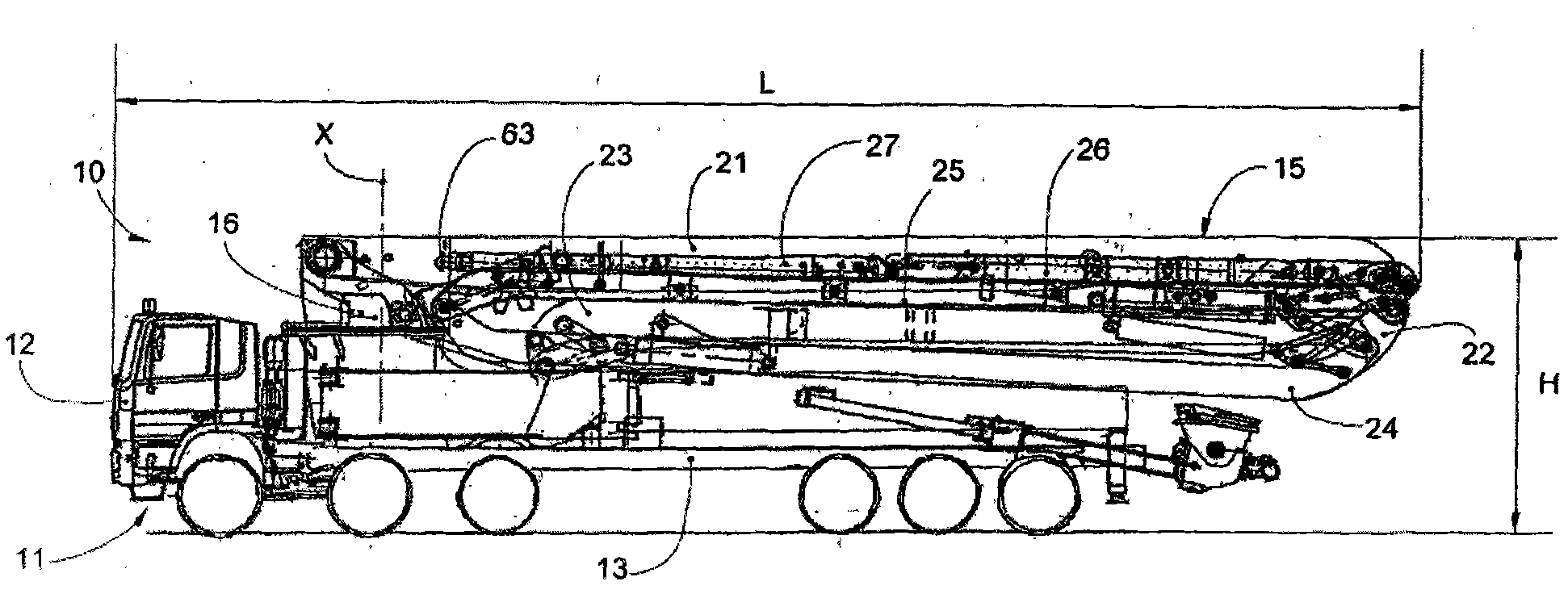

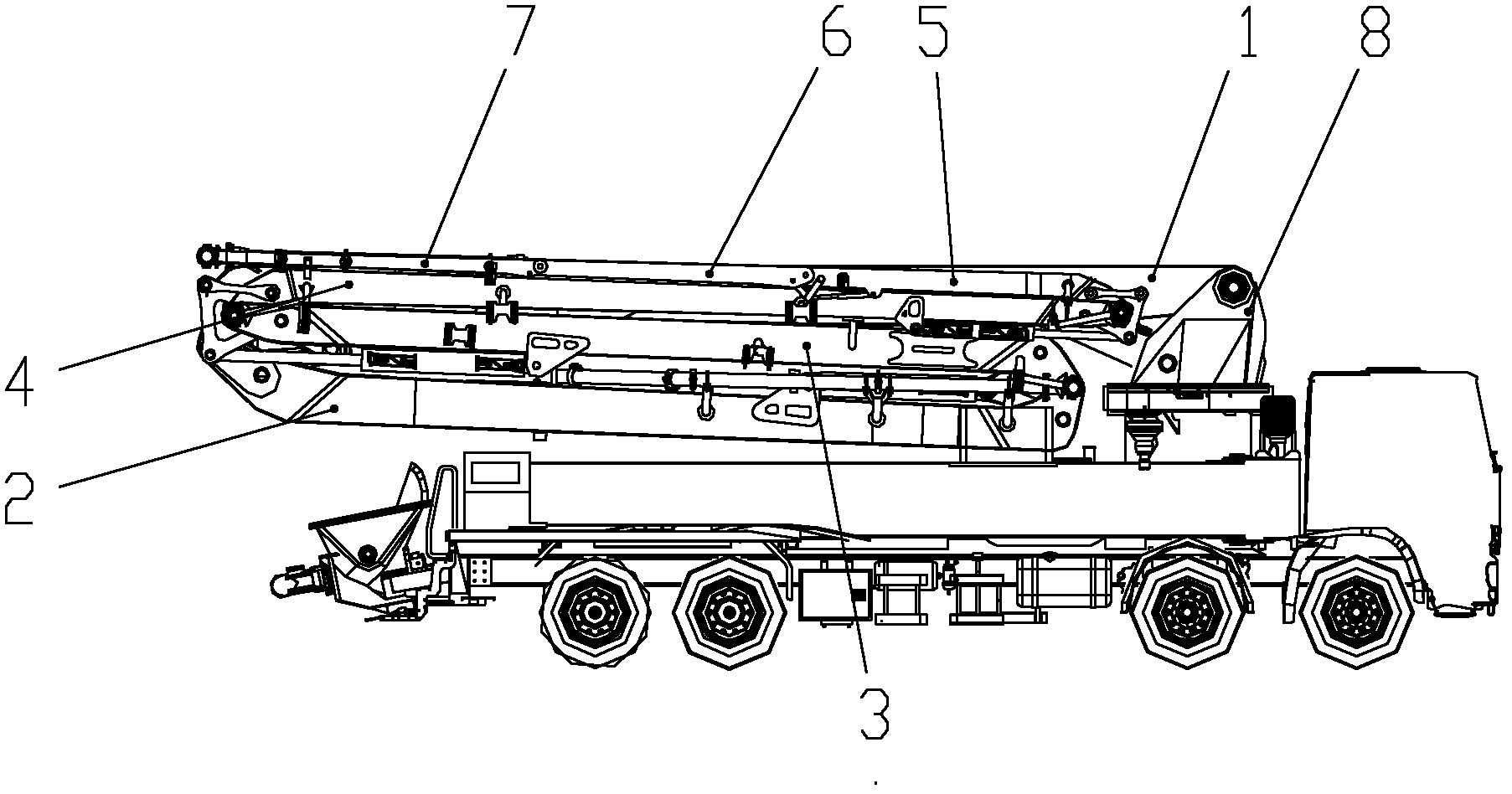

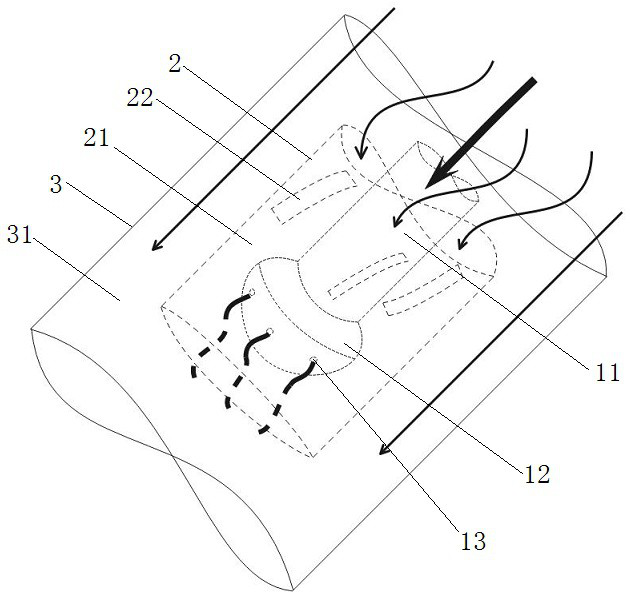

Arm support of concrete pump truck and concrete pump truck

ActiveCN102359278AExtend the conveying distanceBuilding material handlingMechanical engineeringConcrete pump

The invention provides an arm support of a concrete pump truck. The arm support has a folding state and an unfolding state and comprises at least six arm sections which are sequentially hinged with one another, wherein in the folding state, a first arm section and a second arm section are positioned on a first longitudinal surface; a fourth arm section, a fifth arm section and a sixth arm sectionare positioned on a second longitudinal surface; the first longitudinal surface and the second longitudinal surface are mutually parallel and are separated from each other; a third arm section is extended between the first longitudinal surface and the second longitudinal surface; the first, second, third, fourth and fifth section arms are folded towards a first direction; and the sixth arm section is folded to the fifth arm section towards a second direction opposite to the first direction. The invention also provides the concrete pump truck with the arm support. According to the technical scheme, the conveying distance of concrete can be increased as far as possible when the arm support is unfolded under the condition that the integral size of the pump truck in the folding state is not increased basically.

Owner:ZOOMLION HEAVY IND CO LTD

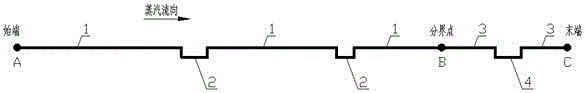

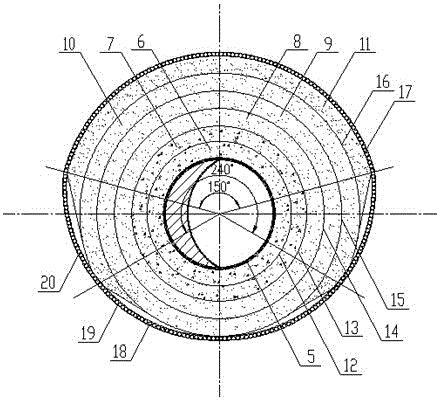

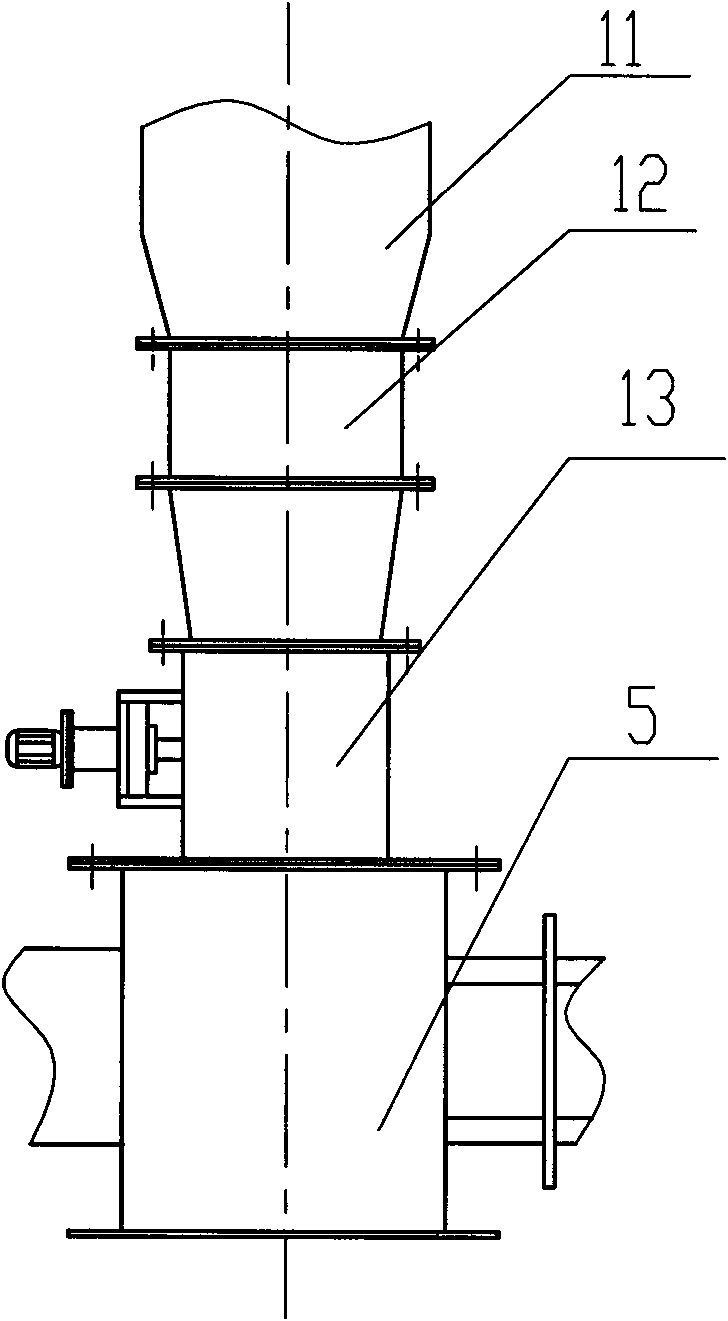

Ultra-distance steam conveying pipeline

ActiveCN105823108AExtend the conveying distanceSmall pressure dropLighting and heating apparatusSteam central heatingEngineeringTemperature drop

The invention relates to an ultra-distance steam conveying pipeline. The ultra-distance steam conveying pipeline comprises a superheated steam section and a superheated / saturated steam section. The superheated steam section and the superheated / saturated steam section each comprise an overhead steam pipeline and a buried steam pipeline. The superheated steam section comprises a steam pipeline body, multiple insulating layers, multiple reflecting layers, a nanometer air cushion thermal insulating layer, a damp-proof layer and a protective layer (or an air layer or an outer steel pipe). The superheated / saturated steam section comprises a steam pipeline body, a heat storage layer, multiple insulating layers, multiple reflecting layers, a nanometer air cushion thermal insulating layer, a damp-proof layer and a protective layer (or an air layer and an outer steel pipe). The ultra-distance steam conveying pipeline further comprises a fixed seat matched with the overhead steam pipeline. The steam pipe conveying distance can be effectively increased, and the conveying distance ranges from 40 km to 50 km. The pressure drop, temperature drop and quality losses in the conveying process are reduced, and the quality losses are only 0-1%. Thus, the steam production cost is reduced, energy is saved, and waste gas emissions are reduced.

Owner:南京苏夏设计集团股份有限公司

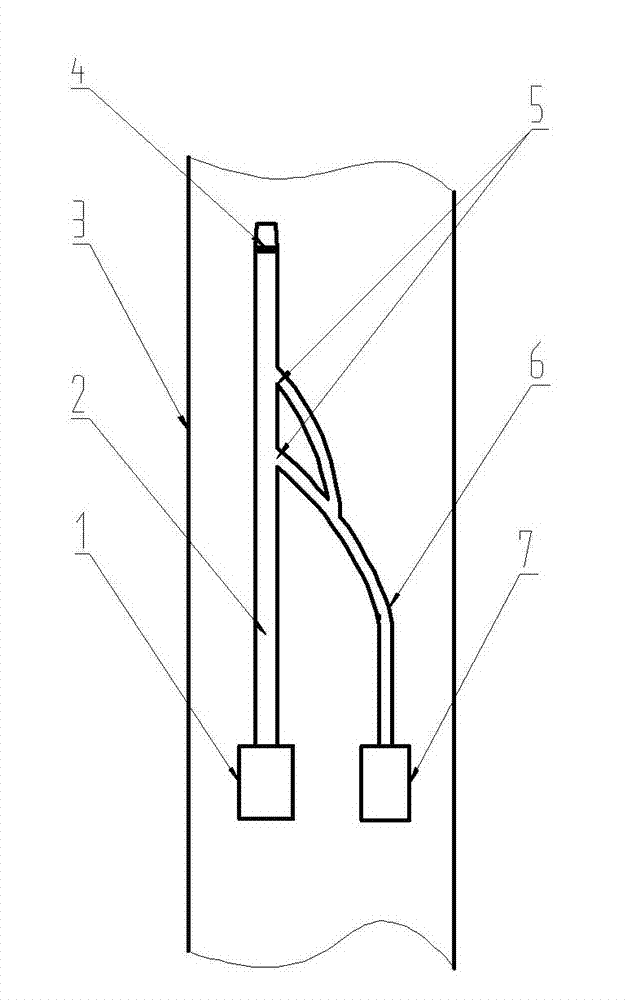

Mining method for jetting concrete in wet type

ActiveCN102733823AReduce cloggingAvoid restrictionsUnderground chambersTunnel liningShotcreteCement slurry

The invention relates to a mining method for jetting concrete in a wet type; a method comprises the following steps: preparing cement slurry; stirring gravel mixing material; starting air source to input high pressure air to a gravel mixing material transport pipeline in a jetting procedure; and inputting the cement slurry to a cement slurry transport pipeline through transport equipment; after jetting the cement slurry by a nozzle, adding the gravel mixing material to a jetting machine; under the action of the high pressure air, mixing and stirring the cement slurry and the gravel mixing material; finally, jetting the concrete from the nozzle. According to the invention, the method depends on current jetting equipment; a transport distance (larger than or equal to 60m) of jet concrete is can be increased greatly on a condition of ensuring invariable wet-type concrete jetting advantages; simultaneously, the method effectively avoids problems that large-scale stirring is used hardly and concrete transport equipment is limited under a coal well; production efficiency and jetting quality are improved greatly; in addition, powder dust concentration near the jetting machine is less than or equal to 10mg / m<3>.

Owner:河南省煤科院科明机电设备有限公司

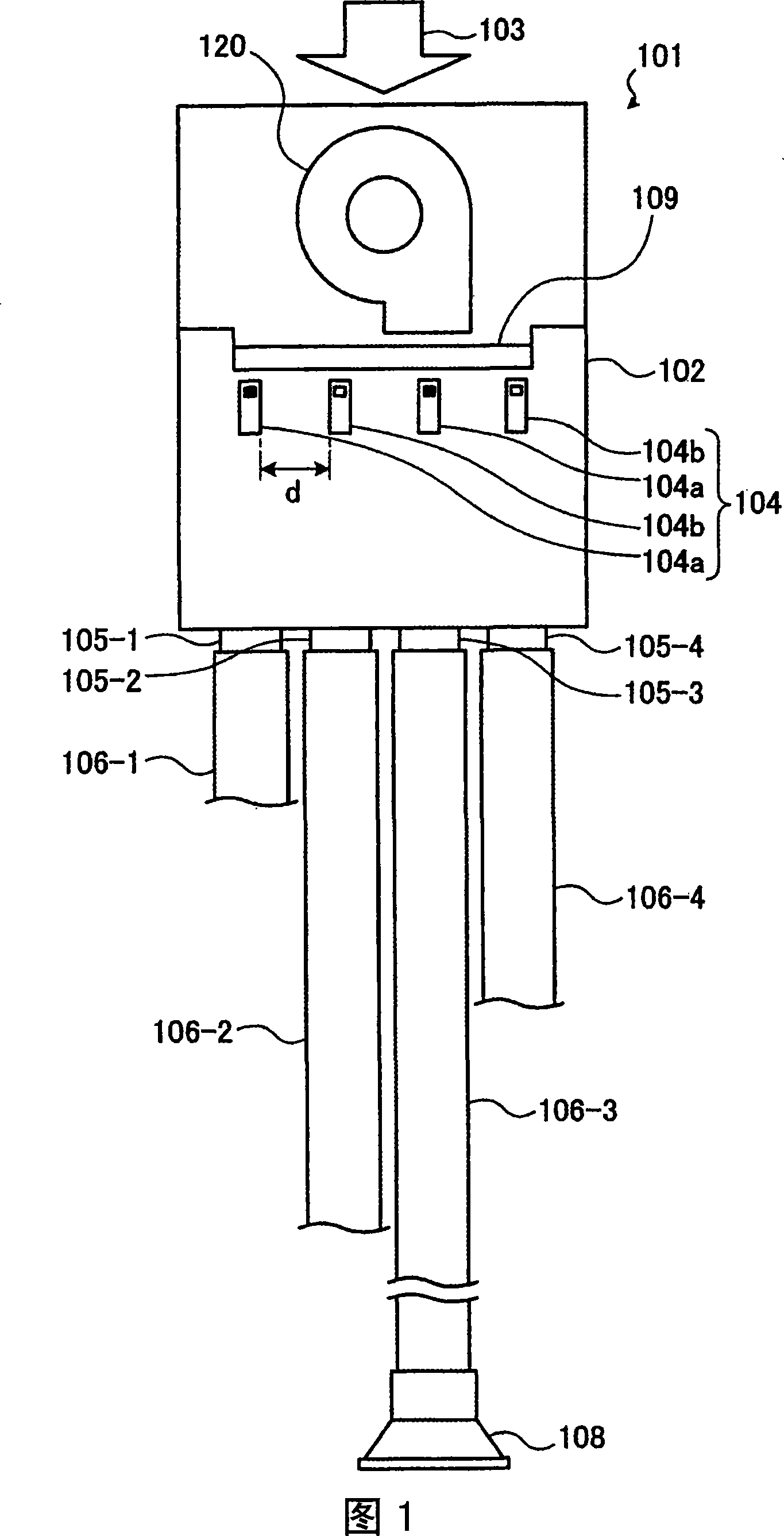

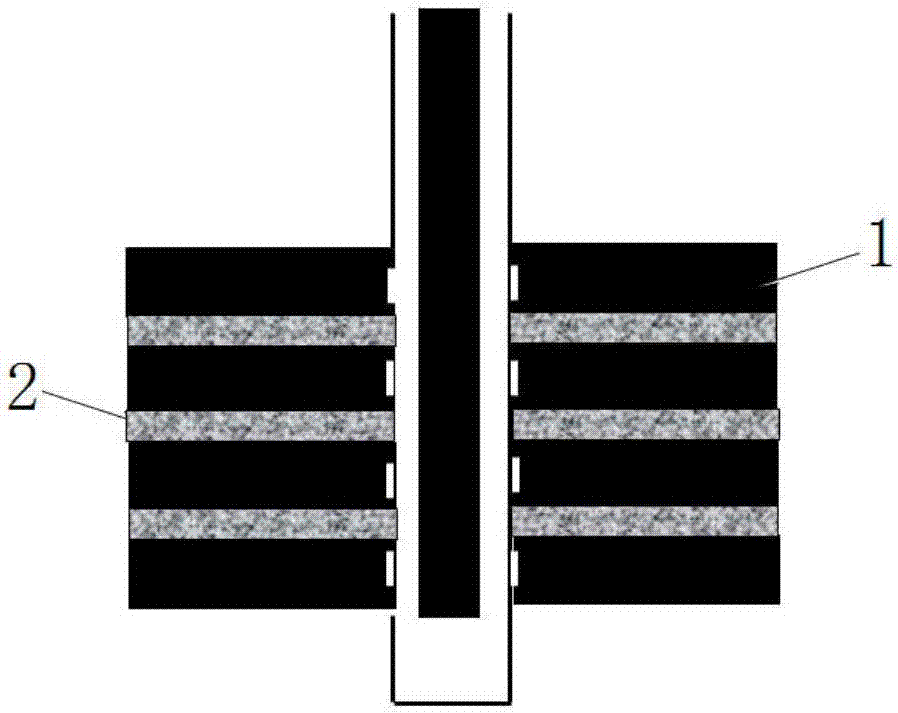

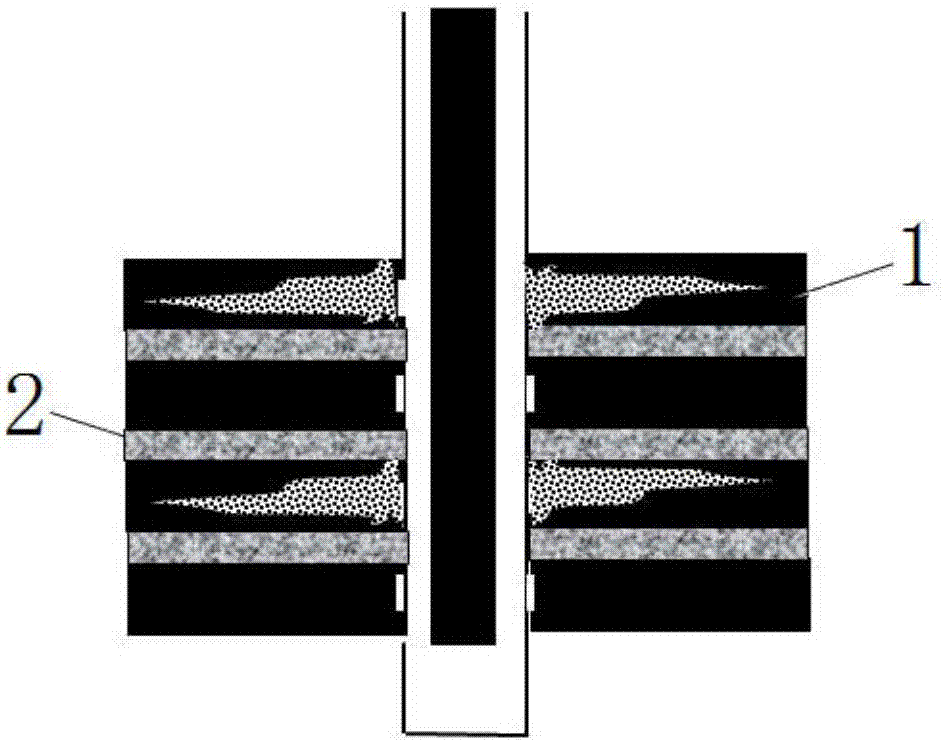

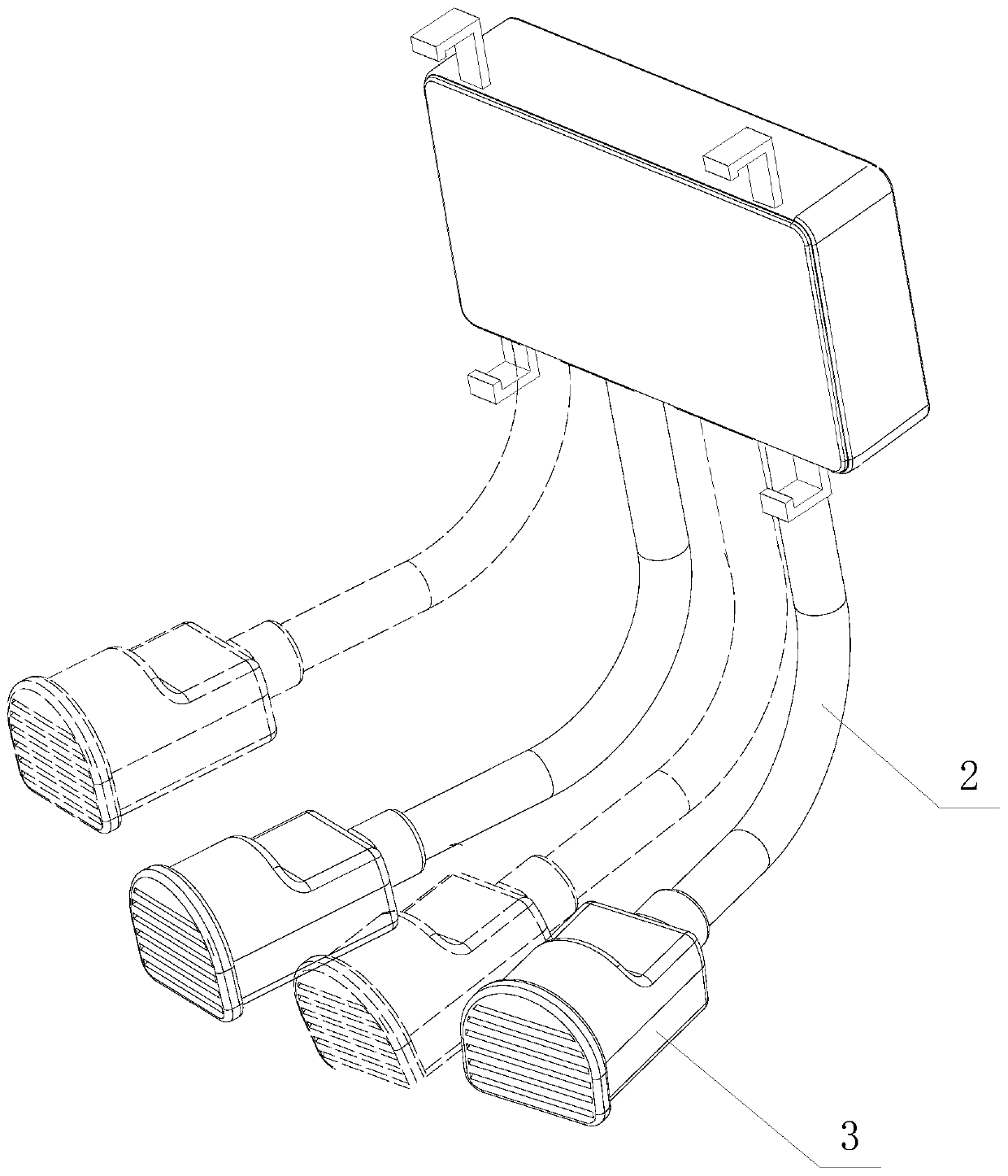

Air ion conveyance device and air ion conveyance system

InactiveCN101175510ASmall attenuationUniform supplyElectrical apparatusLighting and heating apparatusEngineeringAir conditioning

The present invention provides an air ion conveyance device as well as an air ion conveyance system, for example, for an air conditioning facility and conveys air ions to rooms of a house etc. The air ion conveyance device has an air ion production device unit, air ducts, and a control device. The air ion production device unit is provided in a housing of a centralized ventilation device and has positive ion production devices and negative ion production devices that are alternately arranged with a spacing in between, the positive ion production devices generating positive ions in air fed from the outside, the negative ion production devices generating negative ions in the air. The air ducts are connected to joints provided at the housing and individually conveys air to rooms. The control device controls the air ion production device unit. The control device regulates, according to a request from each room, whether or not to produce air ions or the amount of production of ions.

Owner:THE SHIMIZU CONSTRUCTION CO LTD +1

Fracturing method for realizing effective partial pressure of dense heterogeneous reservoir stratum

ActiveCN107420081ASolve underutilized issuesOvercoming Inability to Retrofit AdequatelyFluid removalFiberFracturing fluid

A fracturing method for realizing the effective partial pressure of a dense heterogeneous reservoir stratum includes the steps of cutting to an artificial well bottom through a gauge cutter, conducting a pressure test on a shaft after well flushing till the test is qualified, selecting the point with the best physical property of the stratum as a perforation section or spot, conducting heat power perforation or heat power sandblast perforation, putting in a fracture drill tool to conduct first-grade fracturing construction, implementing general fracturing through fracturing liquid, replacing with sand-carrying fluid to enter the stratum, closing a well till a fracturing seam is closed, adding degradable fiber and a water-soluble temporarily plugging agent for blocking a fractured layer section, starting second-grade fracturing construction, repeatedly executing the steps of adding the degradable fiber and the water-soluble temporarily plugging agent and conducting fracturing construction according to the perforation hole number till all perforation sections are sufficiently refitted, and finally conducting well closing, well opening for gushing, production volume finding and well completing. Through the combination of multi-section fixed point perforation and the fiber and the water-soluble temporarily plugging agent, the opened fracturing seam is selectively blocked, an unused stratus is forced to be fractured and a new seam is created, and the aim of effective fracturing and sufficient refitting of all oil reservoirs can be achieved.

Owner:PETROCHINA CO LTD

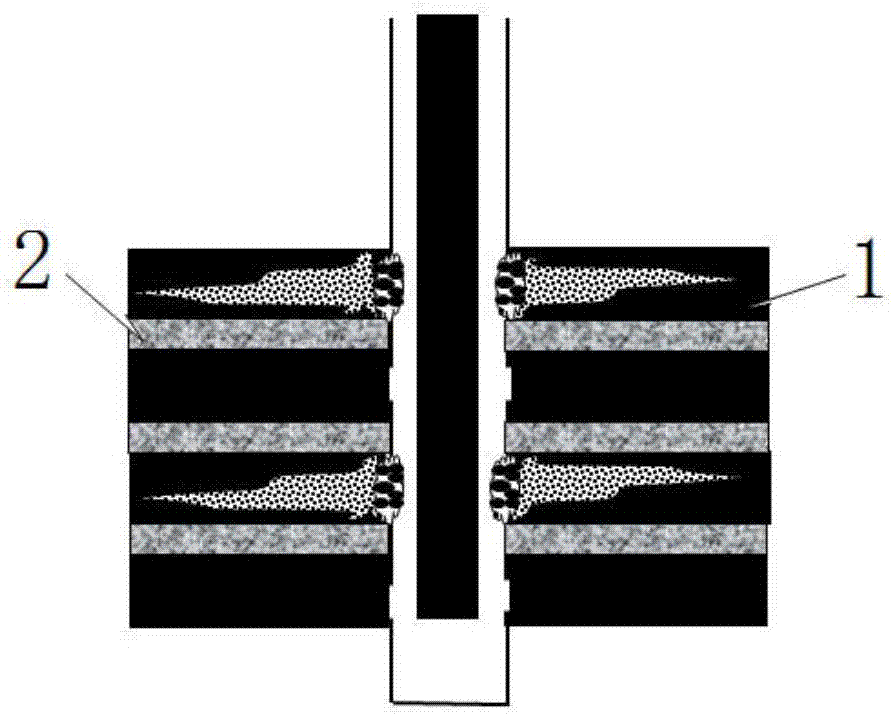

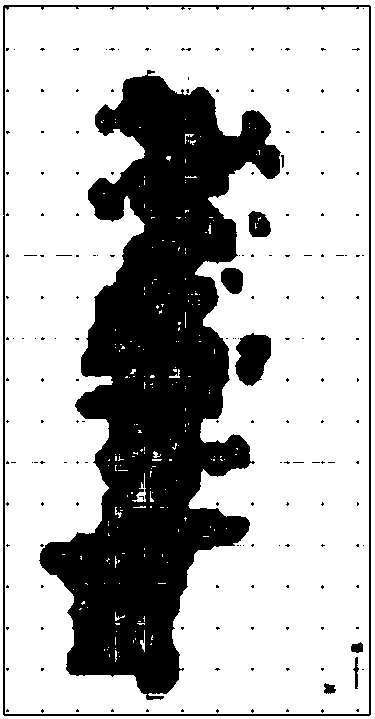

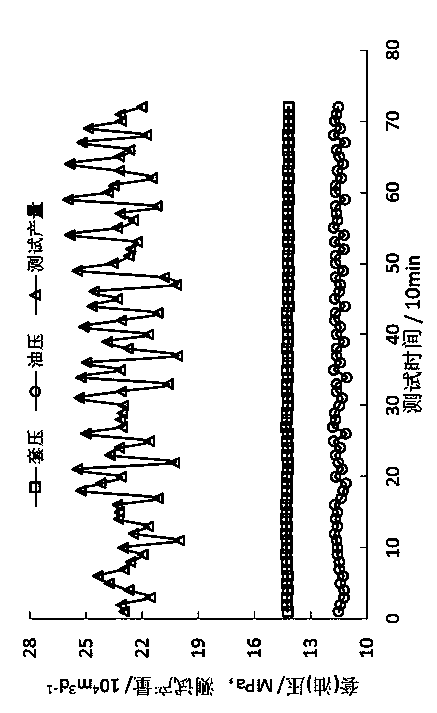

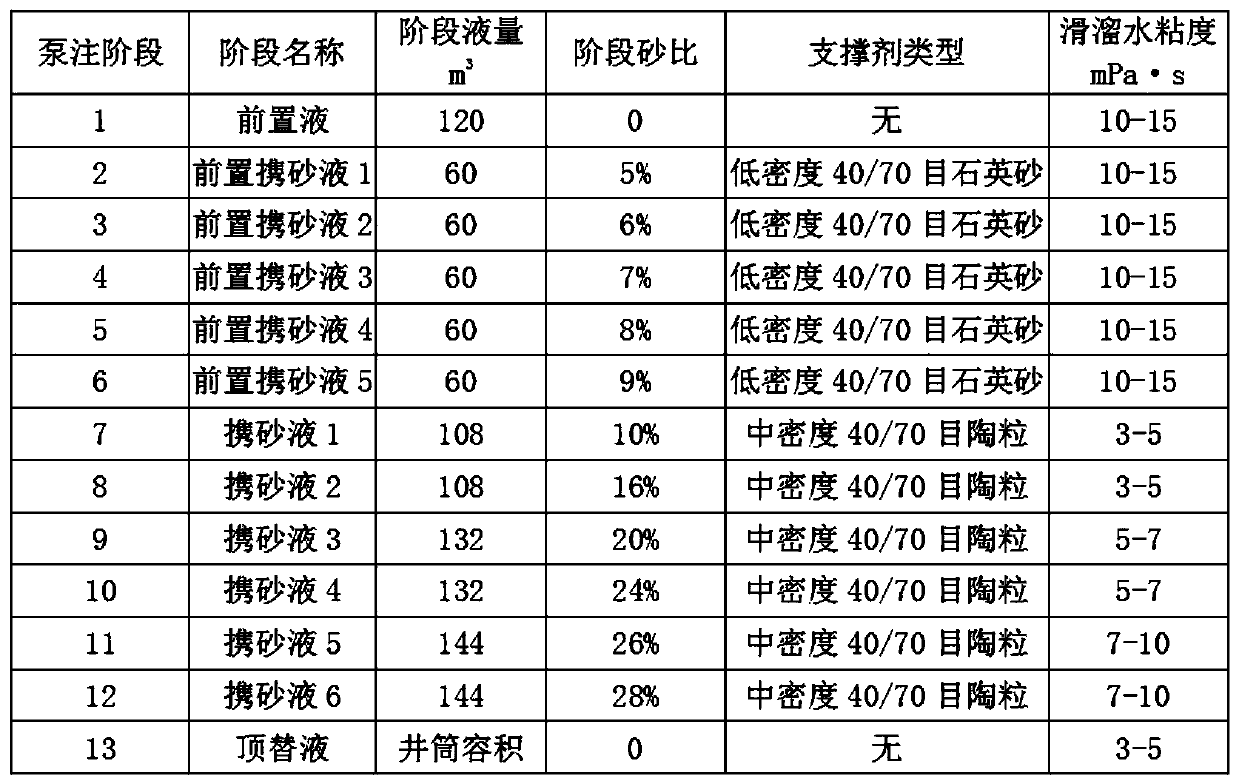

Fracturing method for improving laying effect of heterogeneous reservoir proppant

ActiveCN111396018AReduce construction frictionGuaranteed effective supportFluid removalDesign optimisation/simulationFracture controlGeotechnical engineering

The invention discloses a fracturing method for improving a laying effect of a heterogeneous reservoir proppant, and relates to the technical field of oil and gas field sand fracturing processes. According to the method, geological data of a target well are collected and evaluated; according to the target well reservoir permeability and the single artificial fracture control radius, the segment length, the cluster spacing and the cluster number are designed; the artificial fracture length, the flow conductivity, the fracturing fluid scale and the fracturing proppant scale are designed on the basis of achieving the optimal yield; testing fracturing is conducted on the target well, and the reservoir fracturing fluid efficiency of the target well is determined; the usage amounts of prepad fluid, prepad sand-carrying fluid and sand-carrying fluid are calculated according to the determined fracturing fluid scale and the determined fracturing fluid efficiency correspondingly; the use amountof displacing fluid is determined according to the volume of a target well shaft; and a pump injection program is generated according to the determined proppant scale as well as the determined amountsof the prepad fluid, the prepad sand-carrying fluid, the sand-carrying fluid and the displacing fluid, and fracturing operation is implemented. The method solves the technical problem that unsupported and invalid seams are formed in the fracturing process due to the fact that the proportion of the prepad fluid cannot be completely matched with a reservoir stratum in traditional fracturing design.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

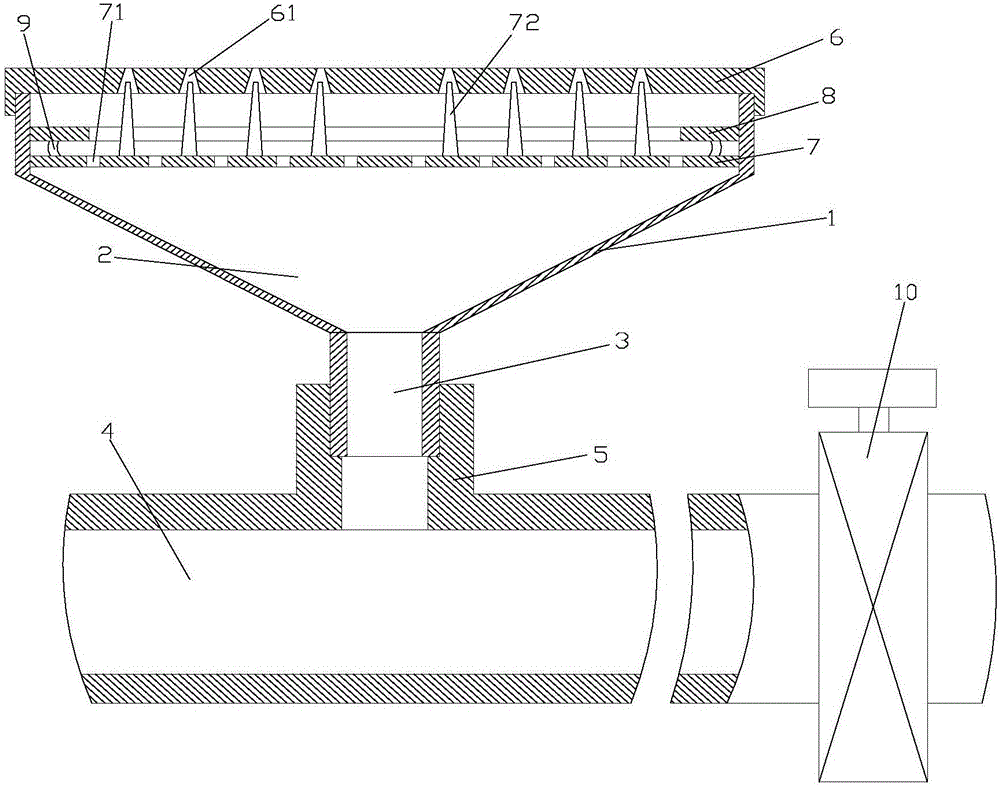

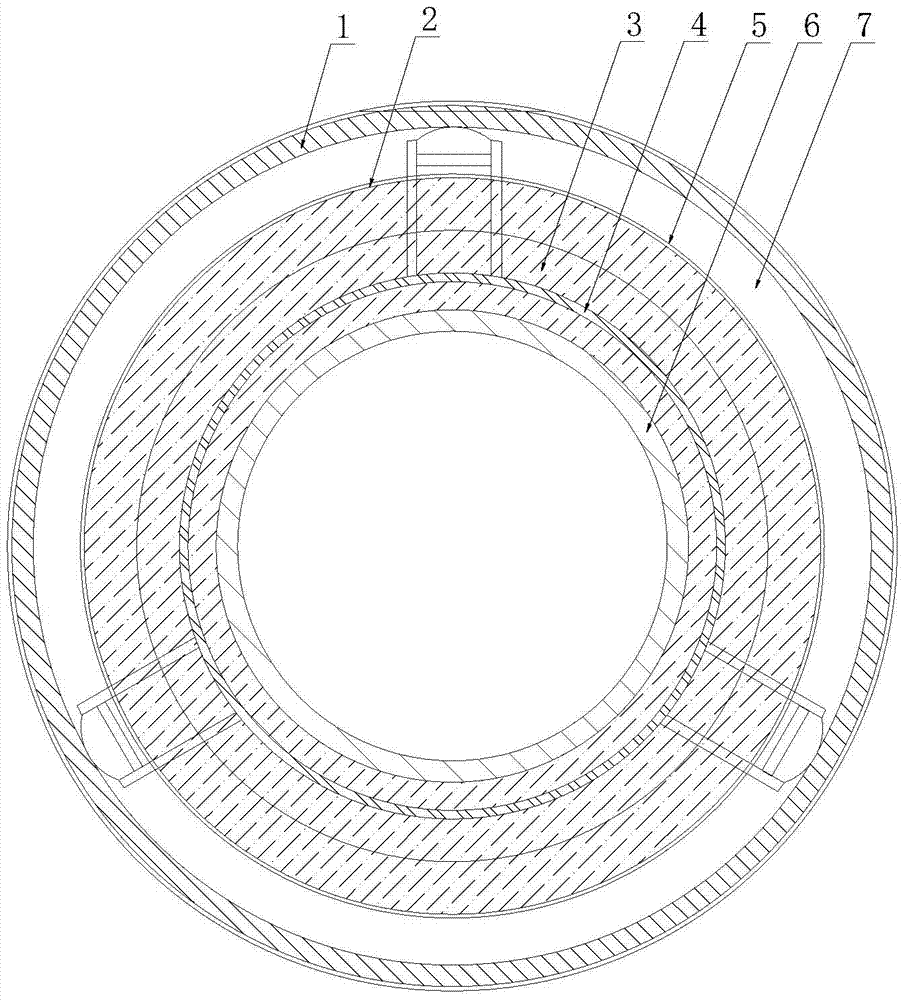

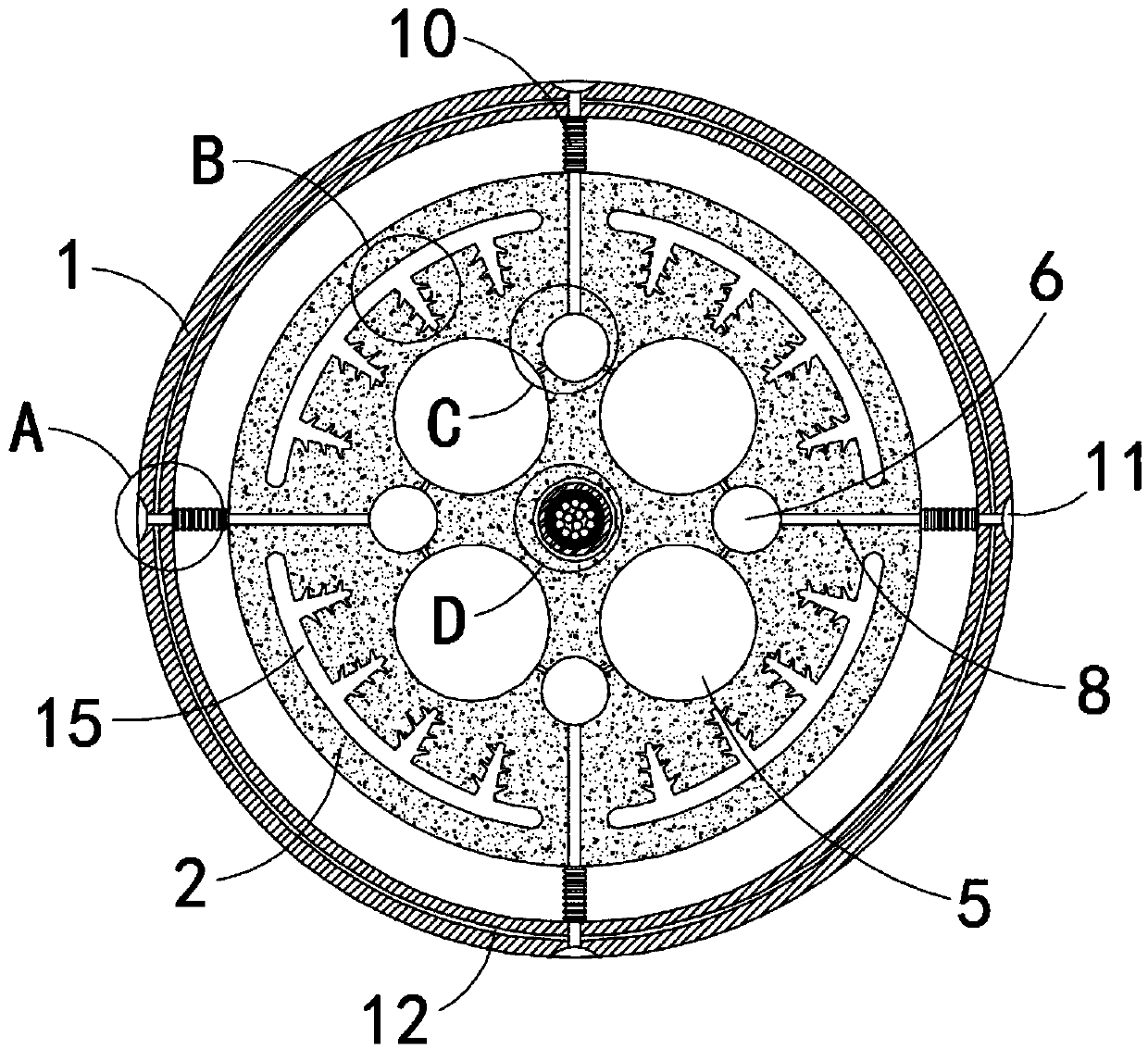

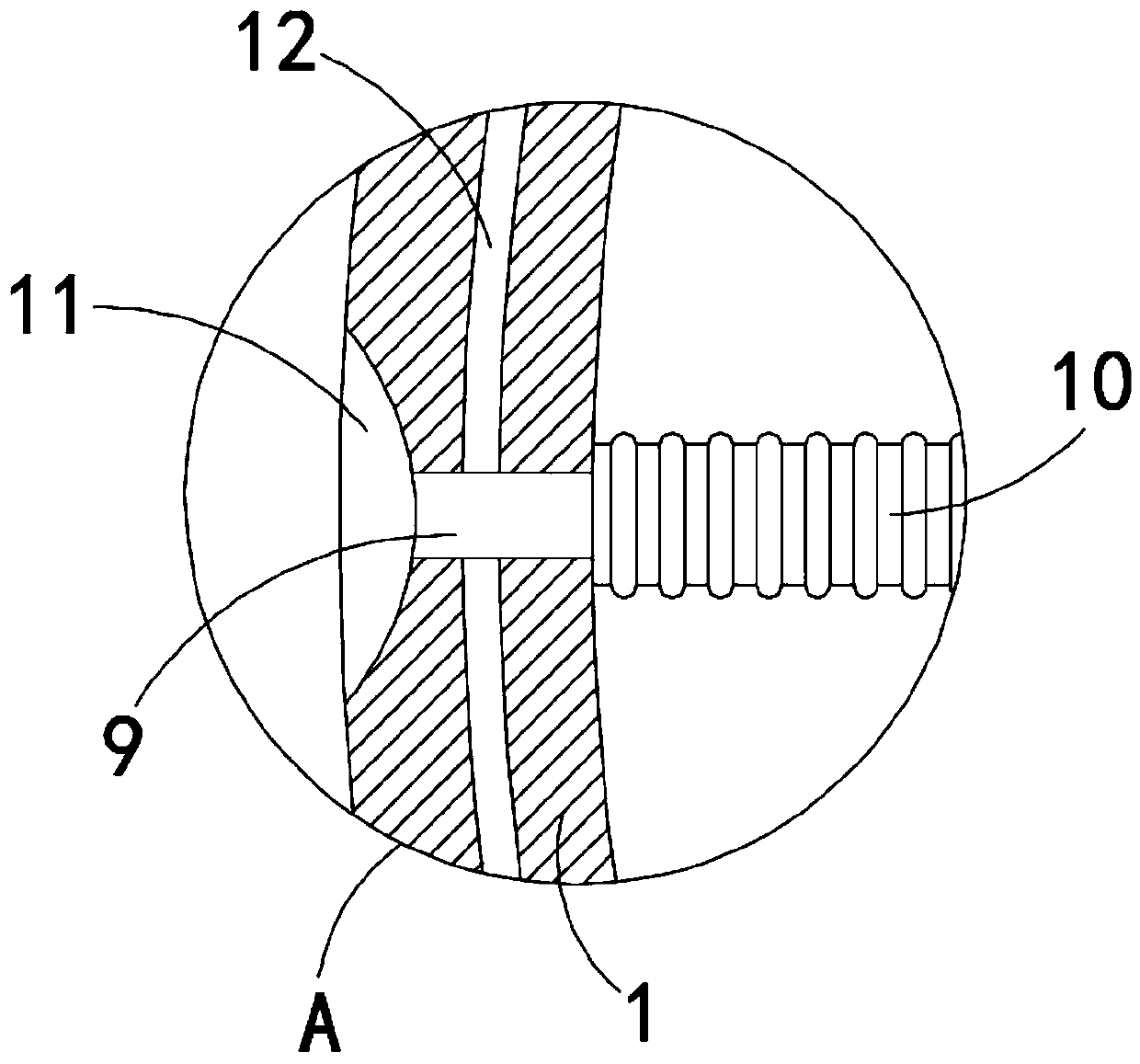

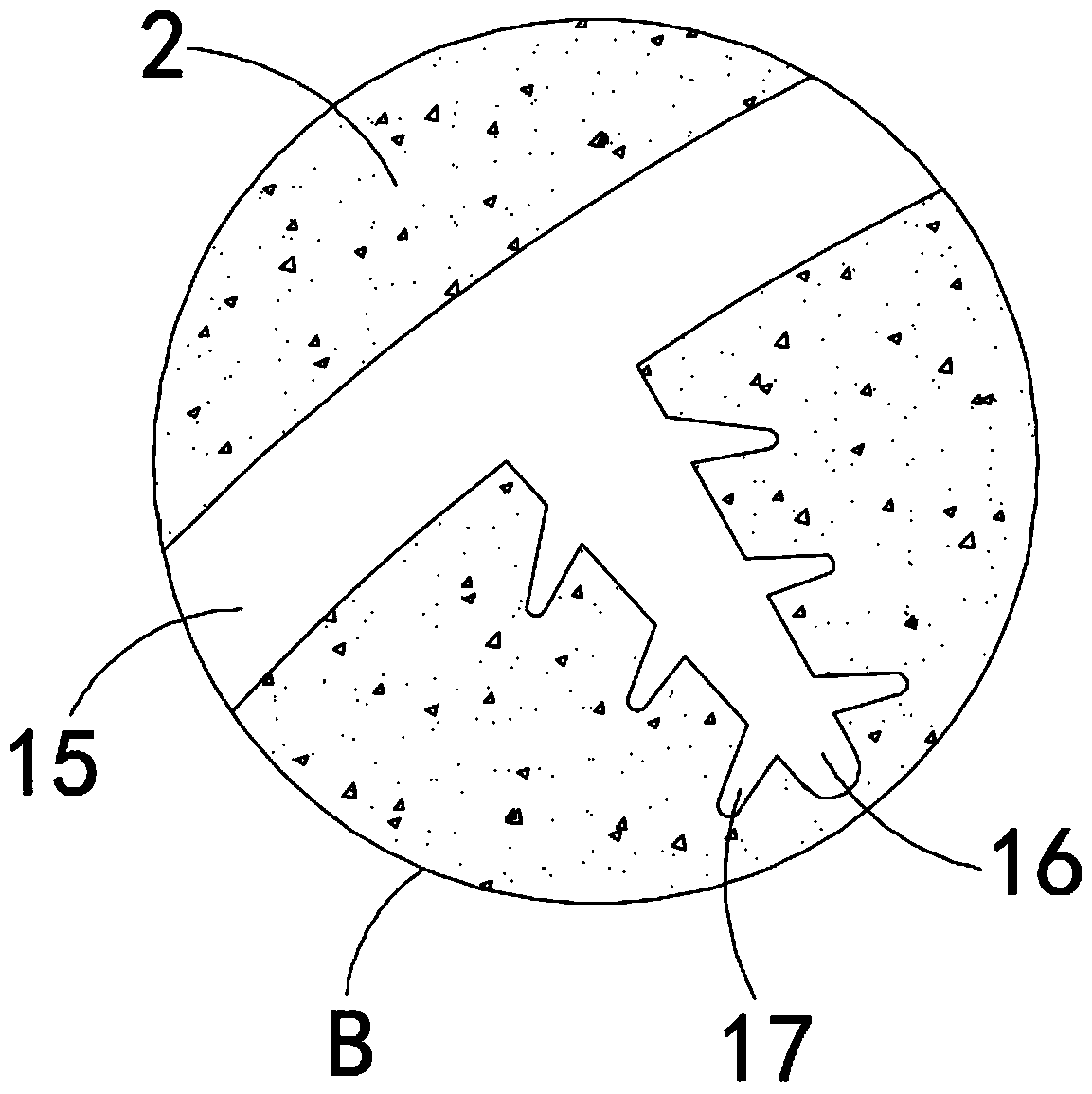

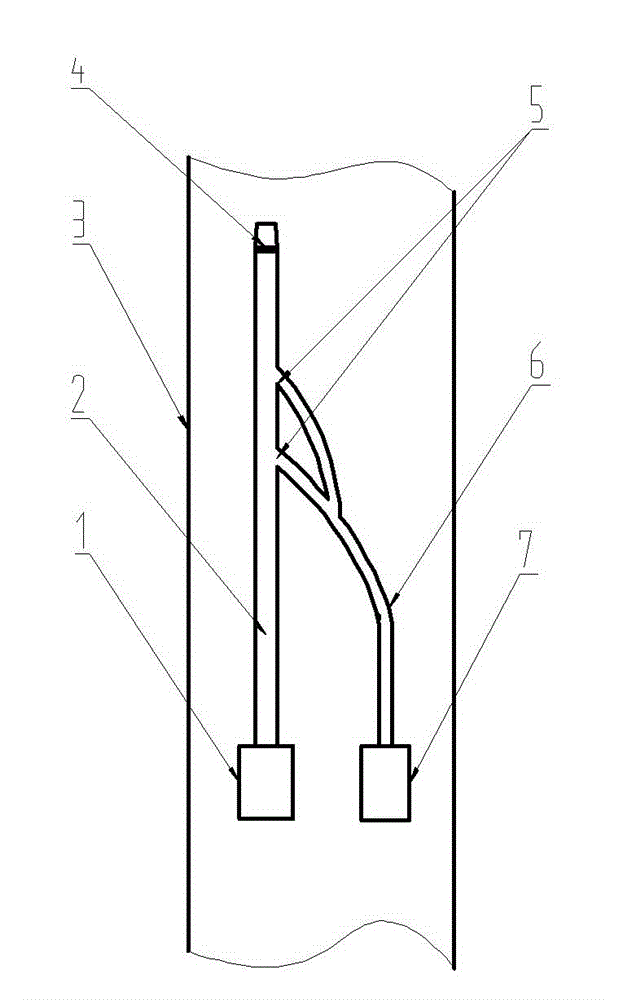

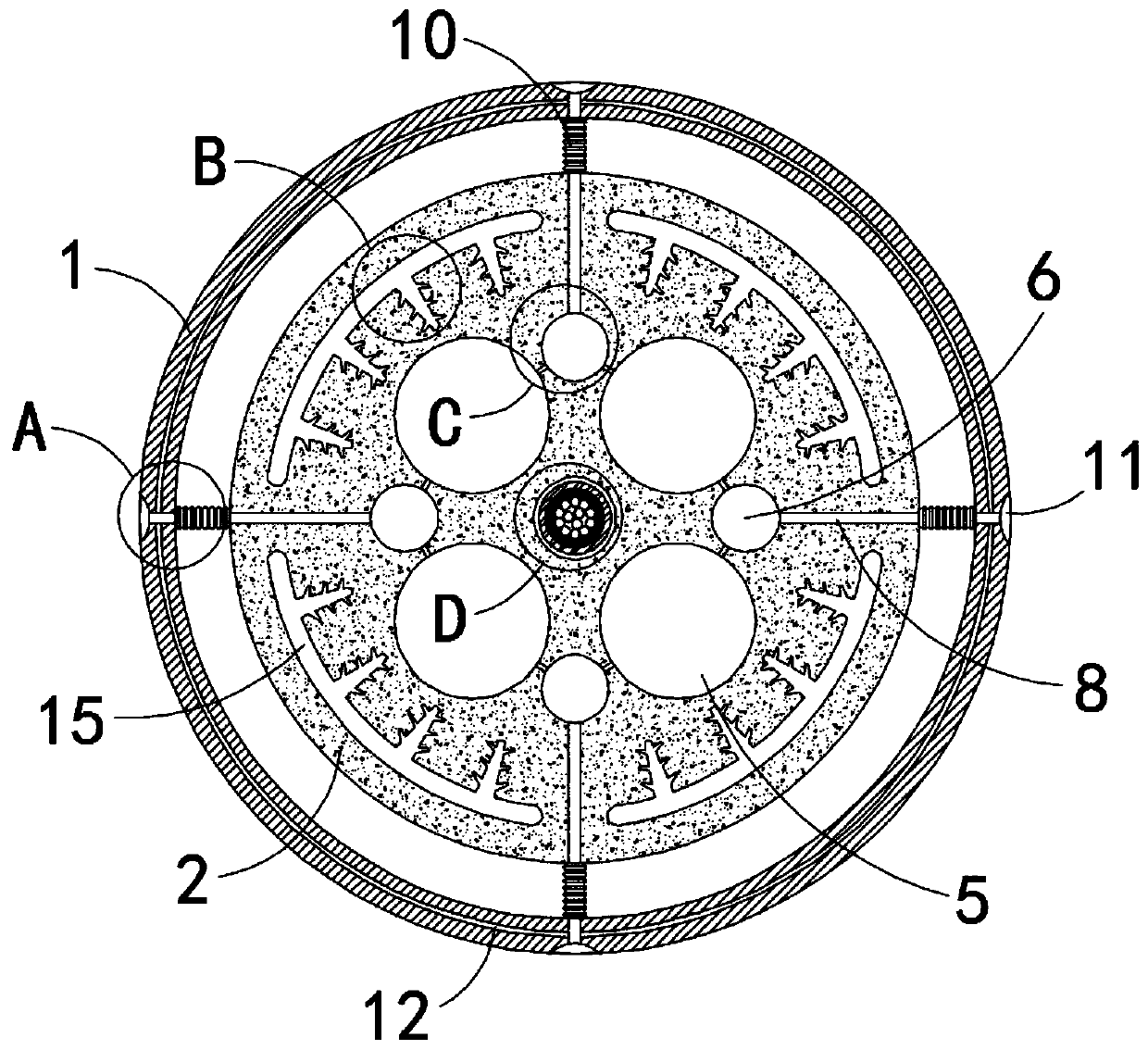

Aeration device for sewage treatment

InactiveCN107434307AIncrease usage intensityReduce stress concentrationWater aerationSustainable biological treatmentInternal cavityAeration

The invention discloses an aeration device for sewage treatment. The aeration device comprises an aerator shell (1) and an aeration tube (4), an internal cavity (2) is arranged in the aerator shell (1), connectors (3) are arranged at one end of the aerator shell (1), and the other end of the aerator shell (1) is a gas outlet end; the aeration tube (4) is provided with a plurality of tube joints (5), the connectors (3) are jointed in the tube joints (5) and are in threaded connection with tube joints (5); an aeration plate (6) is jointed at the gas outlet end of the aerator shell (1), the aeration plate is in threaded connection with the aerator shell (1), and the aeration plate (6) is provided with a plurality of aeration holes (61); and a gas guiding plate (7) is arranged in the internal cavity (2), the gas guiding plate (7) is provided with a plurality of gas guiding holes (71), and the inner wall of the internal cavity (2) is provided with an annular fixed ring (8). The aeration device has the advantages of overcoming of shortcomings in the prior art, and reasonability and novelty in structural design.

Owner:成都市瑞焱科技有限公司

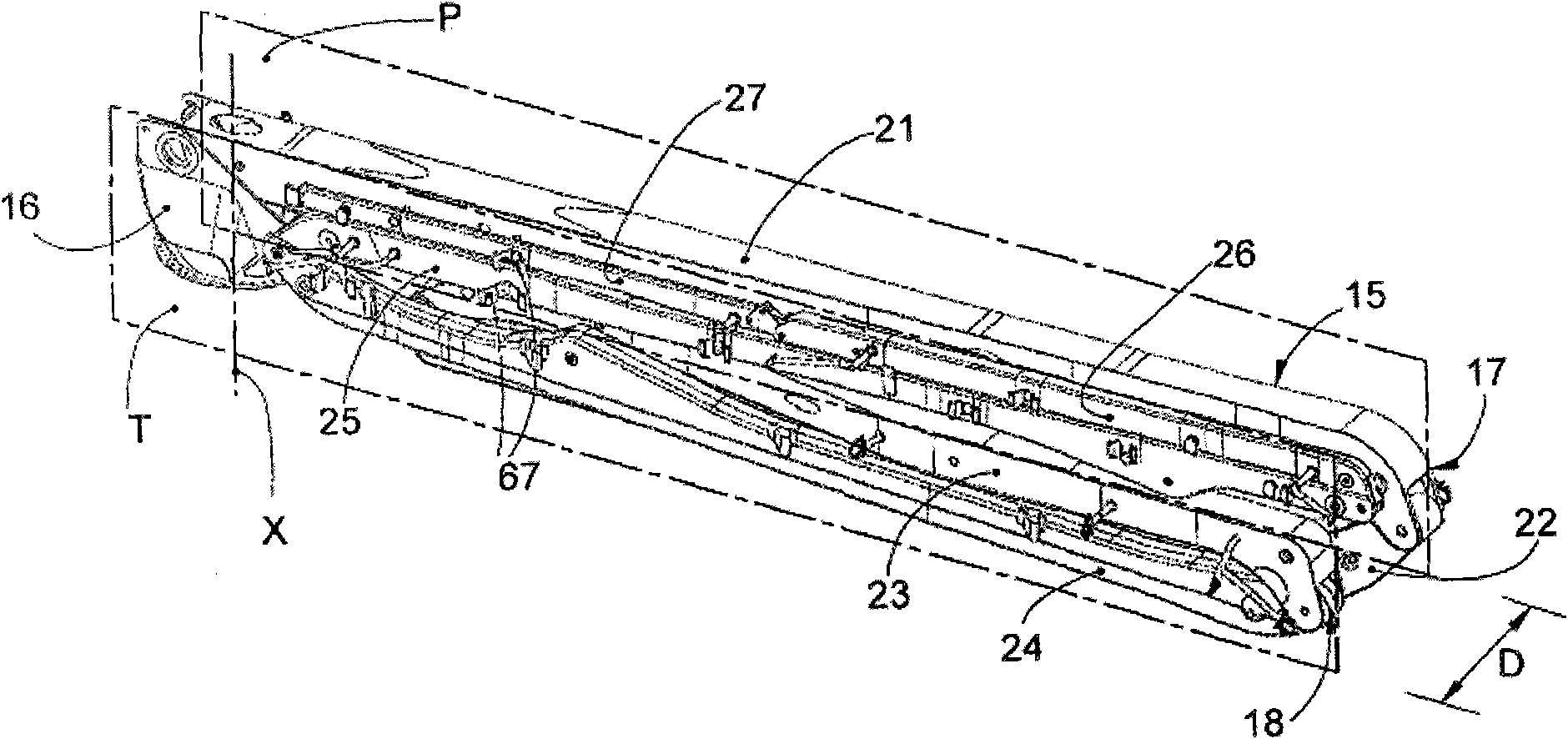

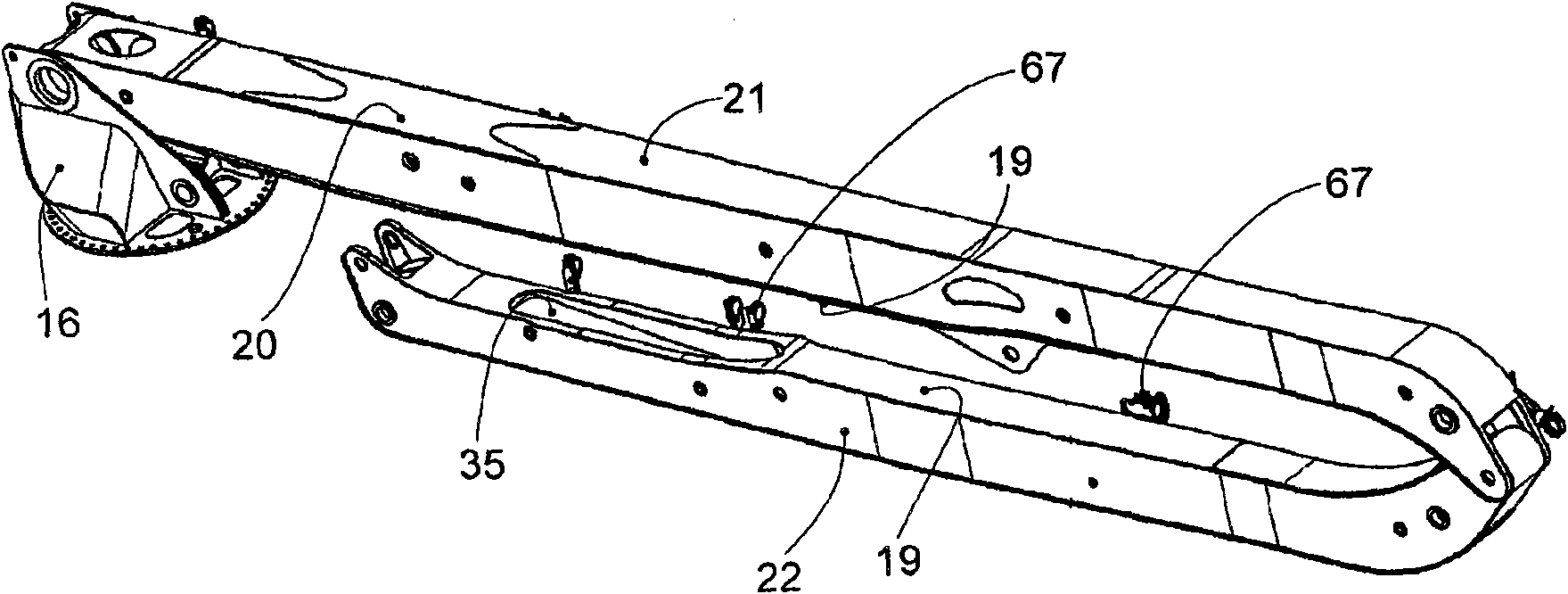

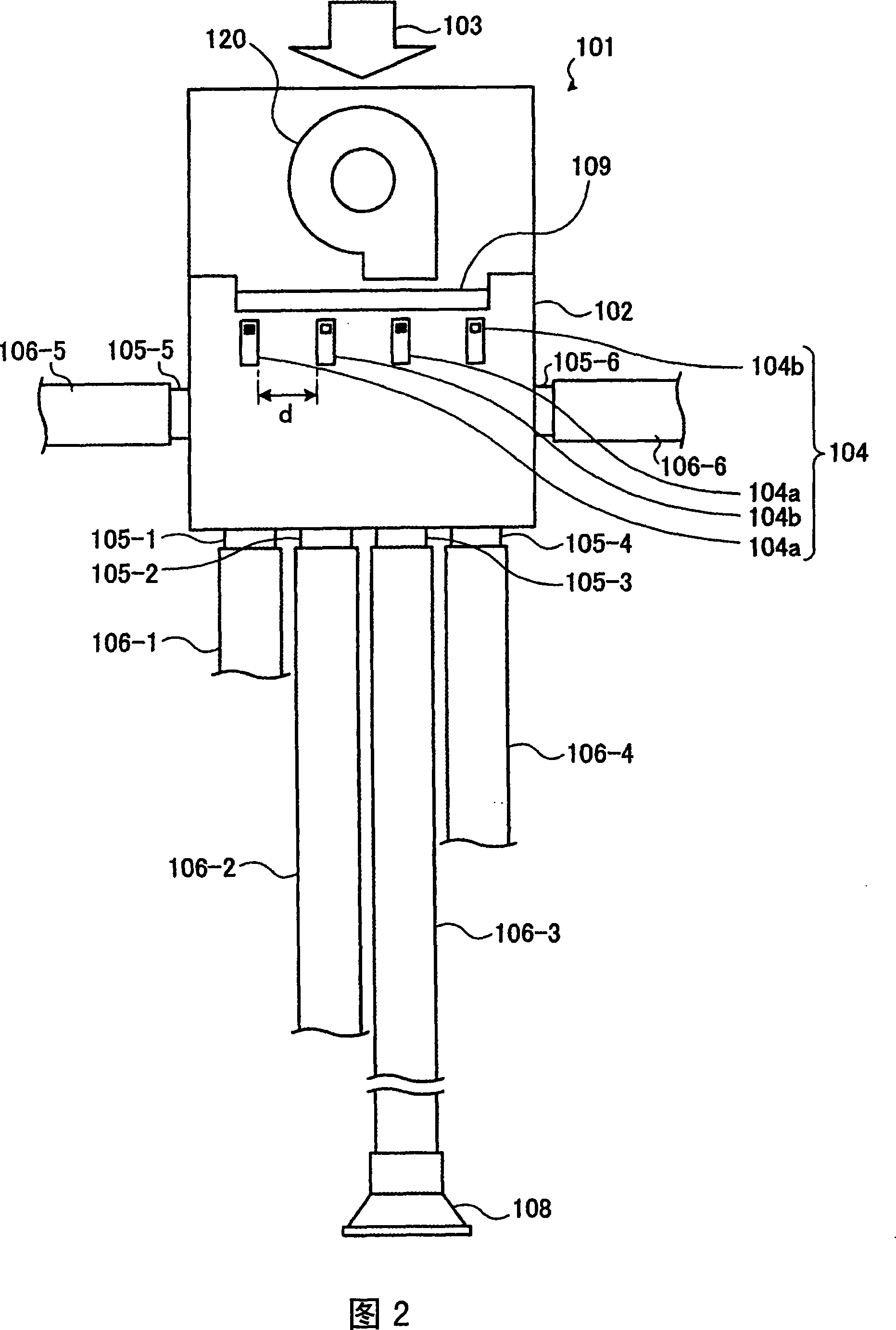

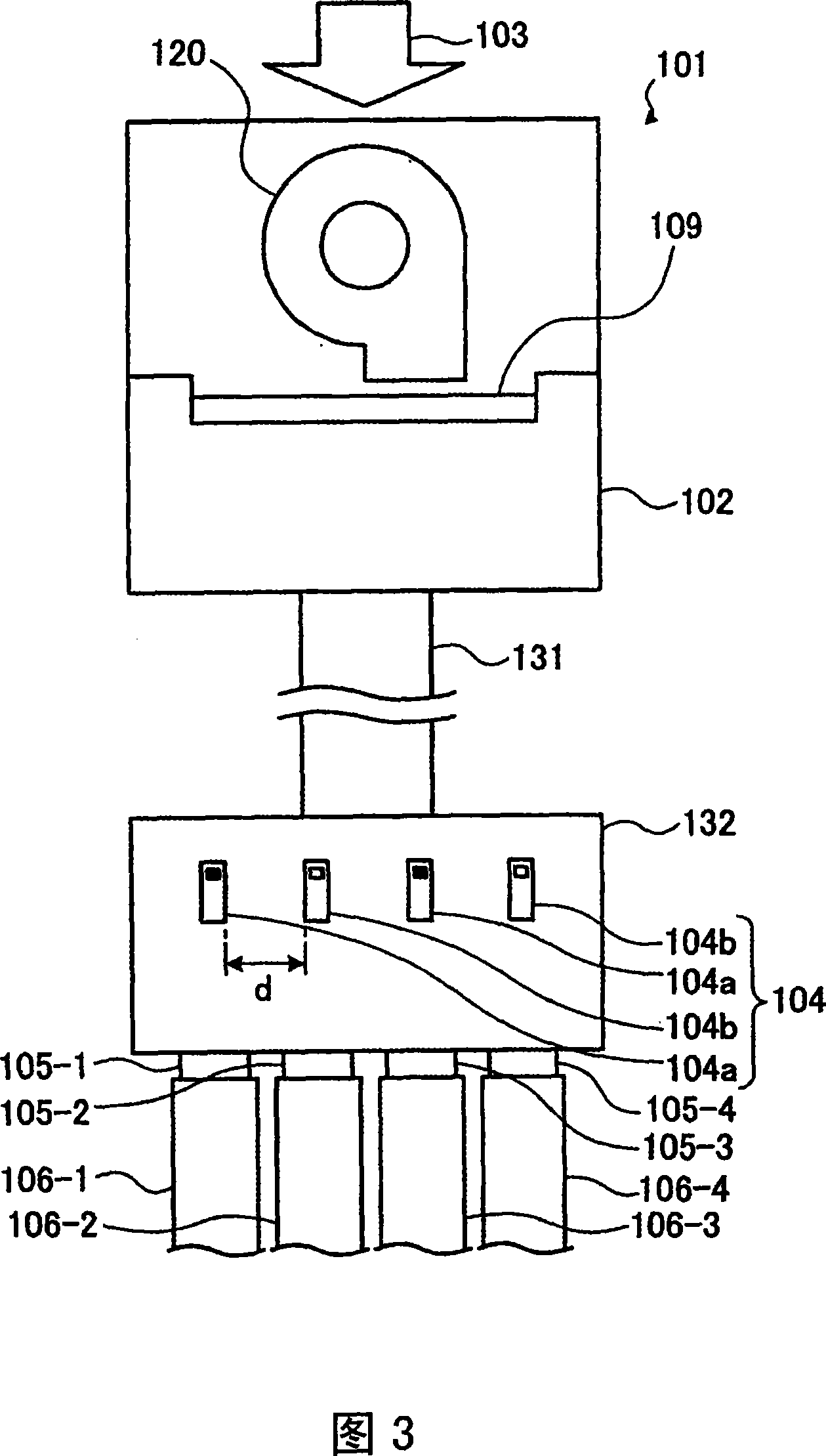

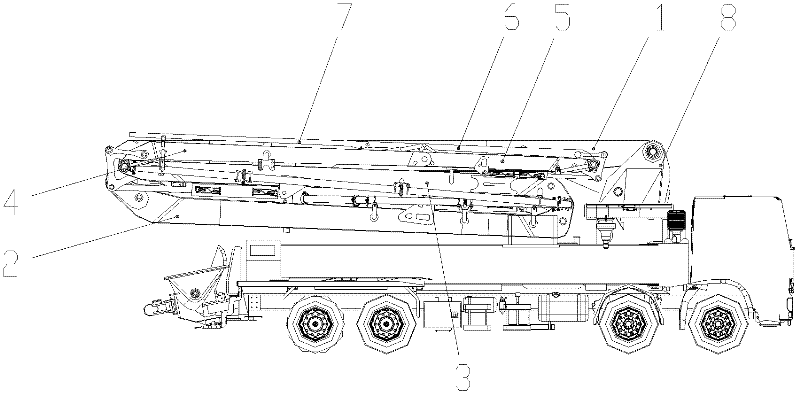

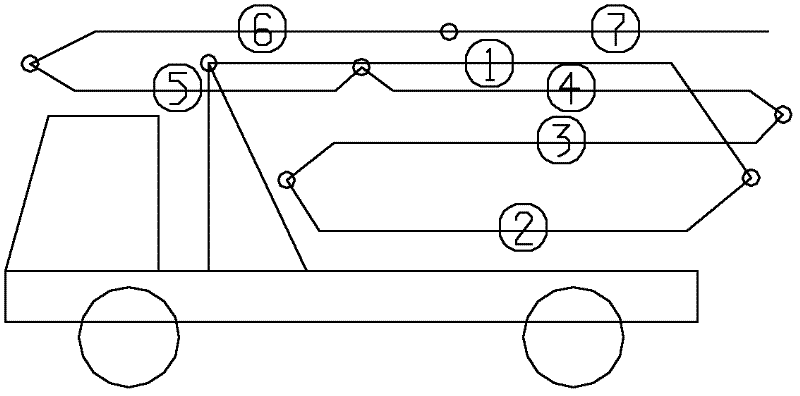

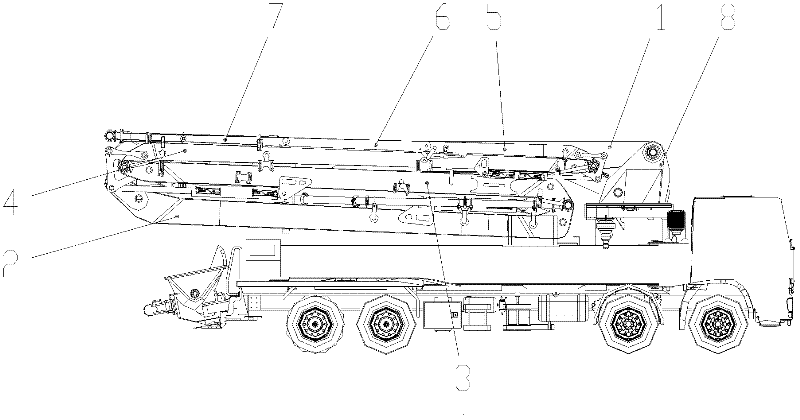

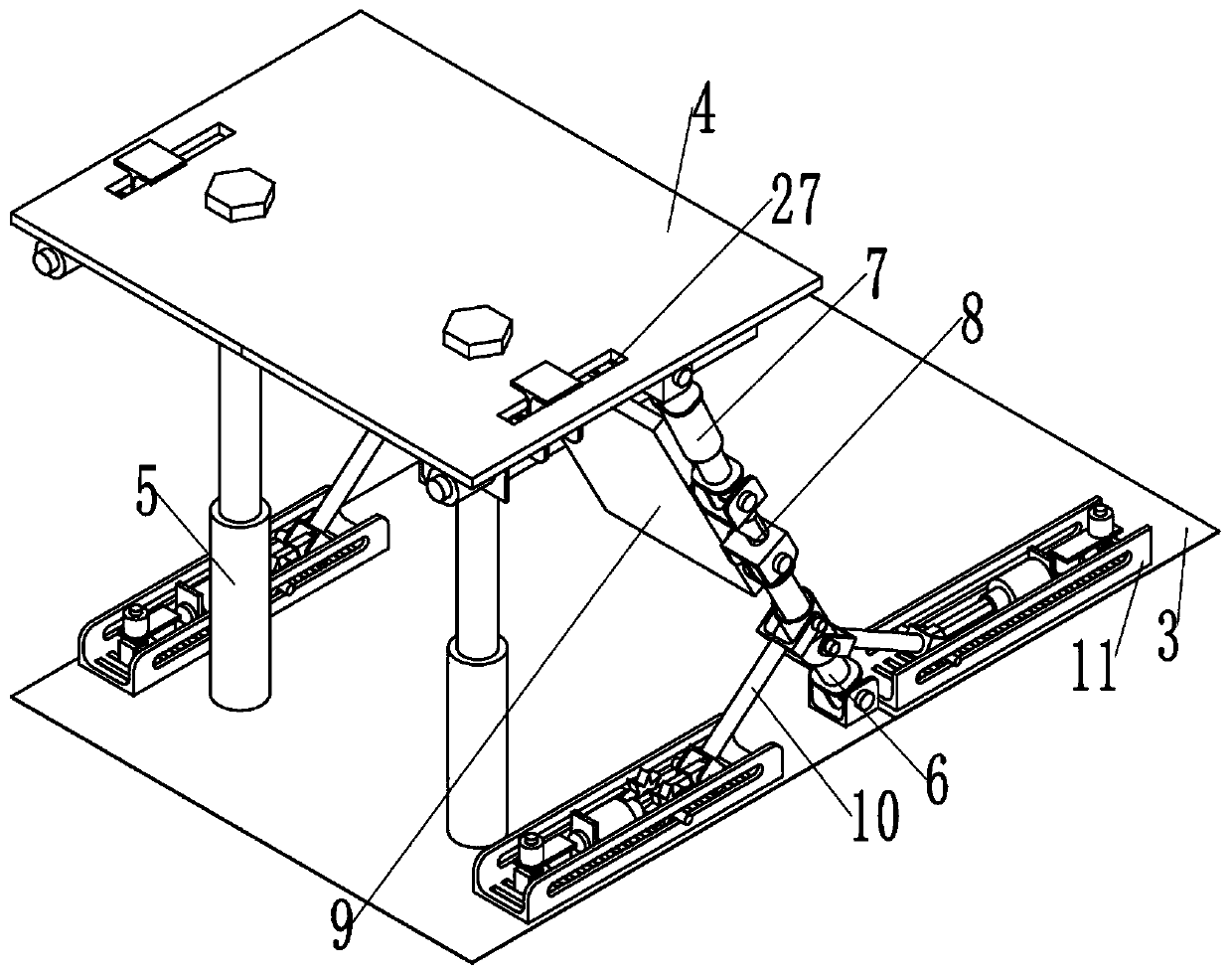

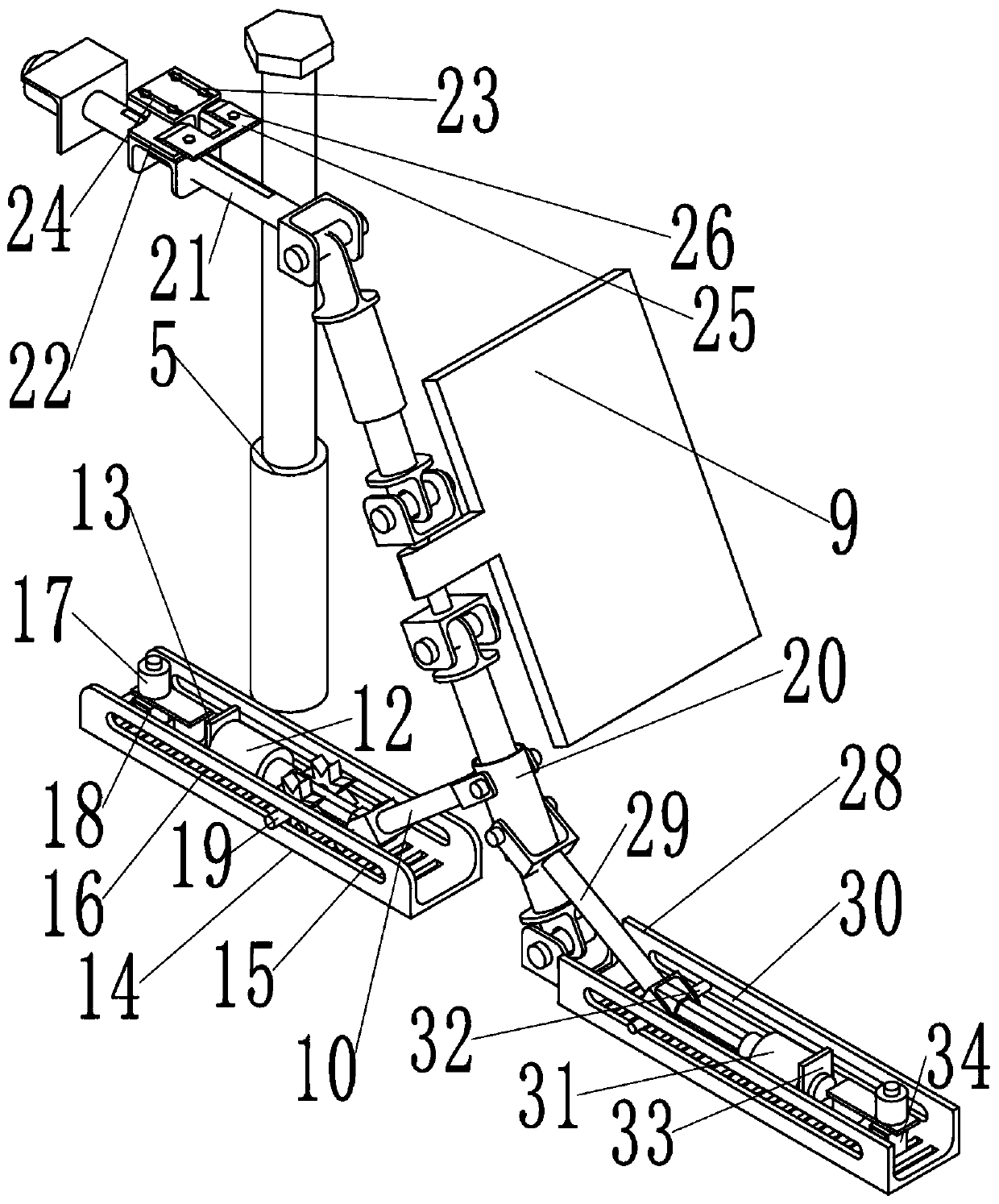

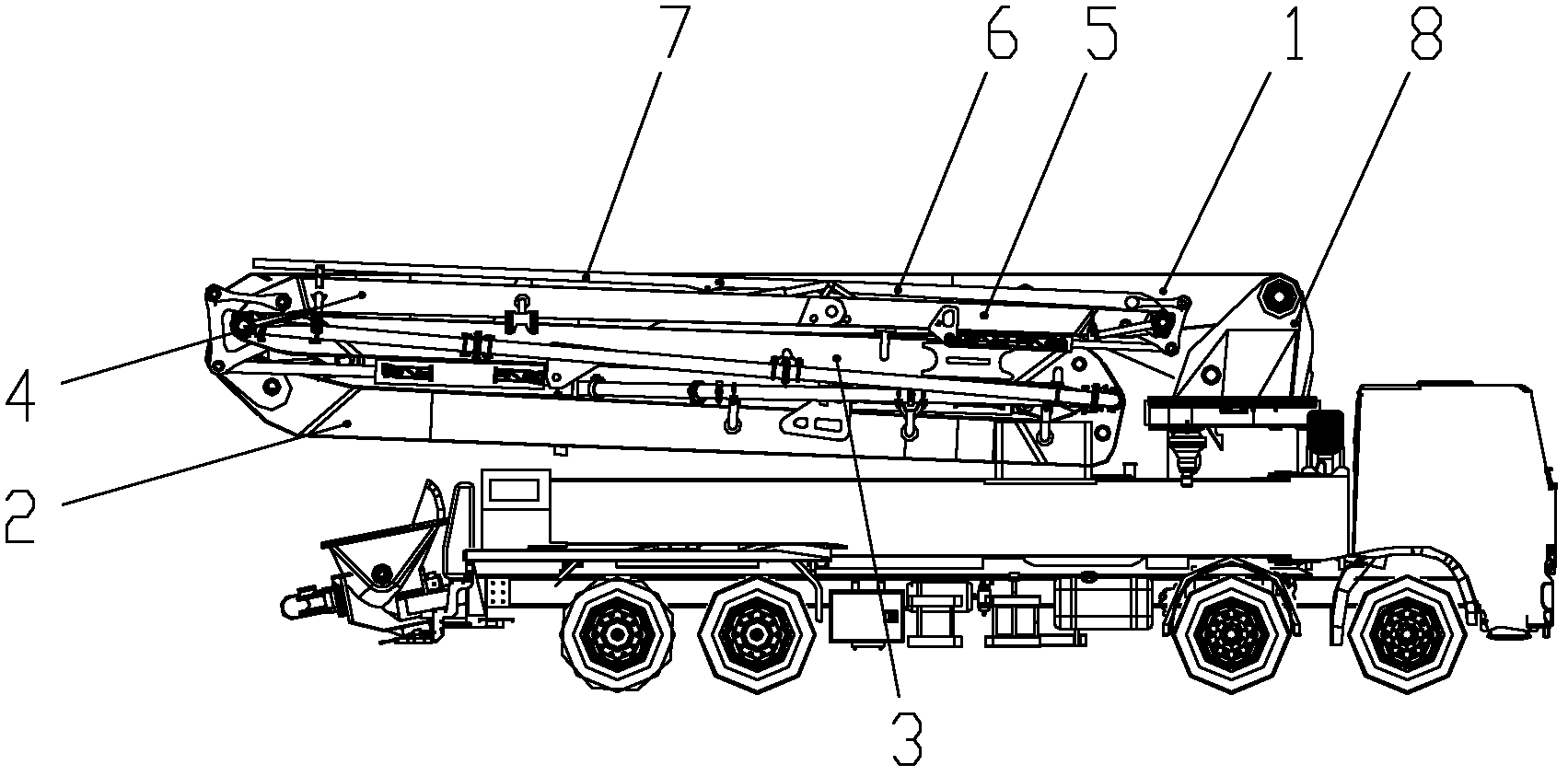

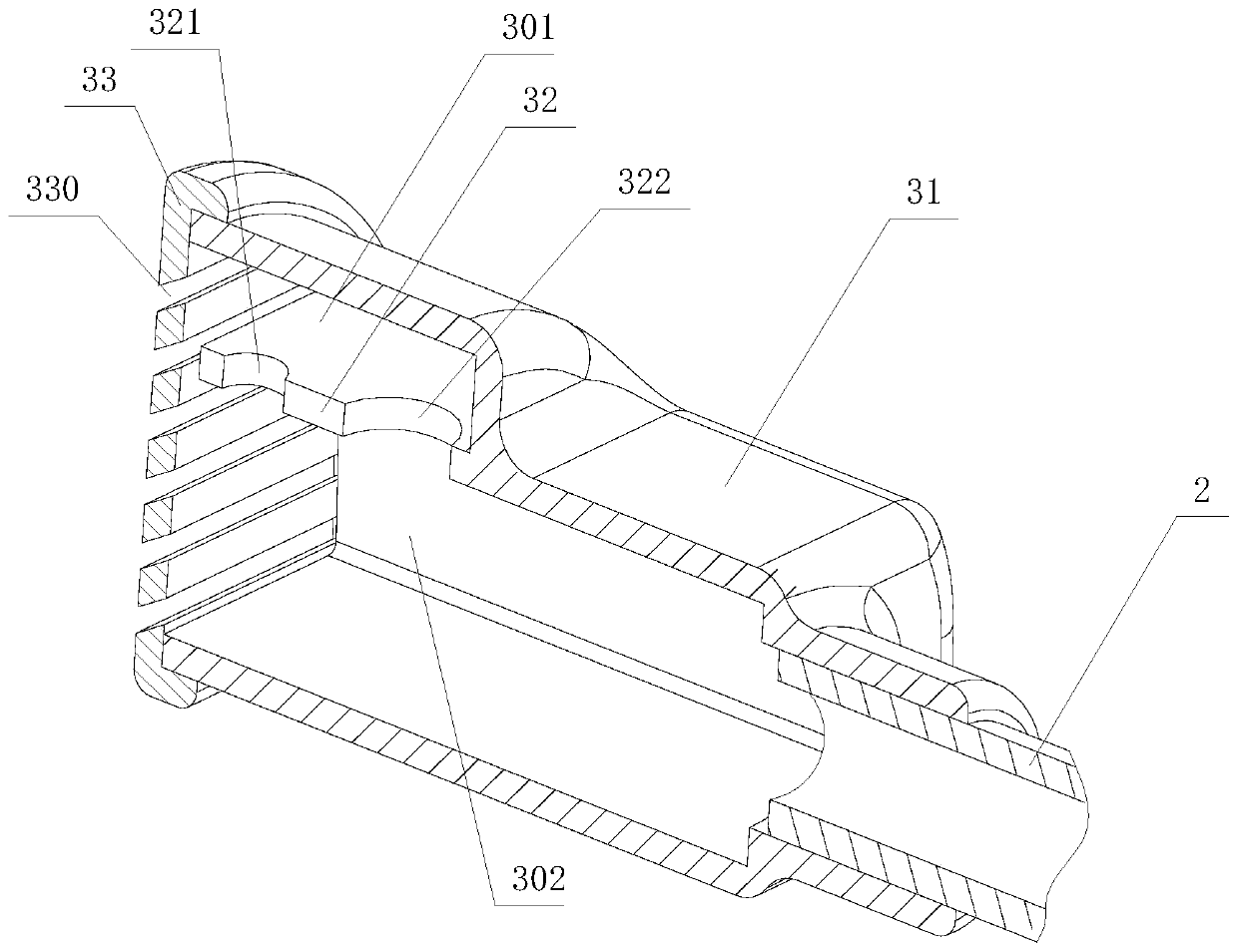

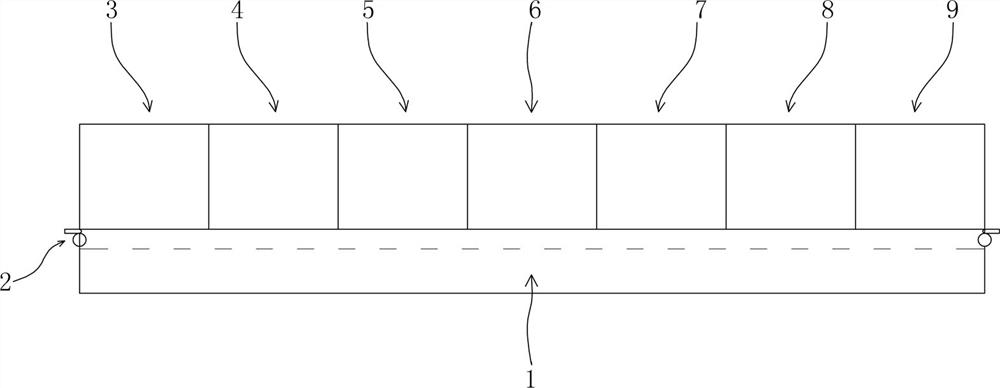

Concrete pump truck and arm support thereof

ActiveCN102518305ASmall sizeExtend the conveying distanceBuilding material handlingHoisting equipmentsStructural engineeringConcrete pump

The invention provides an arm support of a concrete pump truck, which can be folded and unfolded. The arm support of the concrete pump truck comprises seven sections of arms which are hinged in sequence. The seven sections of arms are basically arranged into five mutually staggered straight lines, and at least the last two sections of arms are on the same straight line. Because the seven sections of arms are basically arranged into five mutually staggered straight lines, the overall size of the arms can be greatly reduced, and the requirements of the road running condition of the concrete pump truck can be easily met. In addition, when the arm support is folded, the last two sections of arms are on the same straight line, thus the flexibility and the operability of the arm support fabric can be greatly improved. The invention further provides the concrete pump truck with the arm support.

Owner:ZOOMLION HEAVY IND CO LTD

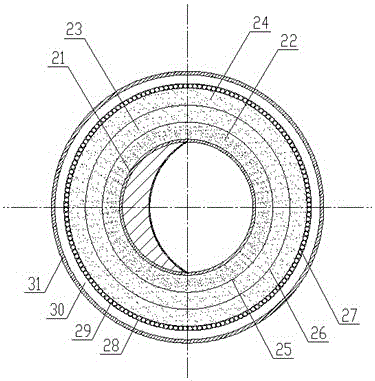

Prefabricated buried steam heat-preservation pipe with high heat preservation performance

InactiveCN103697289AReduce thicknessReduce consumptionThermal insulationPipe protection by thermal insulationSurface layerEngineering

The invention belongs to the technical field of heat-preservation pipelines, and relates to a prefabricated buried steam heat-preservation pipe with high heat preservation performance. The pipe sequentially consists of a working steel pipe, a heat-preservation layer, a rolling bracket and an outer protective steel pipe from inside to outside, wherein the rolling bracket is hooped on the working steel pipe; an air layer is formed between the heat-preservation layer and the outer protective steel pipe; an anticorrosive layer is arranged on the outer surface of each of the working steel pipe and the outer protective steel pipe. The pipe is characterized in that the heat-preservation layer is obtained by wrapping aluminum foil reflecting cloth and a nanometer heat insulating material (DR06), and the outer surface layer of the heat-preservation layer is wrapped by glass cotton silk fiber cloth. The prefabricated buried steam heat-preservation pipe with high heat preservation performance is scientific and reasonable in structural design and higher in innovativeness, and has the advantages of low heat consumption, high conveying temperature, capability of greatly prolonging the conveying distance and lowering the manufacturing, transportation and construction cost, and the like.

Owner:中投(天津)智能管道股份有限公司

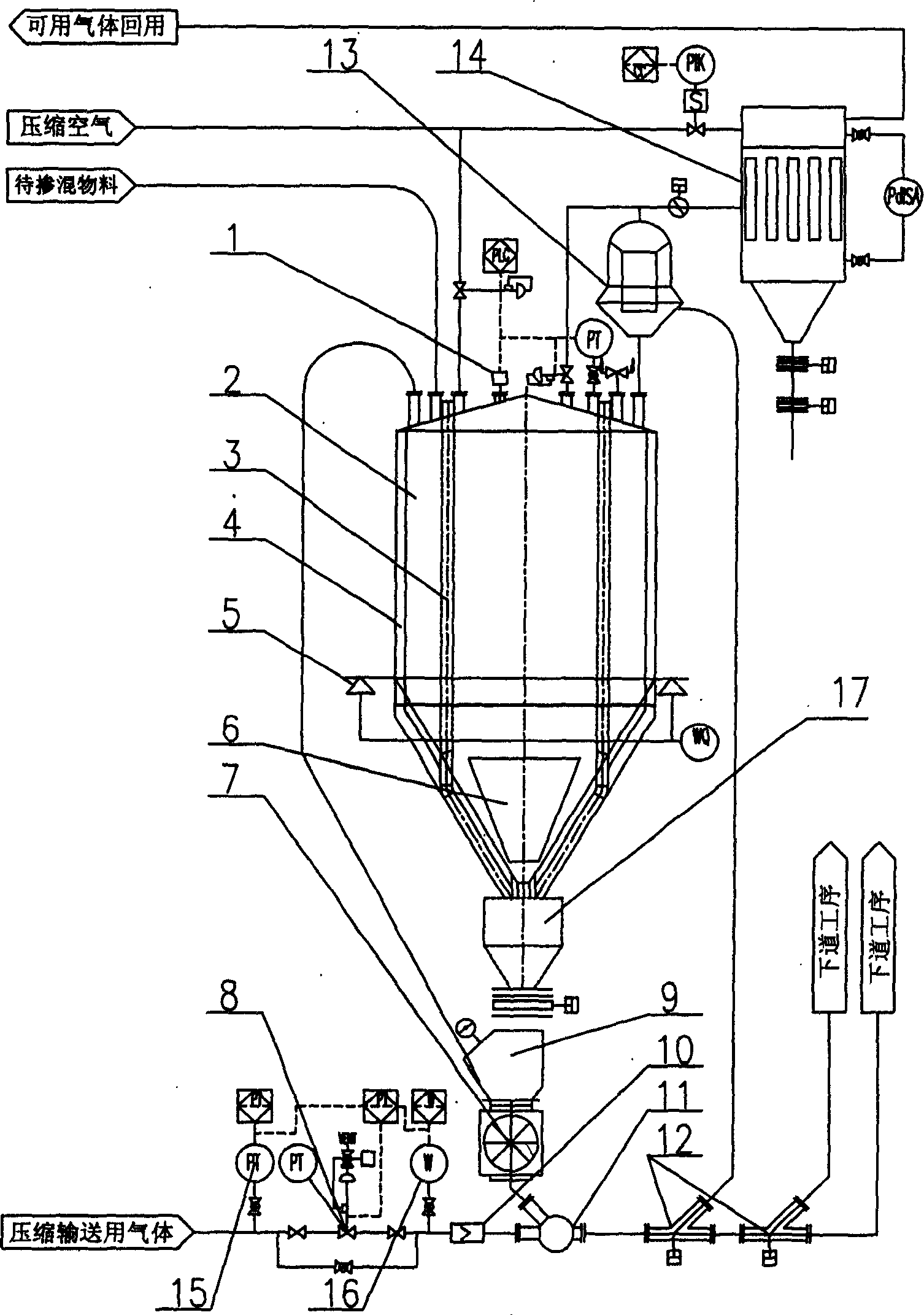

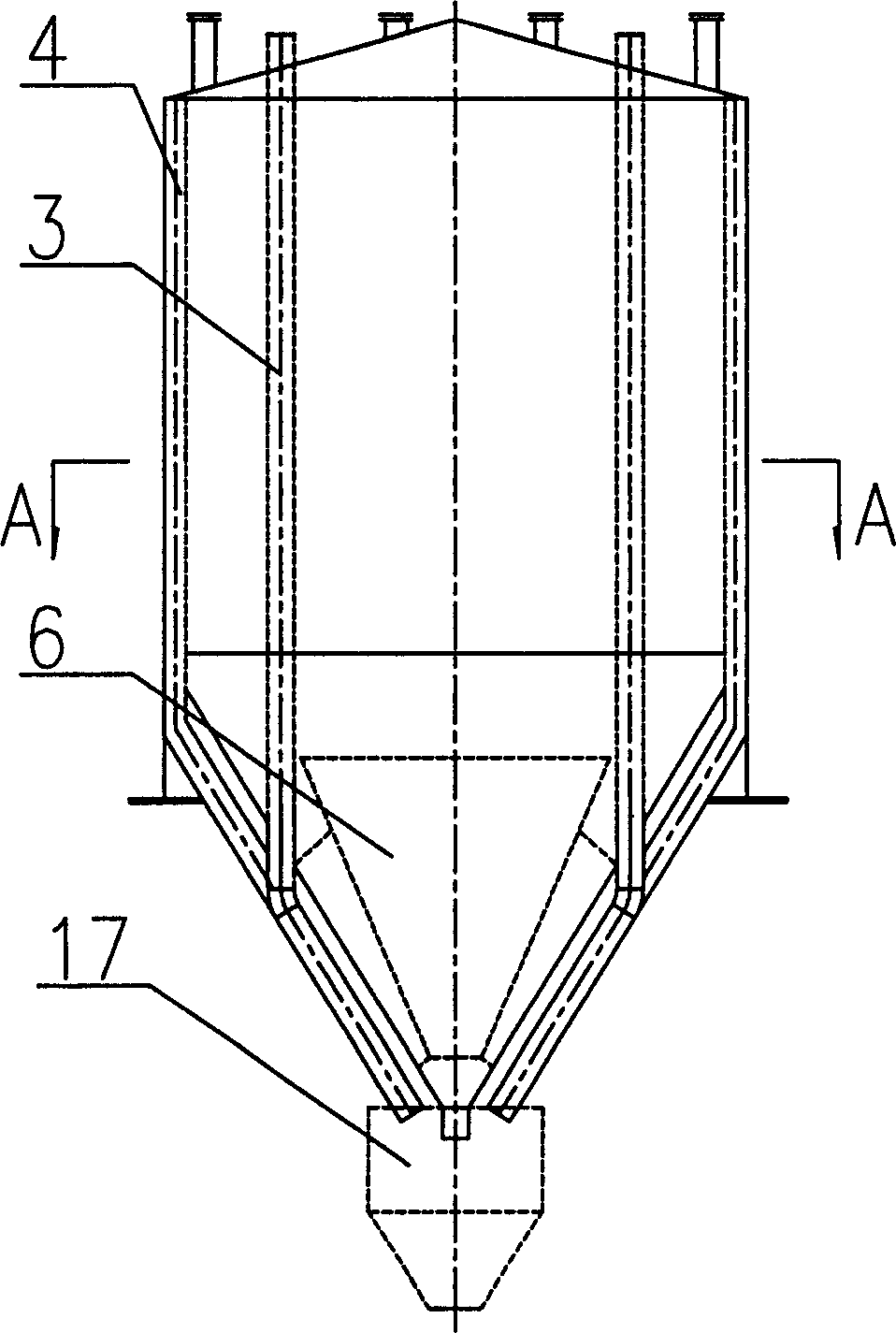

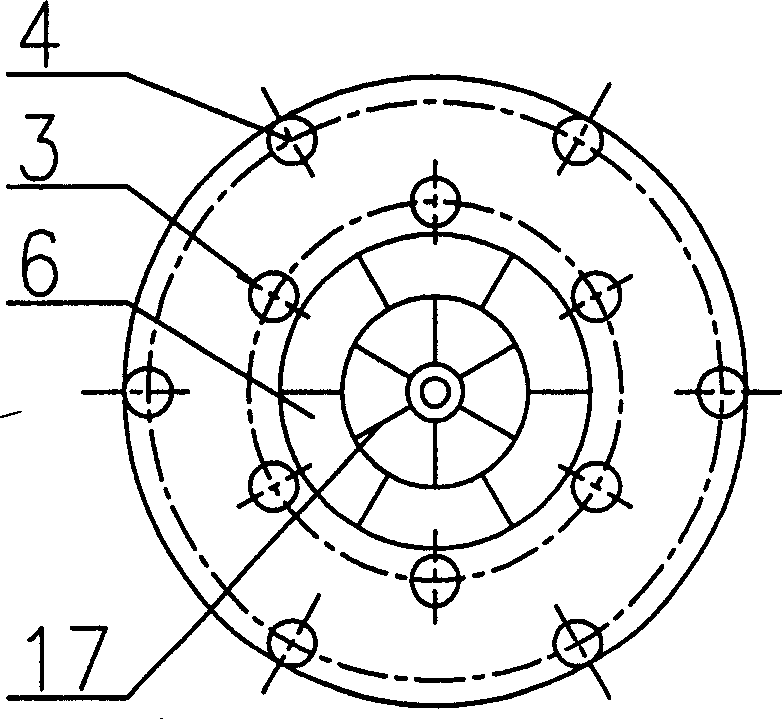

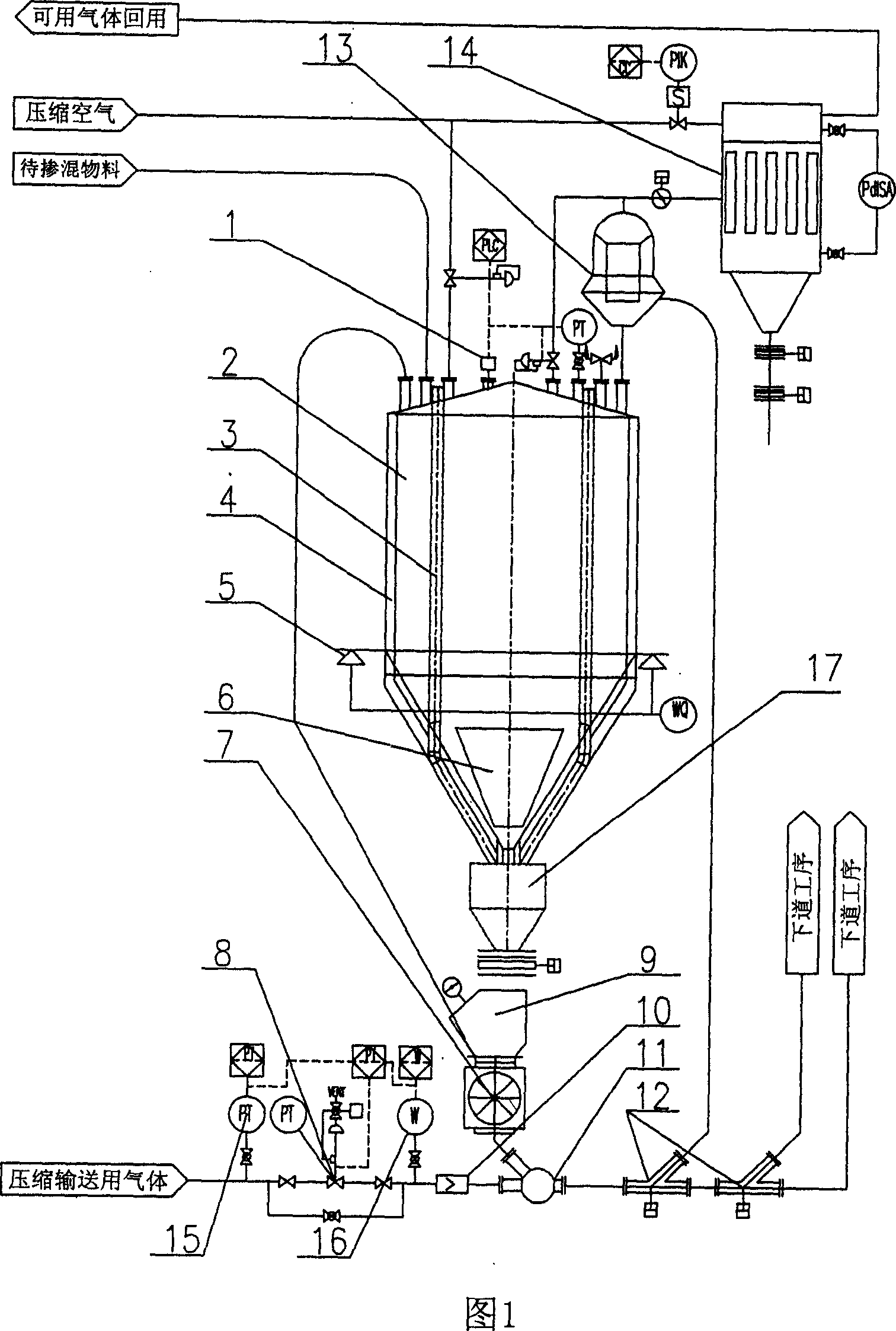

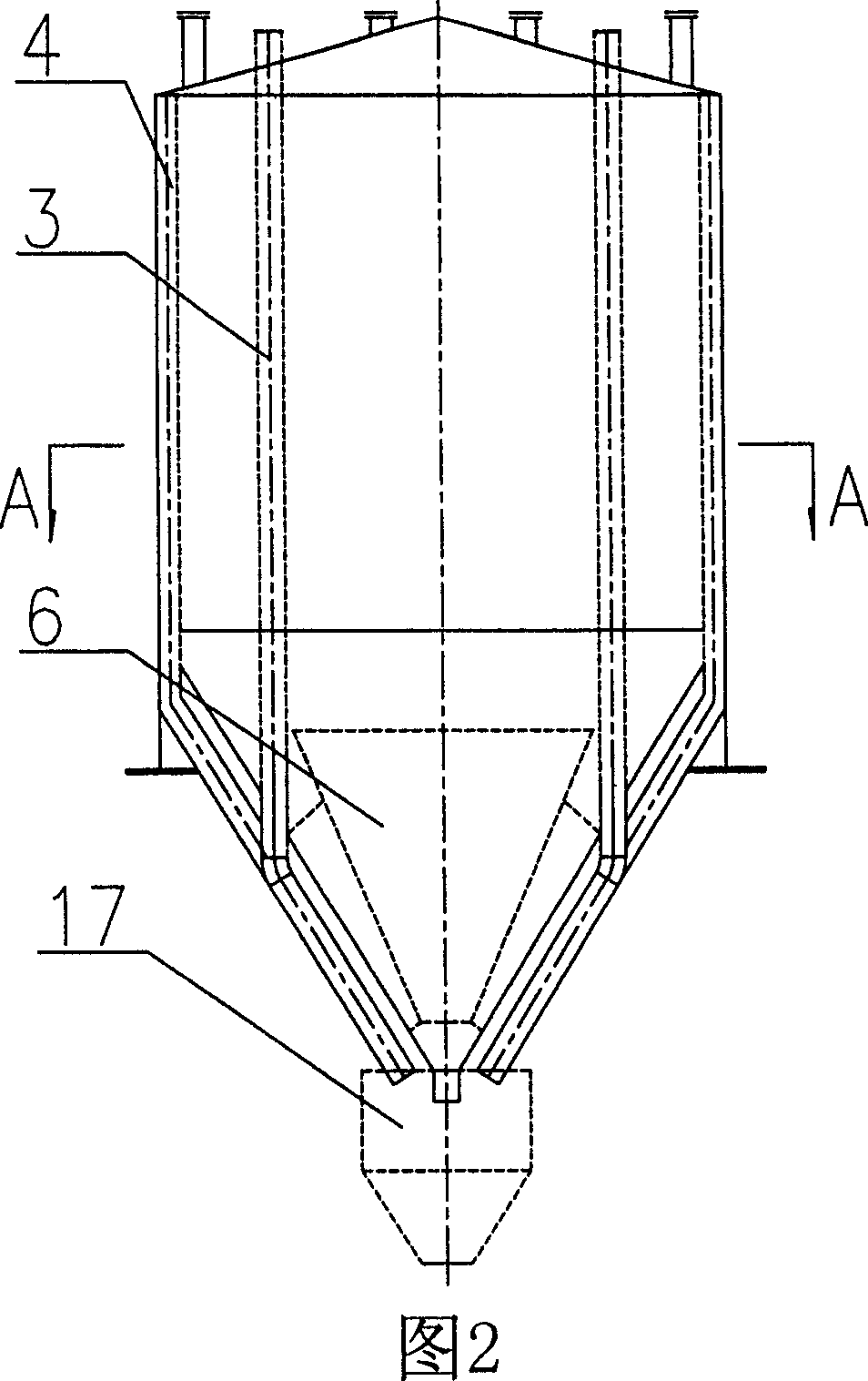

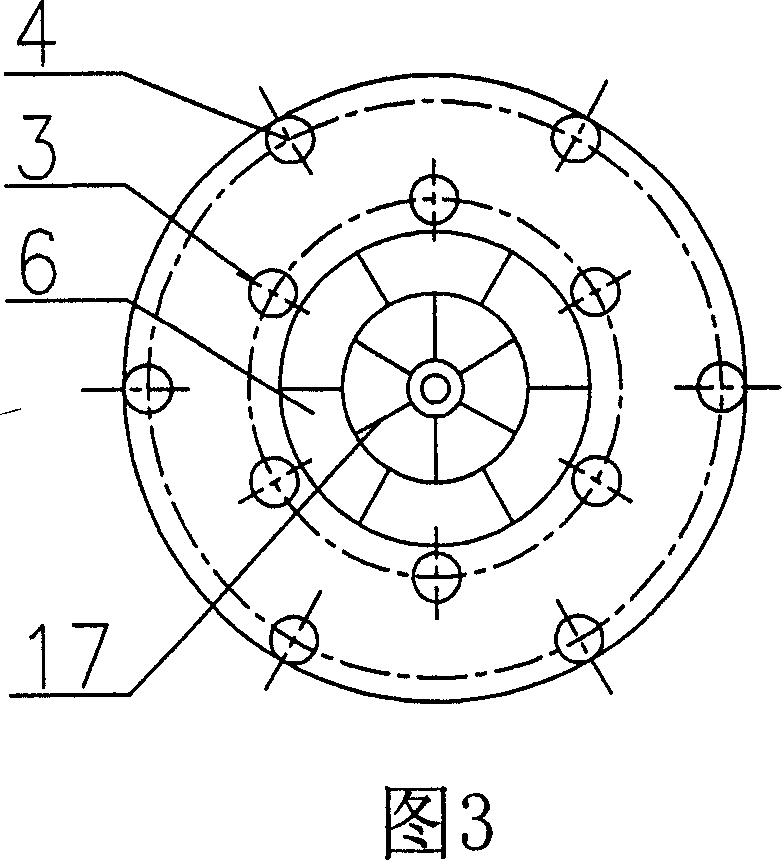

Intelligent energy mixer

InactiveCN1712117AGuaranteed fluidized movementIncrease the mixing ratioFlow mixersTransportation and packagingLine tubingEngineering

An intelligent pneumatic mixer is composed of raw material mixing cabin with multiple central pipes and multiple peripheral pipes close to wall, jet spray pipe, material delivering pipeline, high-pressure feeder, valve for high-pressure delivering pipe, multi-stage multi-conic diffusion separator with volute casing, and high-pressure pulse duster.

Owner:JIANGSU NDZ TECH

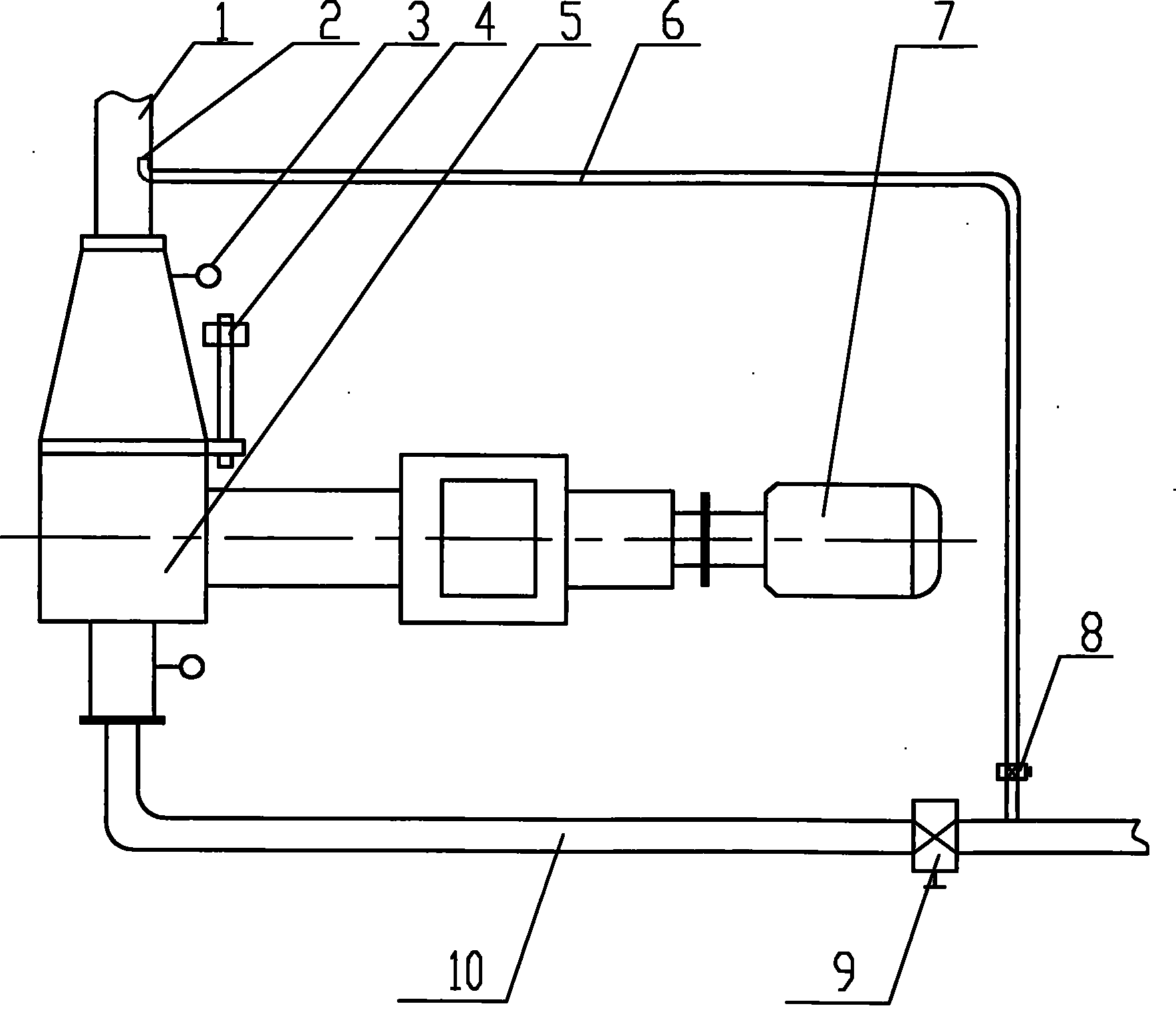

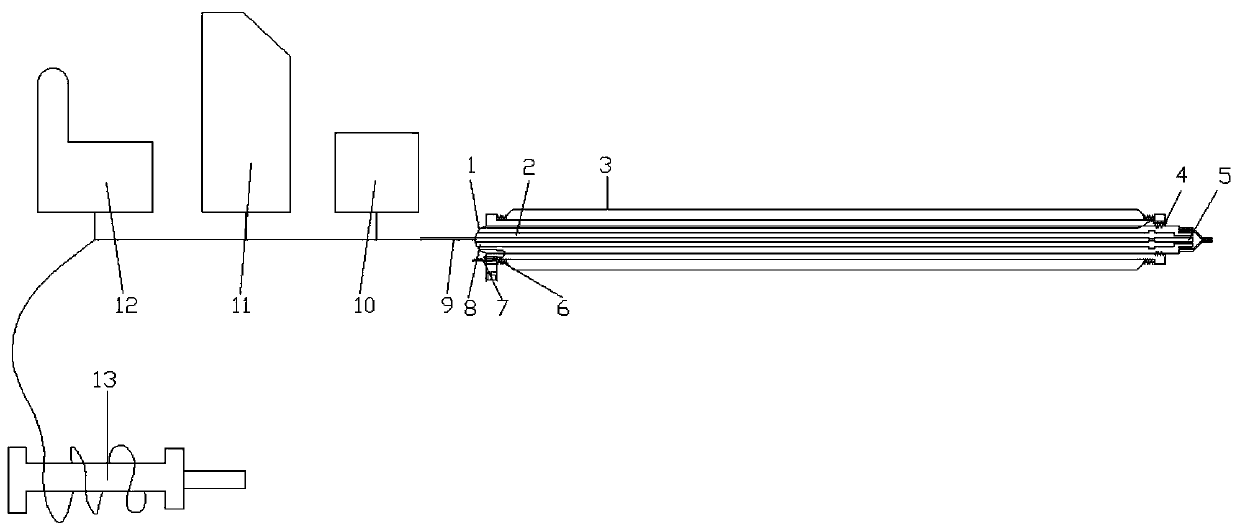

Long-distance wet type concrete spraying method

ActiveCN104265327AAvoid it happening againReduce cloggingUnderground chambersFoundation engineeringSocial benefitsHigh pressure water

The invention relates to a concrete spraying technology. A long-distance wet type concrete spraying method is characterized in that three conveying pipelines including a powdery-accelerating-agent-containing sand gravel conveying pipeline, a cement conveying pipeline and a high-pressure water path are adopted; in the powdery-accelerating-agent-containing sand gravel conveying pipeline, stirred powdery-accelerating-agent-containing sand gravel mixed materials are conveyed into the sand gravel conveying pipeline by a sand gravel conveying device; in the cement conveying pipeline, cement is conveyed into the cement conveying pipeline by a cement conveying device from a cement storage device; the tail end of the cement conveying pipeline is communicated with the sand gravel conveying pipeline and then enters a mixing pipeline; and the high-pressure water path is communicated with a position, with a distance of 0 to 15m from a spray head, on the mixing pipeline. Under the effect of air pressure, the sand gravel materials and the cement are stirred and mixed; the mixing effect is good; the rebounding of spraying materials can be effectively reduced; the occupied space is small; and the limitation of using large-scale stirring and conveying equipment for wet spraying is avoided. The long-distance wet type concrete spraying method has the advantages that the production efficiency is high; the moving is convenient; the maintenance is easy; and economic and social benefits are great.

Owner:河南省煤科院科明机电设备有限公司

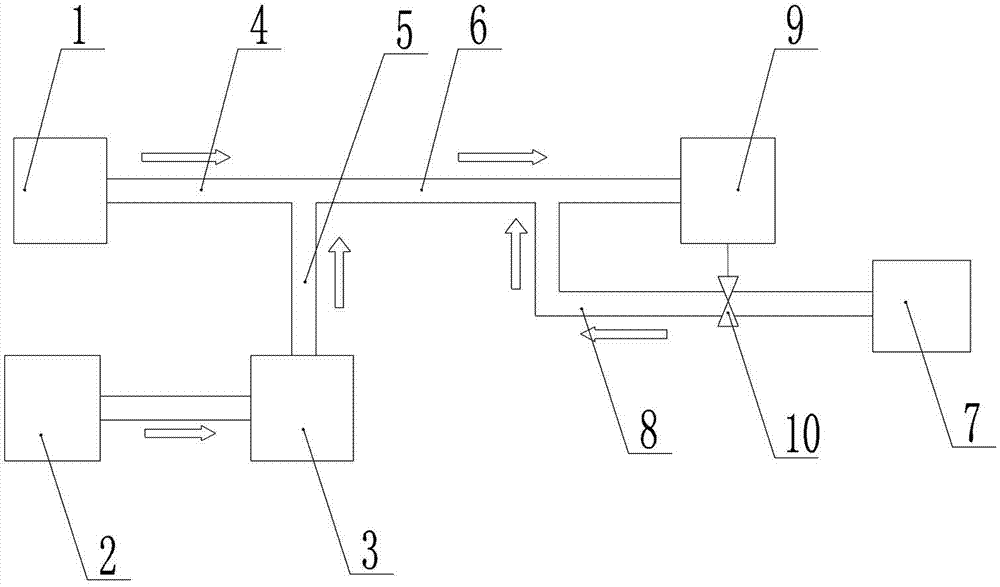

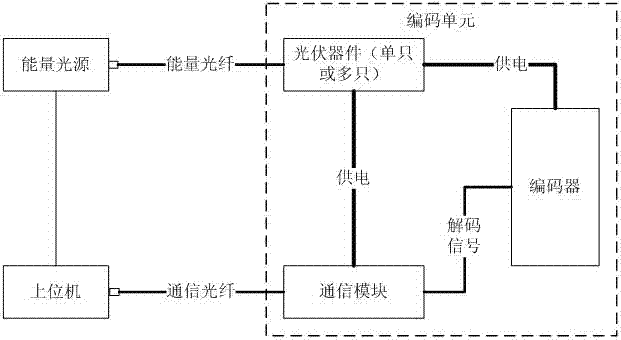

Optical fibre transmission type rotary encoding device

InactiveCN102901522AHigh bandwidthExtend the conveying distanceFibre transmissionConverting sensor outputElectromagnetic interferenceOptoelectronics

The invention discloses an optical fibre transmission type rotary encoding device. The optical fibre transmission type rotary encoding device comprises an energy light source for providing a working energy, an energy optical fibre for transmitting a light source signal provided by the energy light source, an encoding unit for performing energy conversion, decoding processing and communication output based on the light source signal provided by the energy light source, and an upper computer for receiving the communication output signal of the encoding unit and controlling the working of the encoding unit, wherein the energy light source is connected to the encoding unit via an energy optical fibre; and the upper computer is connected to the encoding unit via a communication optical fibre. With the adoption of the optical fibre transmission type rotary encoding device disclosed by the invention, defects such as incapacity of being used in occasions with a high-insulation requirement in the prior art can be overcome; and the optical fibre transmission type rotary encoding device has the advantages of being capable of being used in occasions with a high-insulation requirement, being far in conveying distance, and high in anti-electromagnetic interference capacity.

Owner:无锡阿斯特科技有限公司

Intelligent energy mixer

InactiveCN1313192CGuaranteed fluidized movementIncrease the mixing ratioFlow mixersBulk conveyorsLine tubingHigh pressure

An intelligent pneumatic mixer is composed of raw material mixing cabin with multiple central pipes and multiple peripheral pipes close to wall, jet spray pipe, material delivering pipeline, high-pressure feeder, valve for high-pressure delivering pipe, multi-stage multi-conic diffusion separator with volute casing, and high-pressure pulse duster.

Owner:JIANGSU NDZ TECH

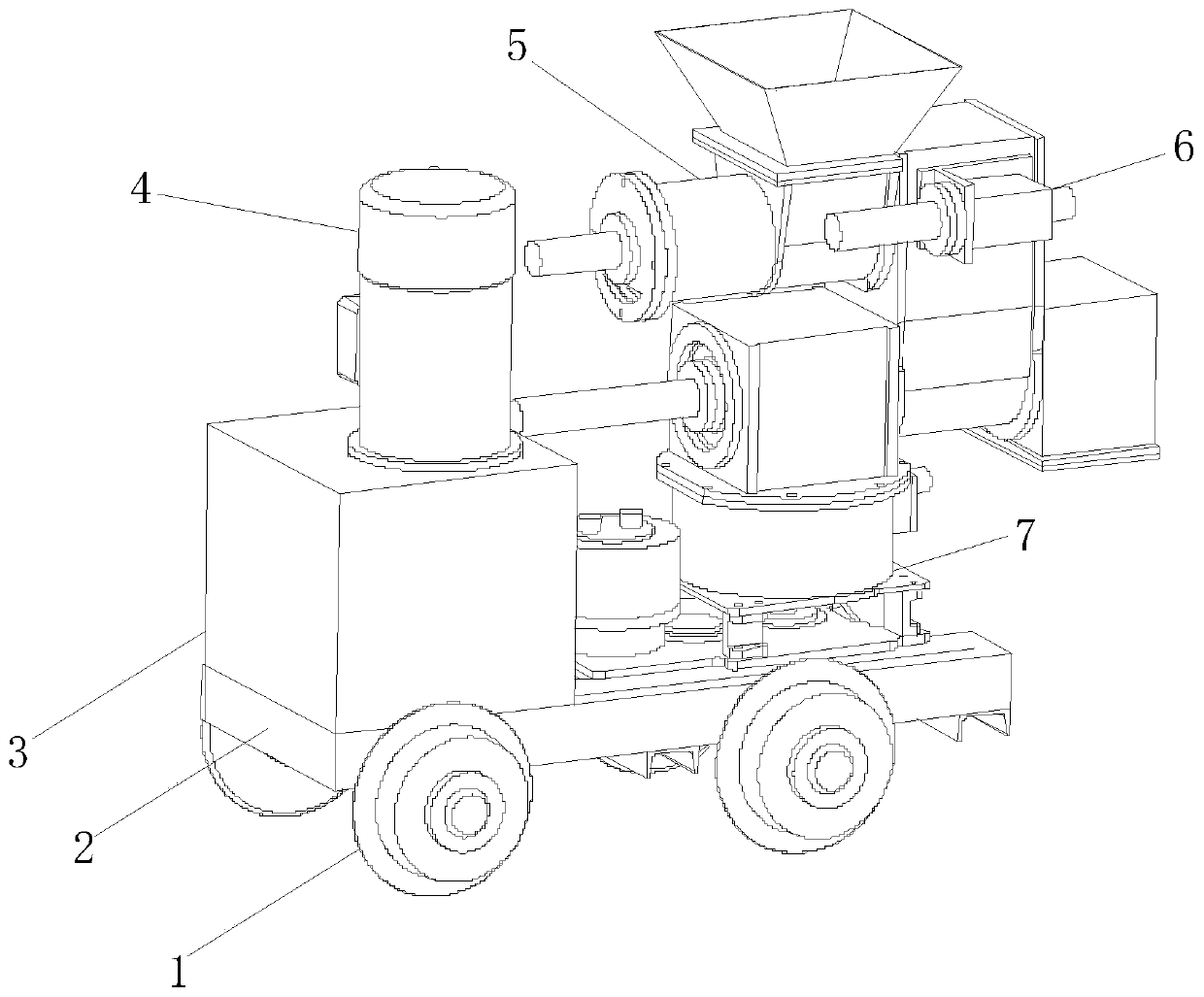

Long-distance pulverized coal conveying equipment

The invention discloses long-distance pulverized coal conveying equipment, which comprises a screw conveying pump, a pulverized coal conveying pipe connected with the front end of the screw conveying pump and an air pipe connected with the rear end of the screw conveying pump. The key technique of the equipment is that an auxiliary air pipe, of which one end is communicated with the air pipe through a ball valve or a stop valve and the other end is communicated with the pulverized coal conveying pipe through an arranged elbow, is arranged between the pulverized coal conveying pipe and the air pipe. The equipment requires small investment and floor area, operates smoothly and can convey a large amount of pulverized coal and realize long-distance pulverized coal conveying.

Owner:XINXING DUCTILE IRON PIPES CO LTD

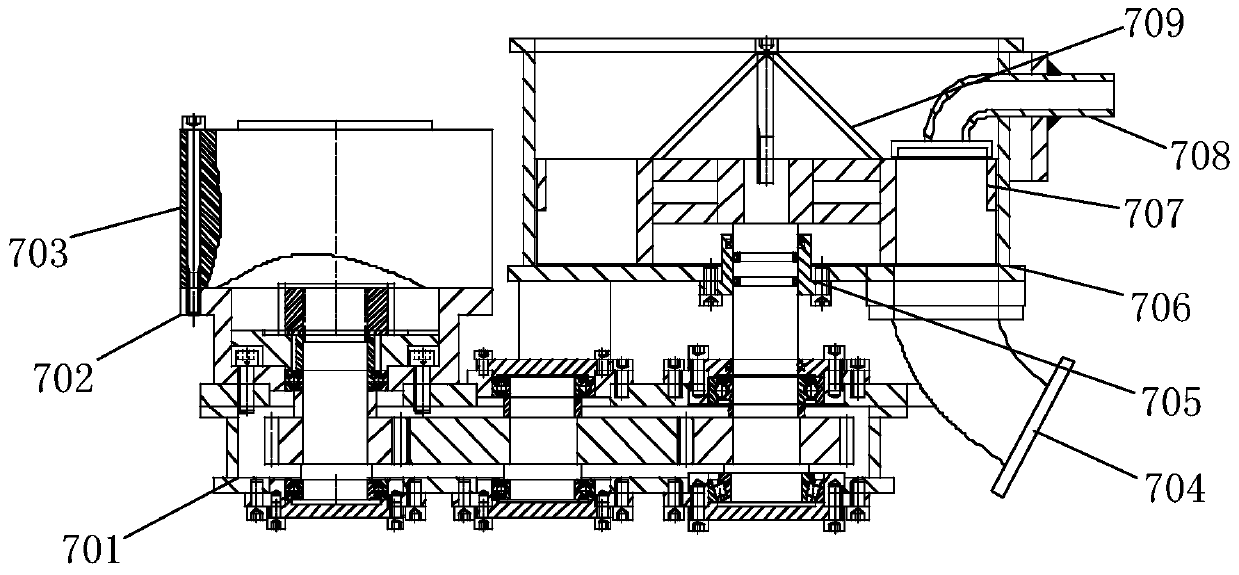

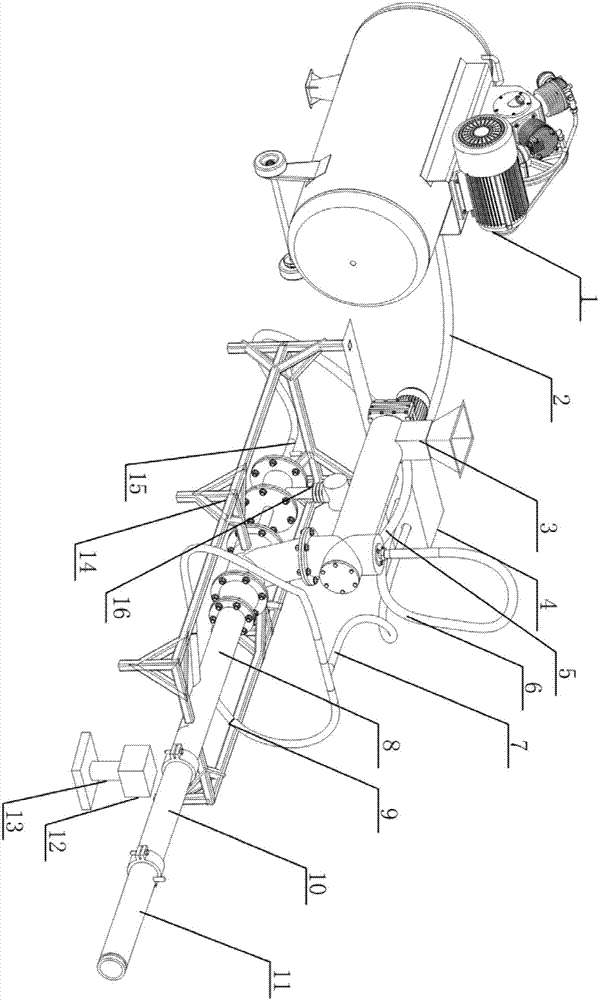

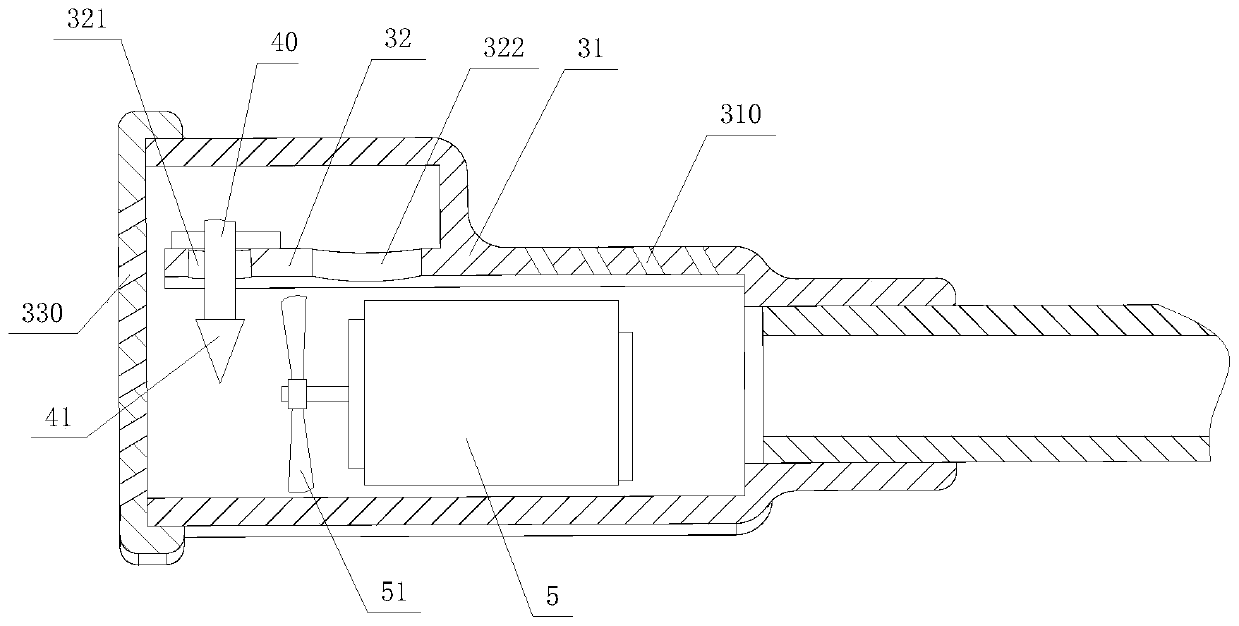

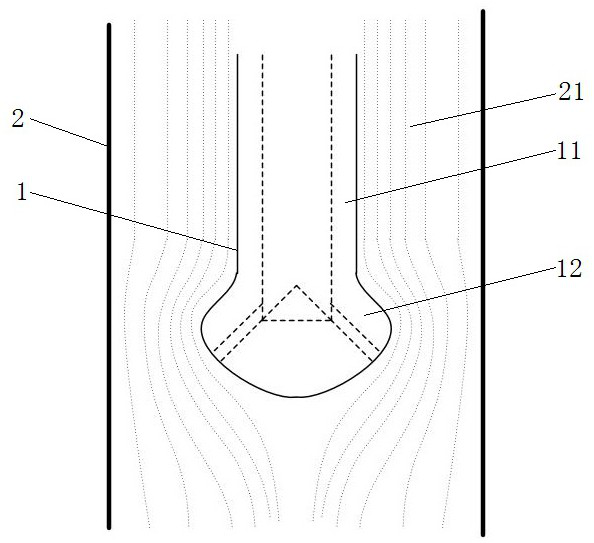

Long-distance concrete sprayer

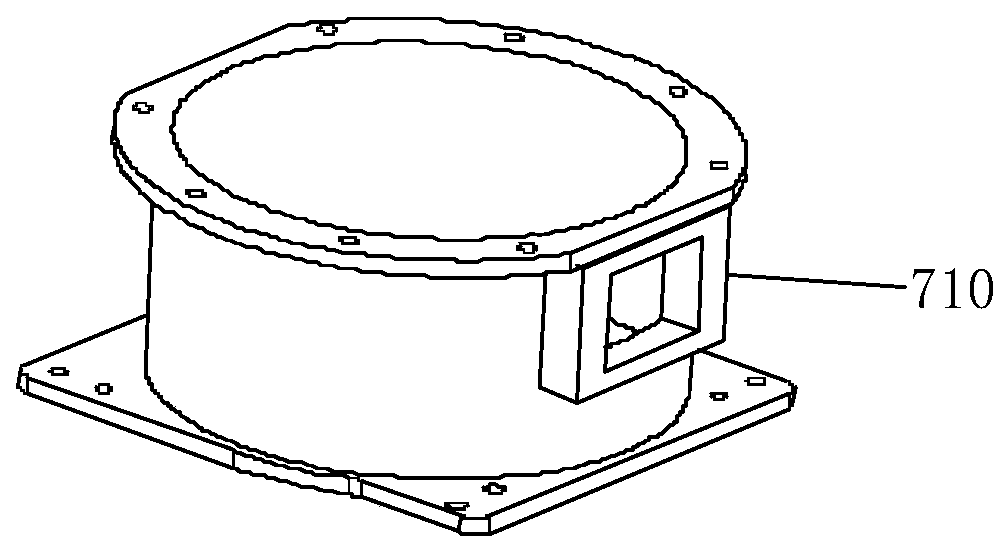

ActiveCN111188637ACompact structureImprove sealingUnderground chambersLift valveSprayerElectric machine

The invention provides a long-distance concrete sprayer and relates to the technical field of concrete spraying equipment. The long-distance concrete sprayer comprises an underframe, a cylinder barrelmechanism, a rotor mechanism and a hydraulic system. The cylinder barrel mechanism comprises an upper cylinder barrel part and a lower cylinder barrel part. The cylinder barrel, a pushing piston, a sealing piston and a sealing box body of the sealing piston are matched one another, the sealing piston and the cylinder barrel form an end surface seal and a material collecting box is arranged on theend part of the lower cylinder barrel for collecting excess materials accumulated by the pushing piston. The rotor mechanism primarily comprises a rotor shell, a rotor and a cone-shaped distributor,and in a rotating process of the rotor, materials in stock bins are sprayed continuously. The hydraulic system comprises a hydraulic fuel tank and a motor and provides power to the sprayer. The sprayer in a form of end surface seal avoids friction between the sealing part and concrete and the cylinder barrel. The pushing piston can be a rigid piston which achieves sealing by means of the sealing piston. The rotor mechanism distributes the concrete uniformly to achieve pulse-free continuous spraying. The long-distance concrete sprayer also has the advantages of long-distance dust-free conveyance, being in long in service life and the like.

Owner:SHANDONG UNIV OF SCI & TECH

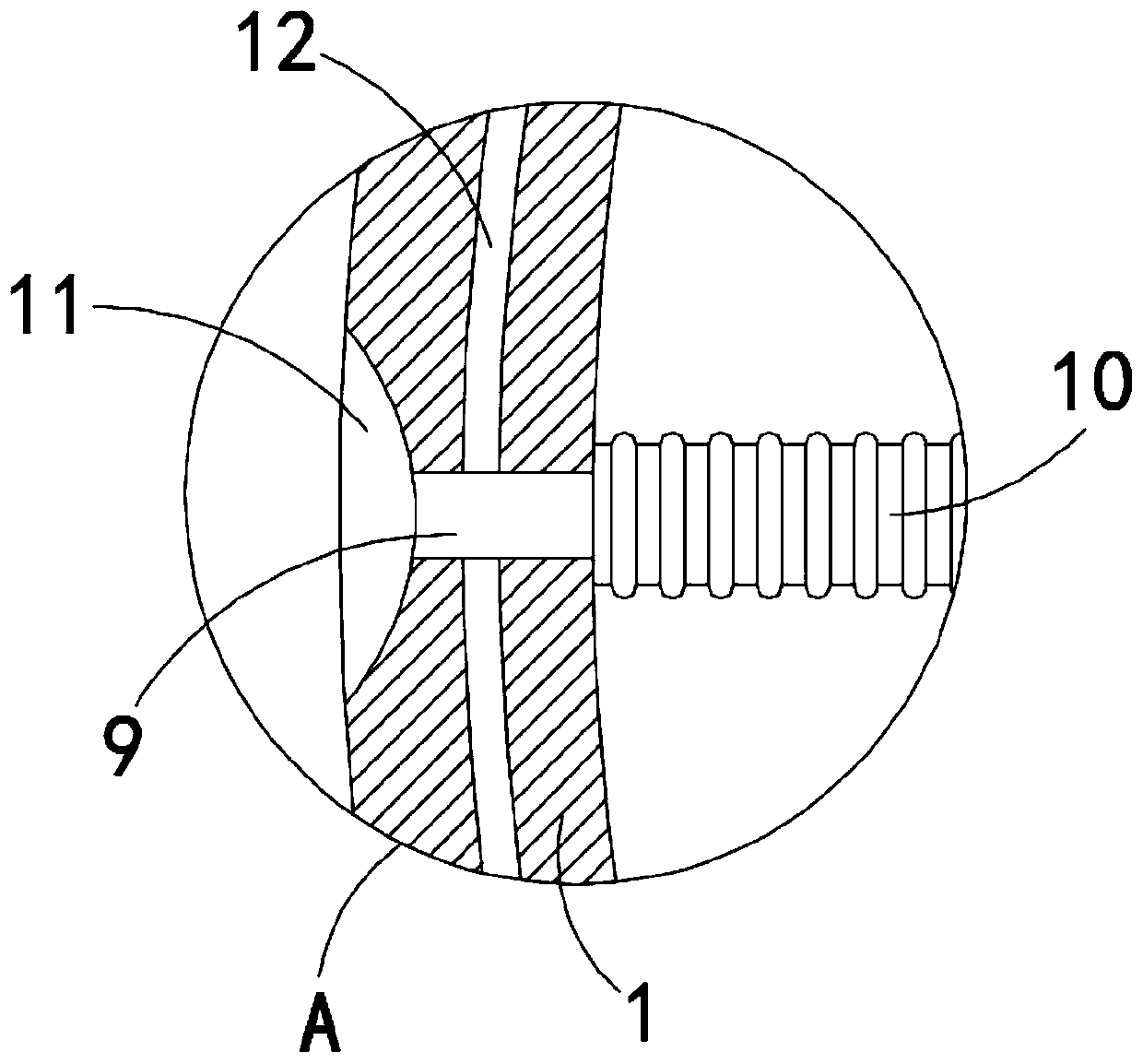

Multi-channel optical cable bundling tube

ActiveCN109581604AReduce frictionExtend the conveying distanceFibre mechanical structuresOptical fibre/cable installationLubricationEngineering

The invention belongs to the field of bundling tubes, and particularly relates to a multi-channel optical cable bundling tube. The multi-channel optical cable bundling tube comprises a protecting sleeve, a solid cylindrical body is arranged in the protecting sleeve, a reinforcing cavity is formed in the center of the solid cylindrical body in the axial direction of the solid cylindrical body, a tensile tube is arranged in the reinforcing cavity, a plurality of optical cable storing cavities are evenly distributed around the reinforcing cavity, a lubrication cavity is formed between every two adjacent optical cable storing cavities, the lubrication cavities communicate with the optical cable storing cavities through a plurality of liquid delivery channels, the lubrication cavities are filled with lubricants used for reducing friction force between optical cables and the optical cable storing cavities, reinforcing tubes are fixedly connected to the side walls, away from the reinforcing cavity, of the lubrication cavities, the other ends of the reinforcing tubes penetrate out of the solid cylindrical body in the radial direction of the solid cylindrical body, and the protecting sleeveis provided with a communicating tube corresponding to the reinforcing tube in position. The multi-channel optical cable bundling tube is provided with the lubrication cavities, the lubricants can overflow in the whole process, the friction force between the optical cables and the optical cable storing cavities is reduced, the delivery distance is increased, and thus the laying efficiency is improved.

Owner:武汉齐力得管业有限公司

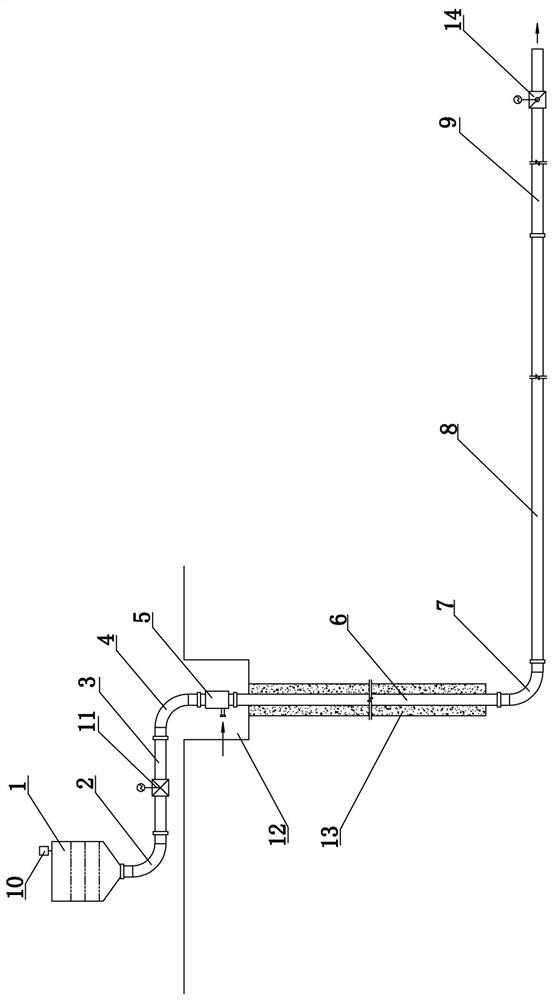

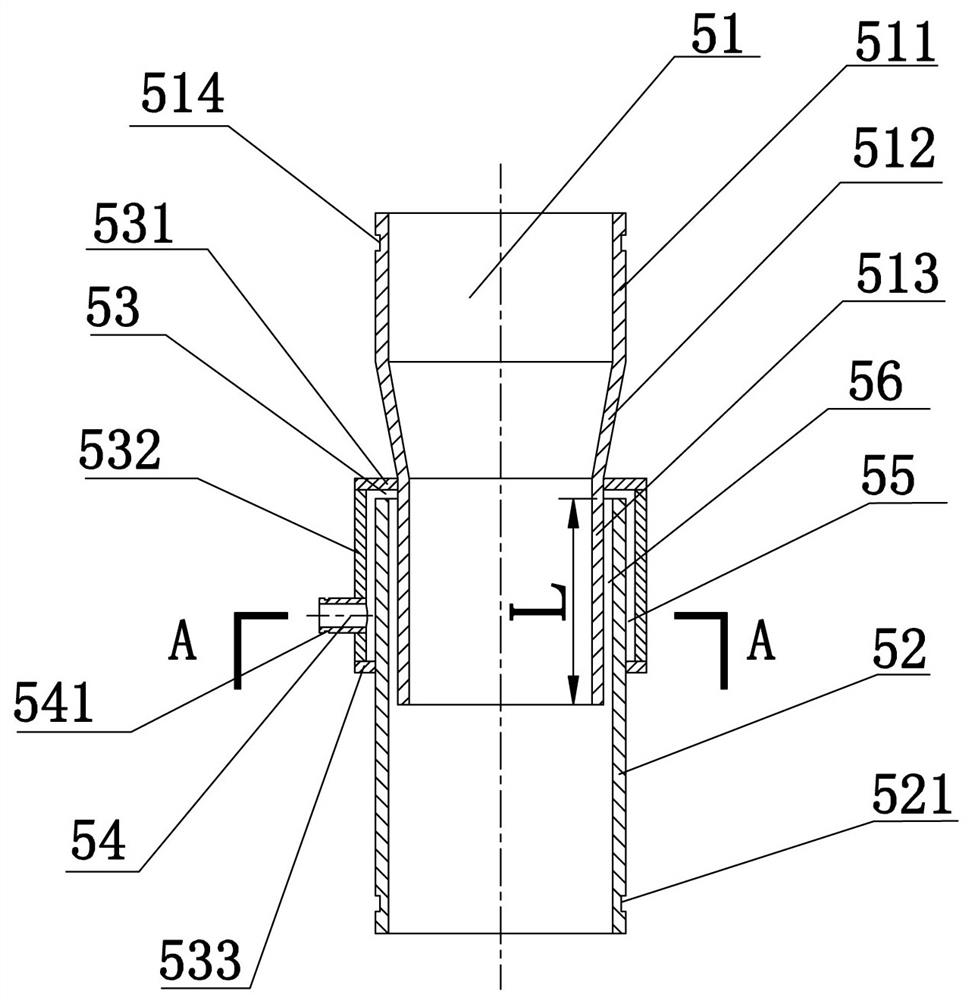

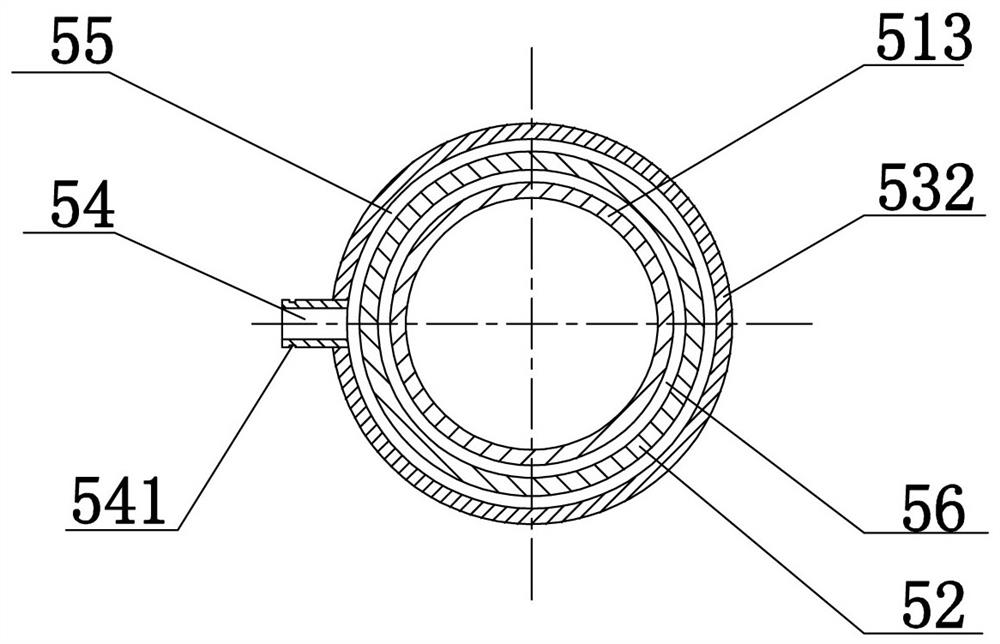

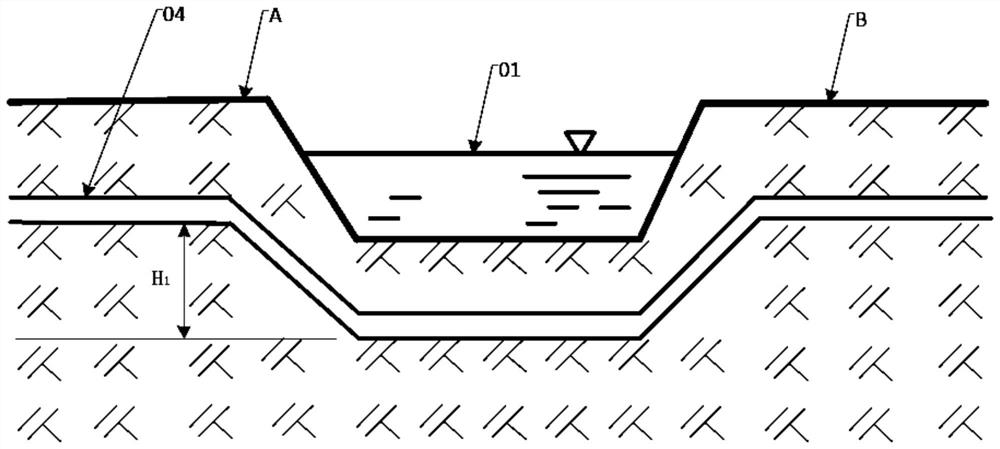

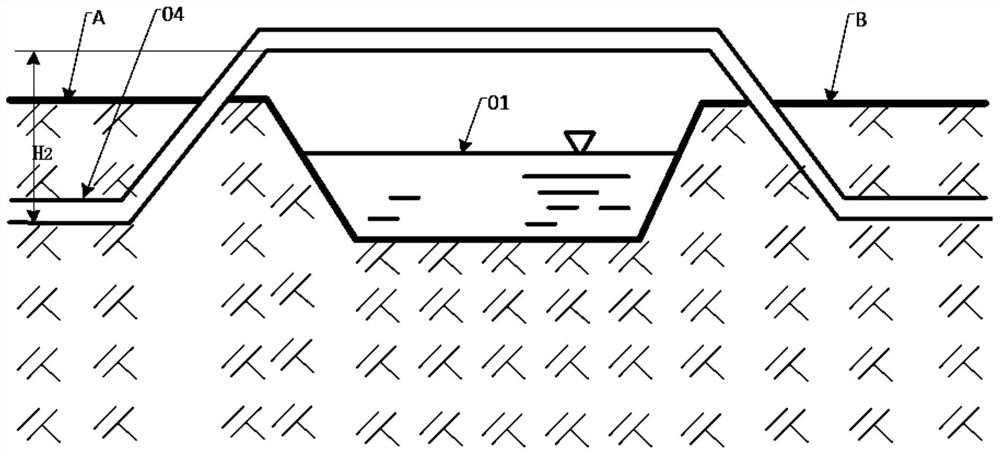

Filling slurry low-resistance free-flow pipeline conveying system

PendingCN111981209AMake full use of gravitational potential energyHigh concentricityPipeline systemsFlexible pipesAutomatic controlControl system

The invention relates to a filling slurry low-resistance free-flow pipeline conveying system which comprises a receiving hopper, a filling guide pipe, a filling vertical pipe, an underground filling pipeline and an automatic control system. The filling slurry low-resistance free-flow pipeline conveying system is characterized in that the receiving hopper is arranged corresponding to a discharge hole of a stirring device; a liquid level monitoring device is arranged on the receiving hopper; a water ring damping device is arranged at the upper end of the filling vertical pipe; one end of the filling guide pipe communicates with a discharge hole of the receiving hopper; the other end of the filling guide pipe communicates with the feed end of the water ring damping device; a motor switch valve is arranged on the filling guide pipe; the underground filling pipeline is arranged in a main roadway and a branch roadway and is suspended on top plates of the roadways; the lower end of the filling vertical pipe communicates with the starting end of the underground filling pipeline; the tail end of the underground filling pipeline extends to an underground goaf to be filled; and an electric adjusting valve is arranged at the position close to the tail end of the underground filling pipeline. The filling slurry low-resistance free-flow pipeline conveying system has the advantages that the structure design is simple and reasonable, the gravitational potential energy is fully played, the on-way resistance and the local resistance of pipeline conveying is reduced, and the conveying distance is lengthened.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

High polymer deep hole positioning self-enclosed slurry nozzle and slurry system and method thereof

PendingCN111119158AExtend the slurry conveying distanceExtend the conveying distanceMarine site engineeringTunnelsPhysicsEngineering

The invention discloses a high polymer deep hole positioning self-enclosed slurry nozzle and a slurry system and method thereof. The slurry nozzle comprises a nozzle body the inside of which is hollow; a conveying tube for conveying slurry is arranged inside the hollow cavity; the exit end of the nozzle body is provided with a nozzle; the conveying tube is inserted into the nozzle body from the feeding end of the nozzle body and extends to the exit end of the nozzle body where the conveying tube is connected with the nozzle; the nozzle body is covered with a sealed air bag which is equipped with an inflatable port from where the sealed air bag can be inflated and clinging to the hole wall so as to to achieve sealed slurry; and the nozzle body is also fixed with a first camera for detectingthe location of diseases and a second camera to monitor whether the slurry is saturated. The invention also provides a slurry system and method of the high polymer deep hole positioning self-enclosedslurry nozzle. According to the invention, long-distance transport can be realized, and the deep hole positioning layer-by-layer self-enclosed slurry can meet the requirements of high polymer slurry,and is especially suitable for the construction condition of deep hole and multi-layer disease disposal.

Owner:郑州维霖工程科技有限公司 +1

Mining method for jetting concrete in wet type

ActiveCN102733823BReduce cloggingAvoid restrictionsUnderground chambersTunnel liningShotcreteMining engineering

The invention relates to a mining method for jetting concrete in a wet type; a method comprises the following steps: preparing cement slurry; stirring gravel mixing material; starting air source to input high pressure air to a gravel mixing material transport pipeline in a jetting procedure; and inputting the cement slurry to a cement slurry transport pipeline through transport equipment; after jetting the cement slurry by a nozzle, adding the gravel mixing material to a jetting machine; under the action of the high pressure air, mixing and stirring the cement slurry and the gravel mixing material; finally, jetting the concrete from the nozzle. According to the invention, the method depends on current jetting equipment; a transport distance (larger than or equal to 60m) of jet concrete is can be increased greatly on a condition of ensuring invariable wet-type concrete jetting advantages; simultaneously, the method effectively avoids problems that large-scale stirring is used hardly and concrete transport equipment is limited under a coal well; production efficiency and jetting quality are improved greatly; in addition, powder dust concentration near the jetting machine is less than or equal to 10mg / m<3>.

Owner:河南省煤科院科明机电设备有限公司

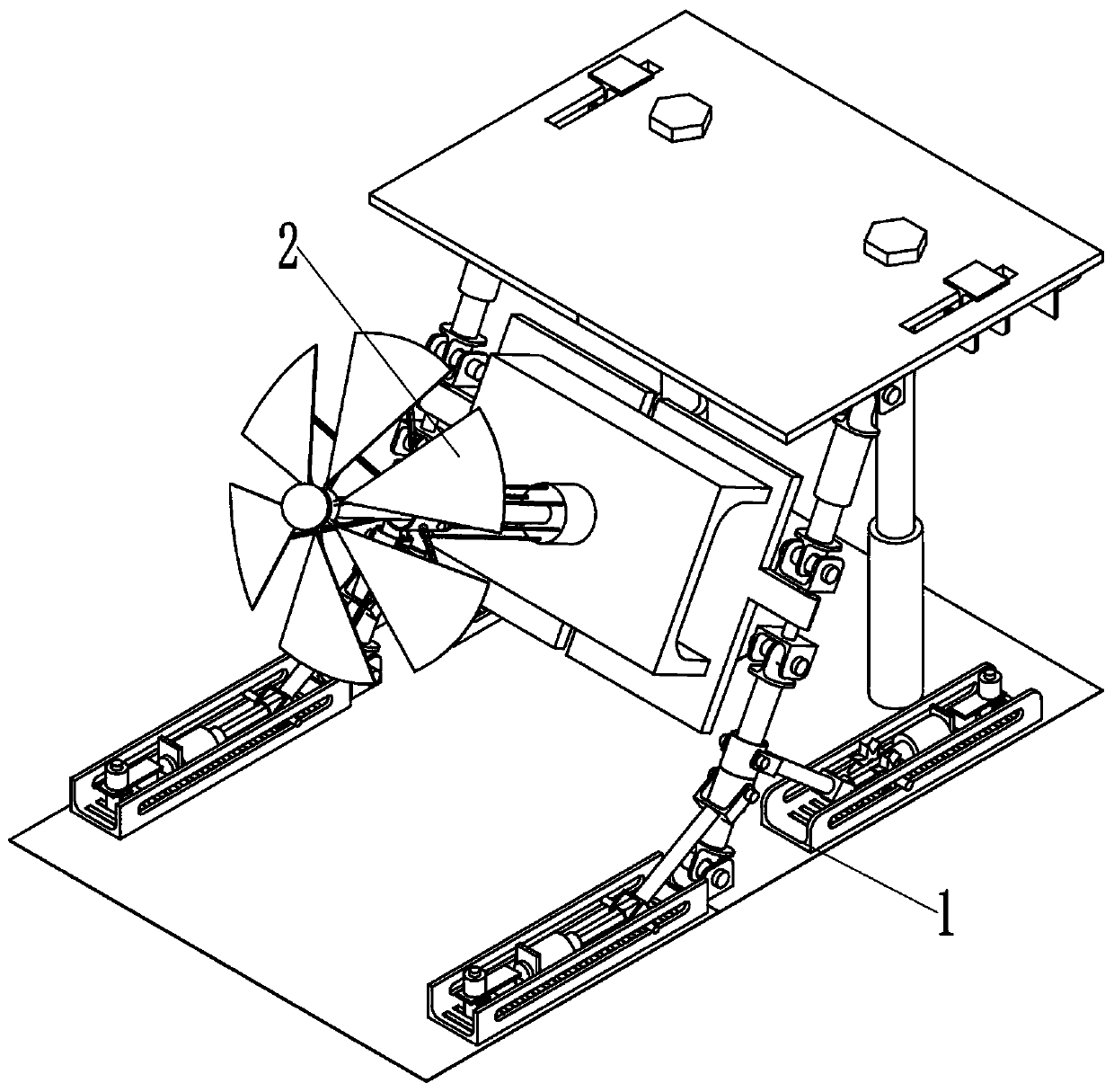

Installation and control method of main and auxiliary machine separation movable radar communication extension set detection device

PendingCN111537970AQuick installation and removalReduce maintenance costsWave based measurement systemsRadarControl engineering

The invention relates to an installation method of a main machine and auxiliary machine separated movable radar communication extension set detection device. The method comprises the steps of firstly,installing a radar supporting device in a cave or a culvert; and then, installing a radar head device on the radar supporting device. The method for installing the radar supporting device in the caveor the culvert comprises the installation steps that firstly, the cave used for radar storage and work is built at the hillside or the hilltop; then, a supporting rack assembly, a hydraulic pump station and a generator set are installed on the ground of the cave; secondly, a supporting lifting driving piece is installed on the supporting rack assembly; thirdly, a supporting lifting top frame is installed on the supporting lifting driving piece; then, a supporting auxiliary swing arm, supporting middle connecting rods and a supporting hinge swing rod are sequentially installed between the supporting lifting top frame and the supporting rack assembly; and then, a support mounting chassis is mounted between the supporting middle connecting rods.

Owner:中国人民解放军32181部队

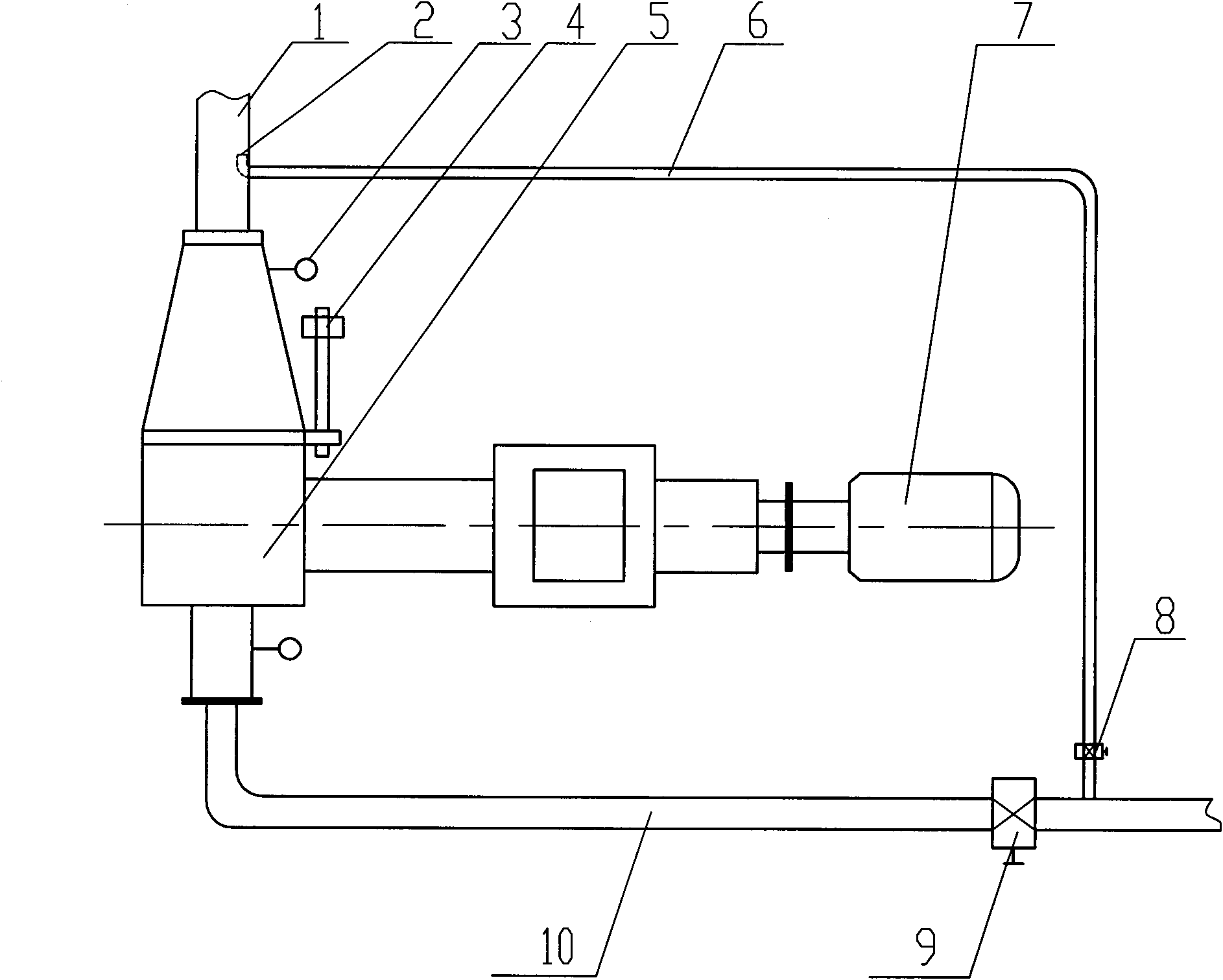

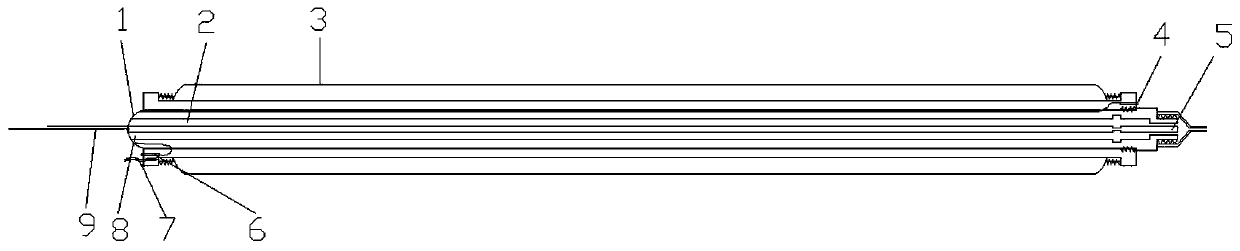

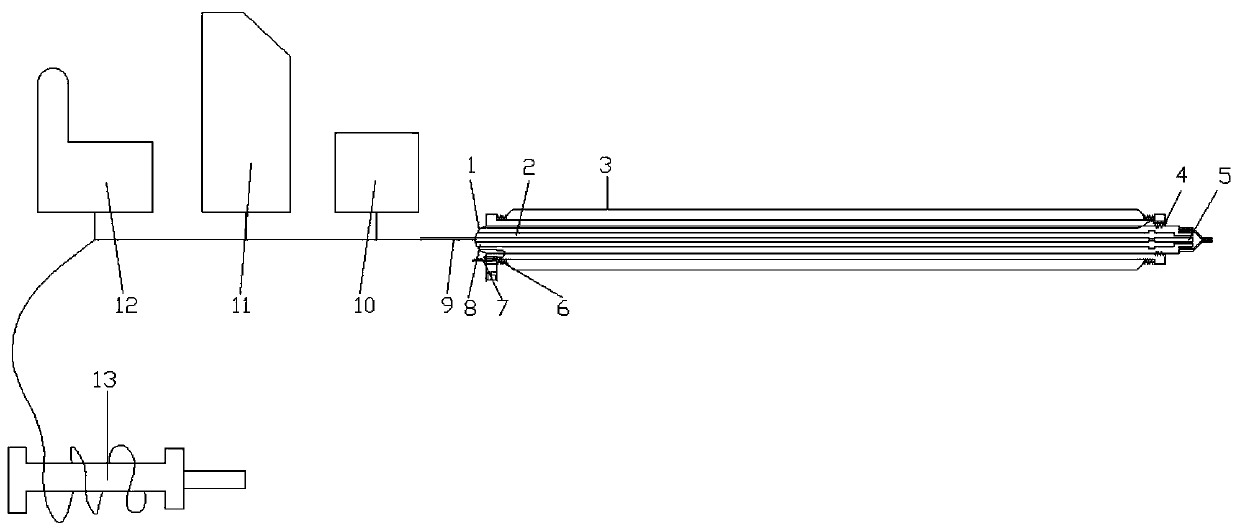

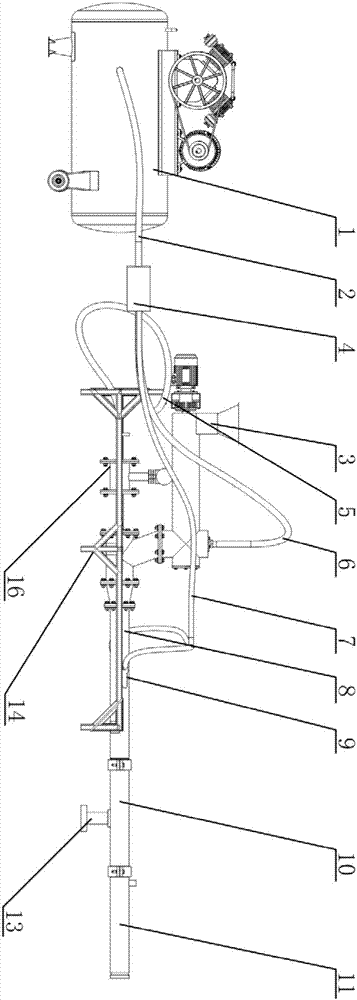

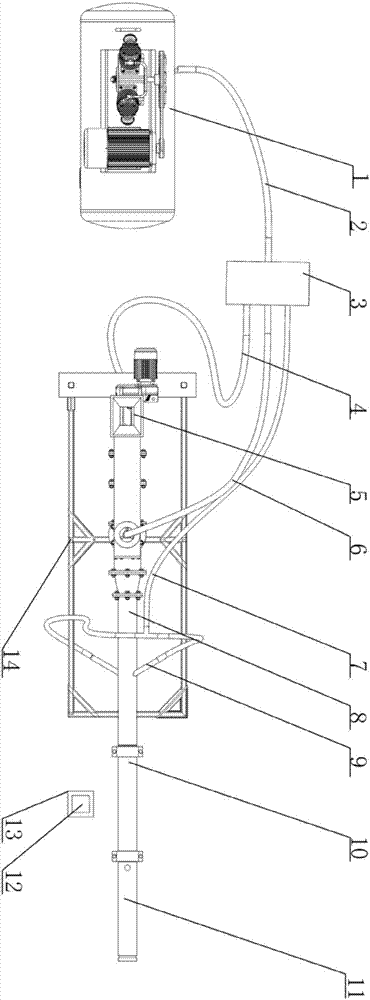

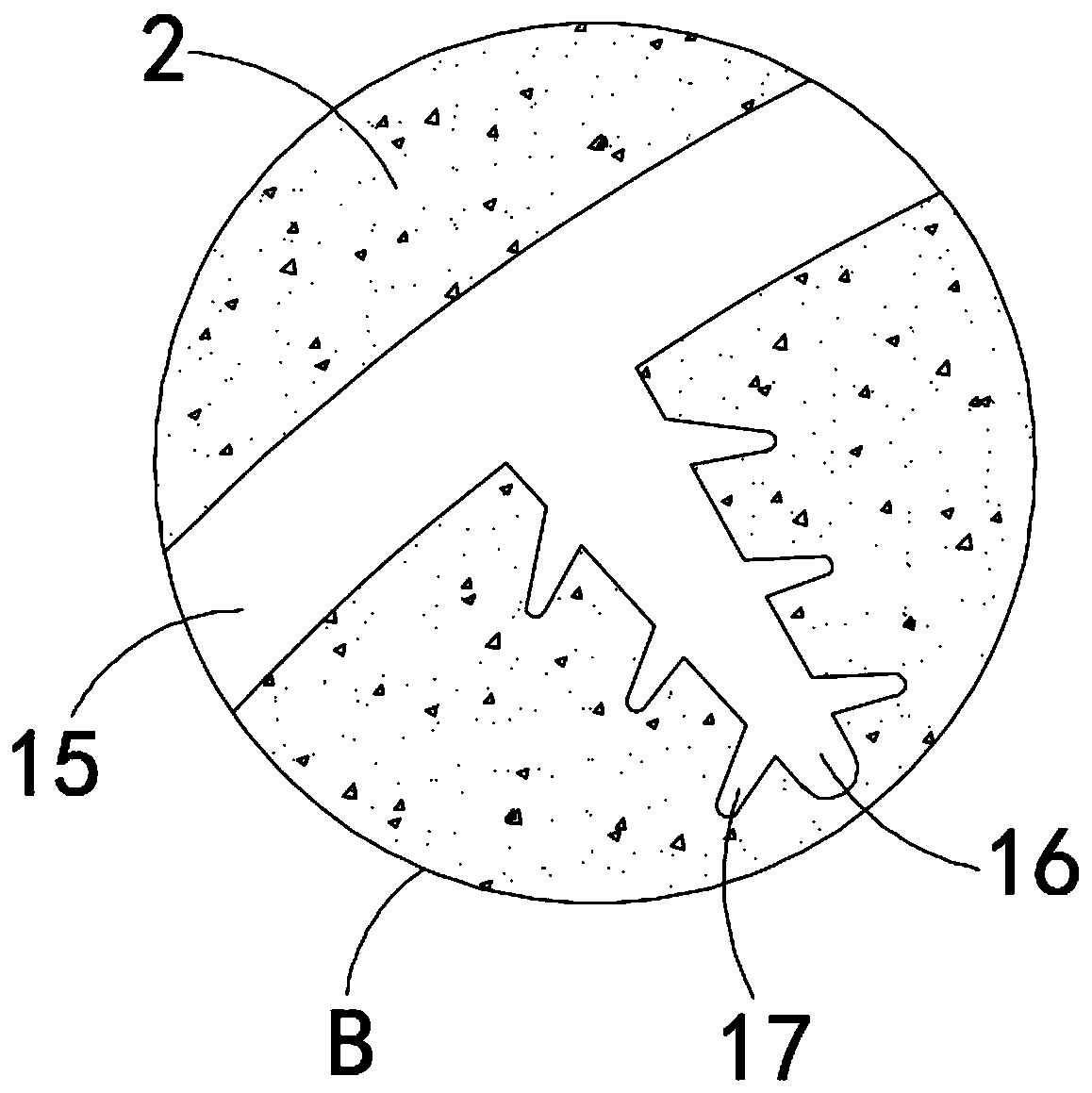

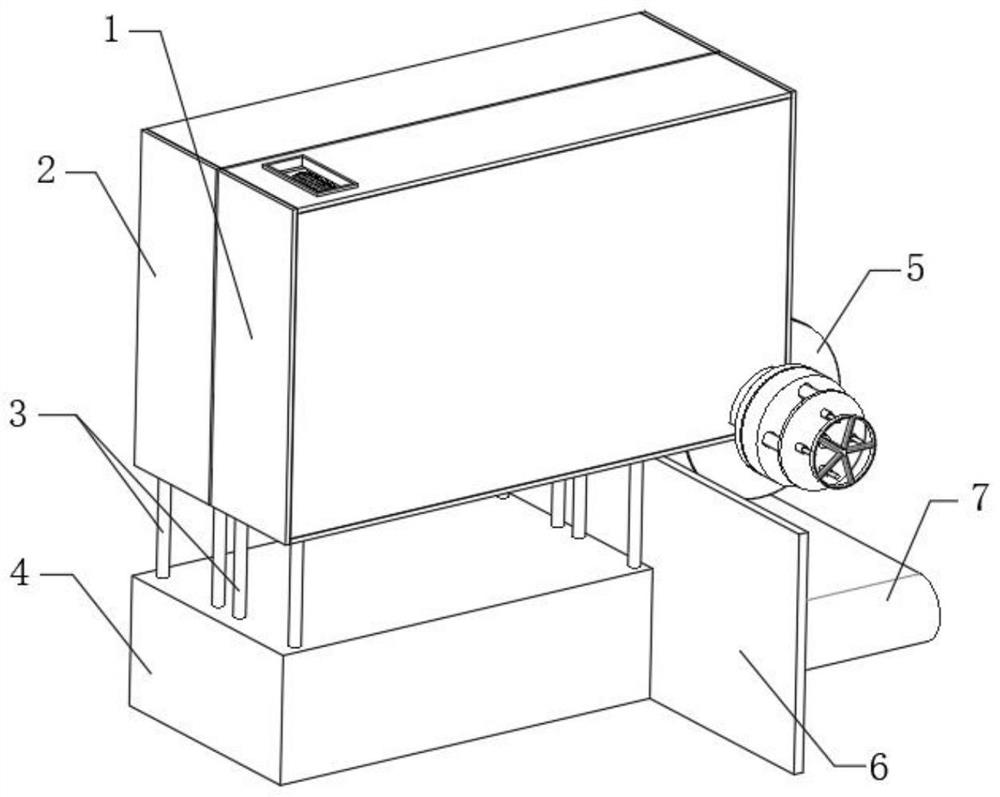

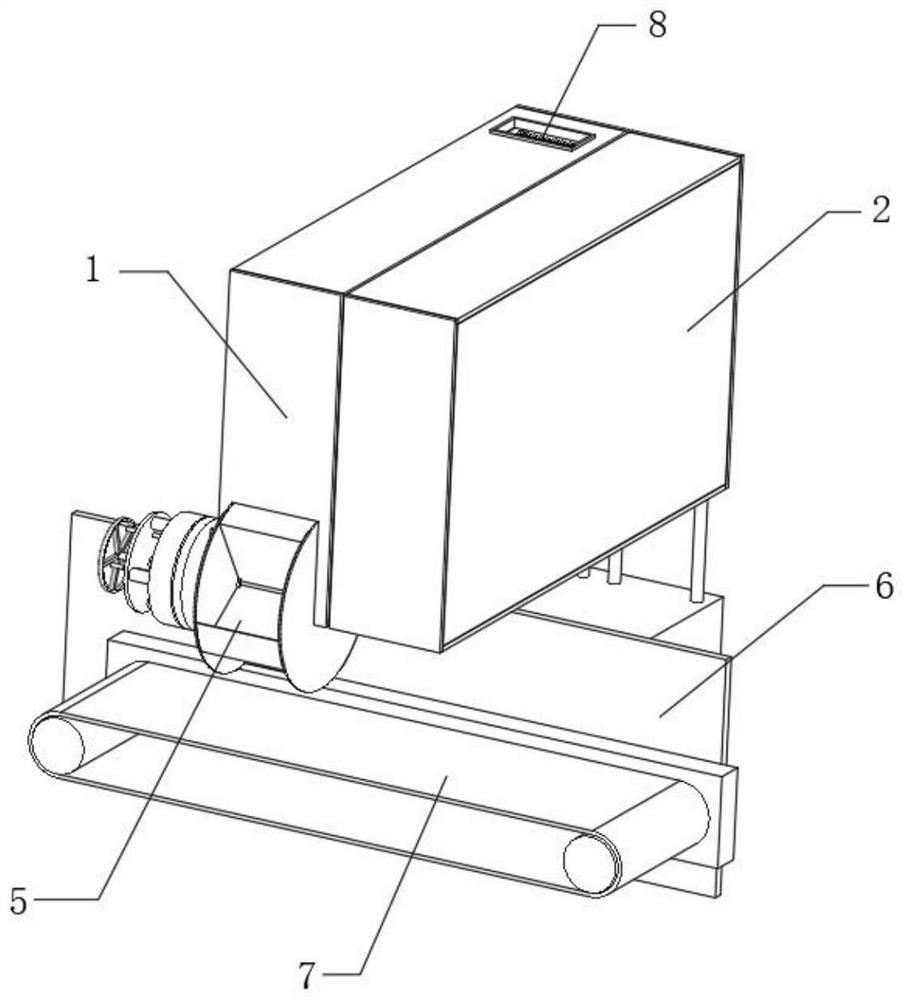

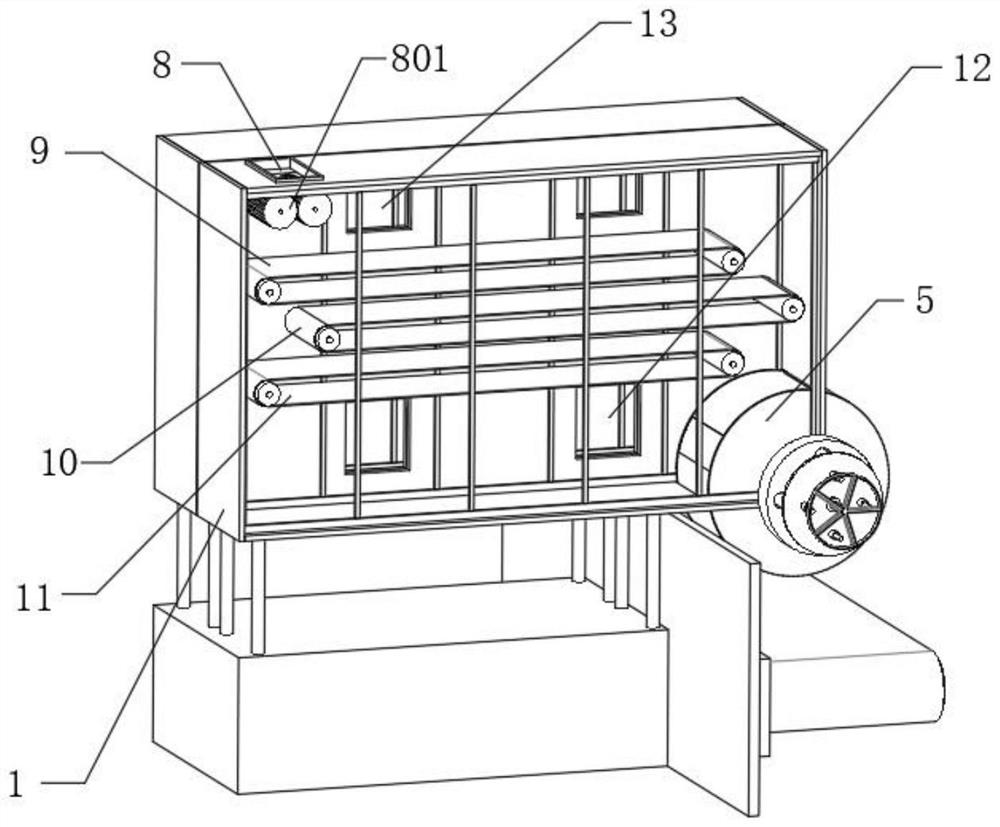

Pneumatic jet performance test bench

The invention discloses a pneumatic jet performance test bench comprising an air compressor (1), a main air duct (2), a spiral feeding device (3), a proportional flow valve (4), a main conveying duct (5), a positive pressure air duct (6), a swirl air duct (7), a pneumatic injector (8), a swirling auxiliary duct (9), a transparent conveying pipe (10), a straight conveying pipe (11), a high speed camera (12) , a camera stand (13), a support frame (14), an anemostat (15) and a vortex flowmeter (16). The test bench can use a multi-index orthogonal test scheme to study the influence rules of structural parameters of a pneumatic injector and the distribution ratio of different air flows on the jetting performance. By recording the pressure change of an internal flow field and the material transportation situation of an injection system under the combination of different parameters, the best injector parameters according with the actual working conditions are obtained, the efficiency of the pneumatic injector is improved, the reliability of a pneumatic conveying system is ensured, and pipe clogging and other accidents are reduced.

Owner:CHINA UNIV OF MINING & TECH

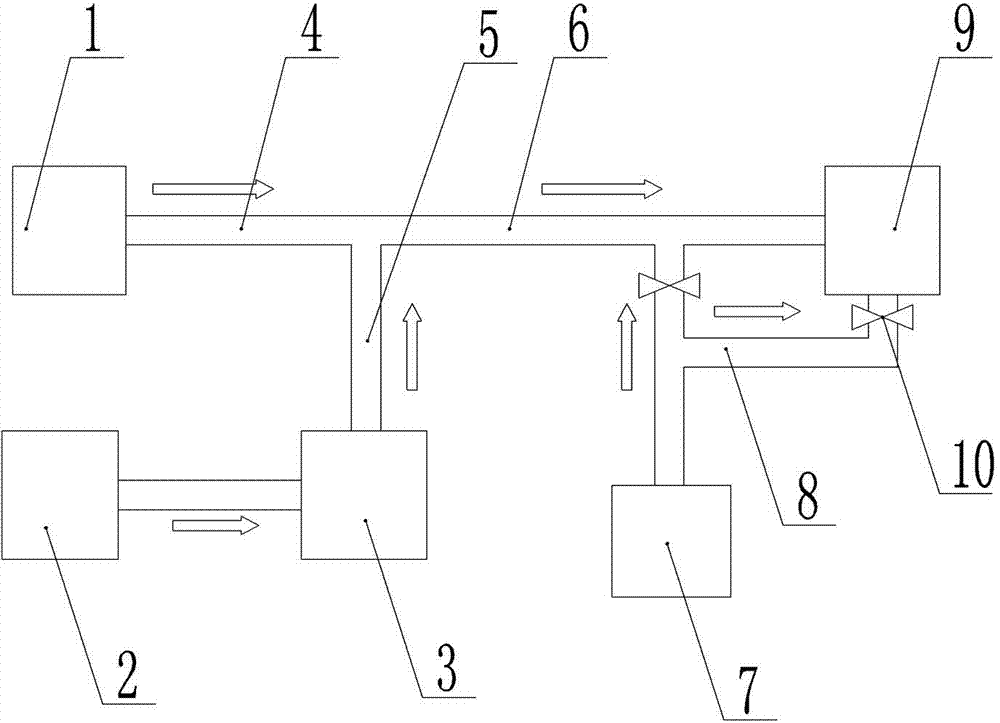

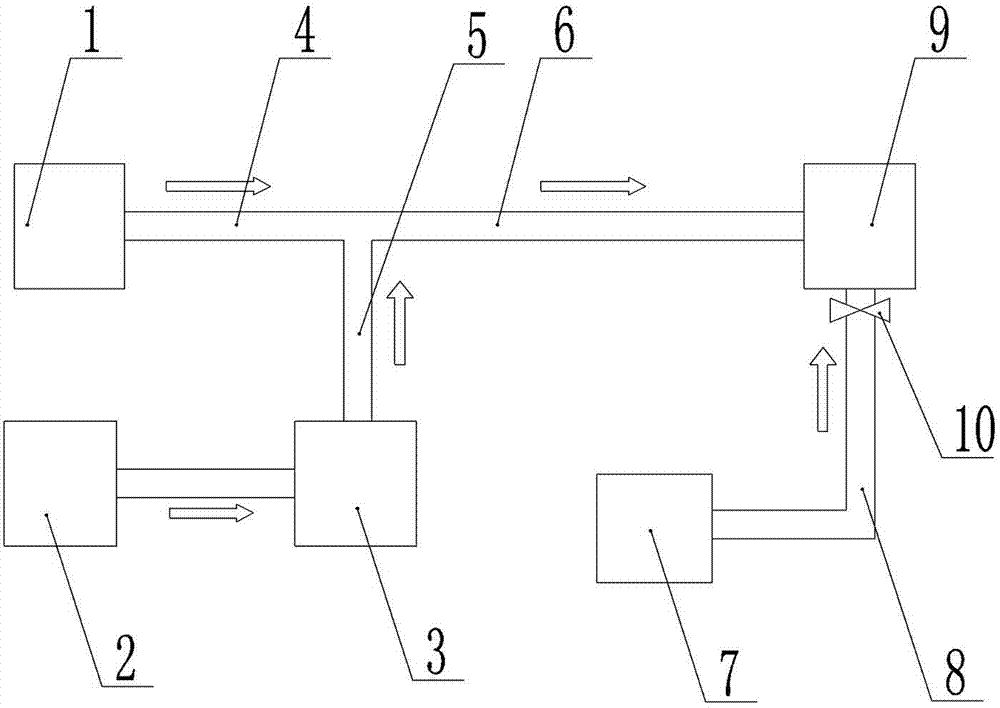

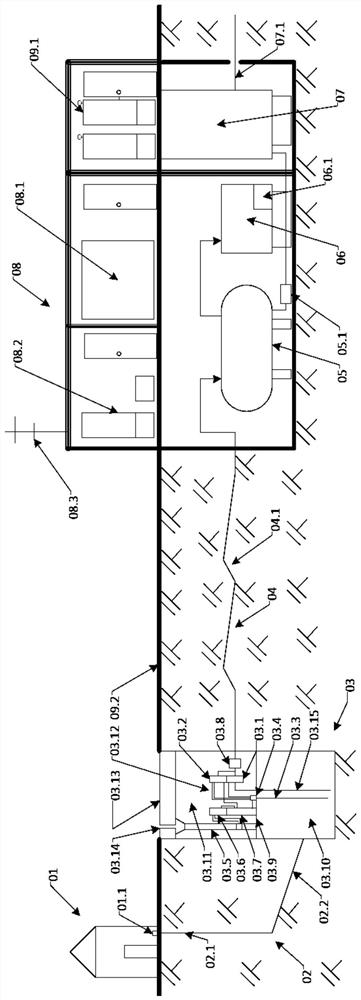

Vacuum sewage conveying system for crossing obstacles

PendingCN113145579AImprove conveying distance and conveying efficiencyReduce pipeline cloggingHollow article cleaningSewageControl valves

The invention relates to a vacuum sewage conveying system for crossing an obstacle. The vacuum sewage conveying system comprises a vacuum sewage pipeline penetrating through the lower side of the obstacle, an air pipeline and a ventilation pipeline which communicate with the vacuum sewage pipeline, valve assemblies mounted on the air pipeline and the ventilation pipeline, and a controller used for controlling the valve assemblies to act; one end of the air pipeline communicates with the vacuum sewage pipeline, and the other end extends above the ground; the ventilation pipeline communicates with the upstream end and the downstream end of the vacuum sewage pipeline. The vacuum sewage conveying system for crossing the obstacle relates to a specific technology for avoiding pipeline blockage caused by vacuum degree reduction and solid garbage precipitation in sewage when the sewage passes through the certain obstacle on the vacuum sewage pipeline, so that the conveying distance and the conveying efficiency of the vacuum sewage conveying system are improved, pipeline blockage is reduced to a certain extent, and the system reliability is improved.

Owner:清环拓达(苏州)环境科技有限公司

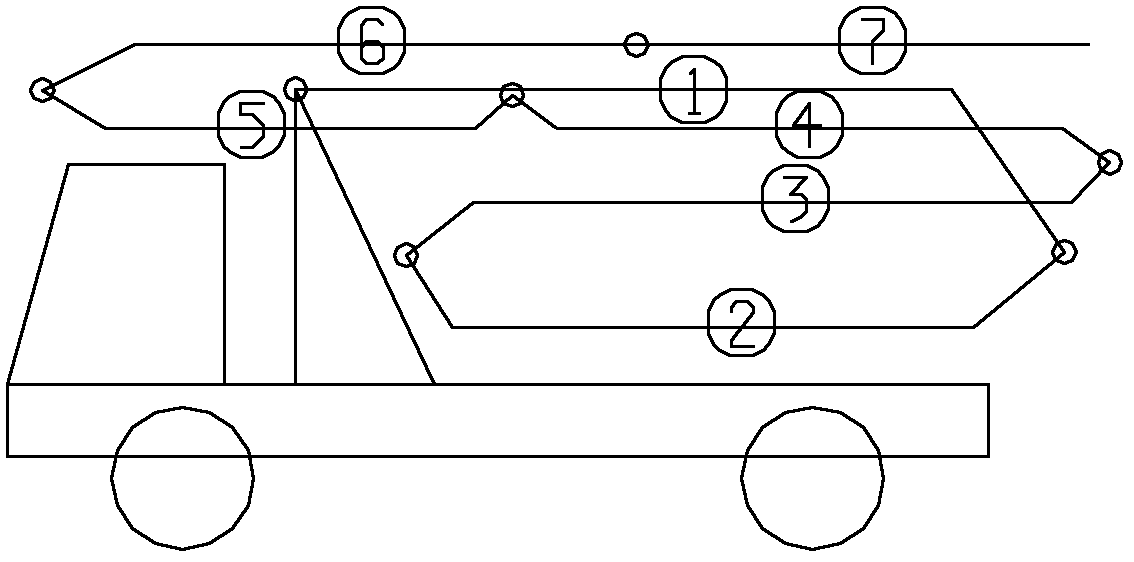

Concrete pump truck and arm support thereof

ActiveCN102518305BSmall sizeExtend the conveying distanceBuilding material handlingHoisting equipmentsOperabilityMechanical engineering

A boom of a concrete pump truck and a concrete pump truck having the boom. The boom has a folded state and an unfolded state, and comprises seven boom sections (1 to 7) hinged in sequence. When the boom is in the folded state, the seven boom sections (1 to 7) are basically arranged into five mutually staggered straight lines, and at least the last two boom sections (6, 7) are on the same straight line. Due to such configuration, the overall size of the boom sections can be greatly reduced, and the requirements of the road running condition can be easily met. In addition, when the boom is in the folded state, at least last two boom sections (6, 7) are on the same straight line; so that the flexibility and the operability of a boom fabric can be greatly improved.

Owner:ZOOMLION HEAVY IND CO LTD

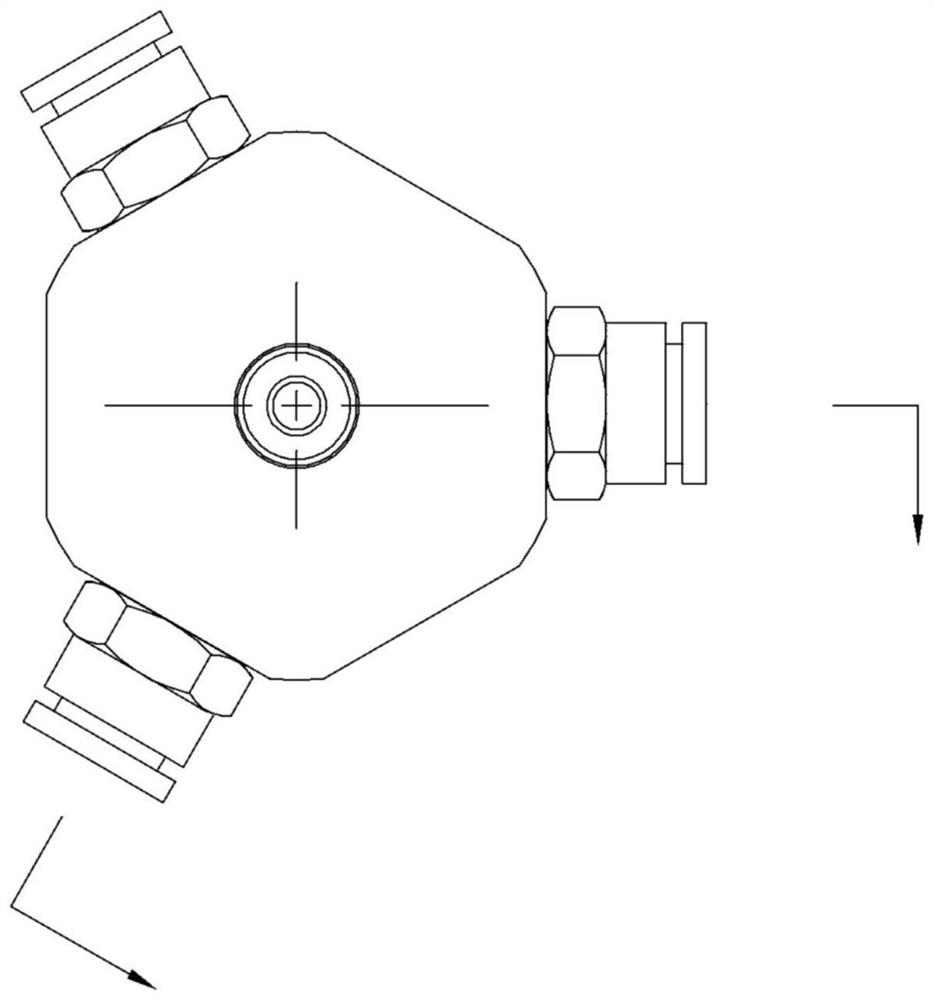

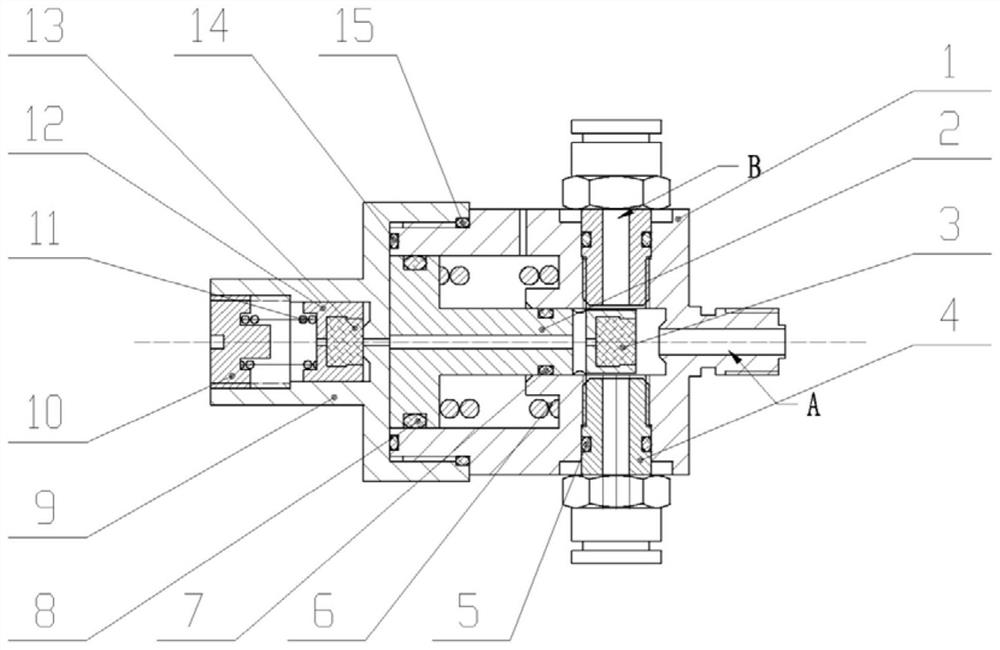

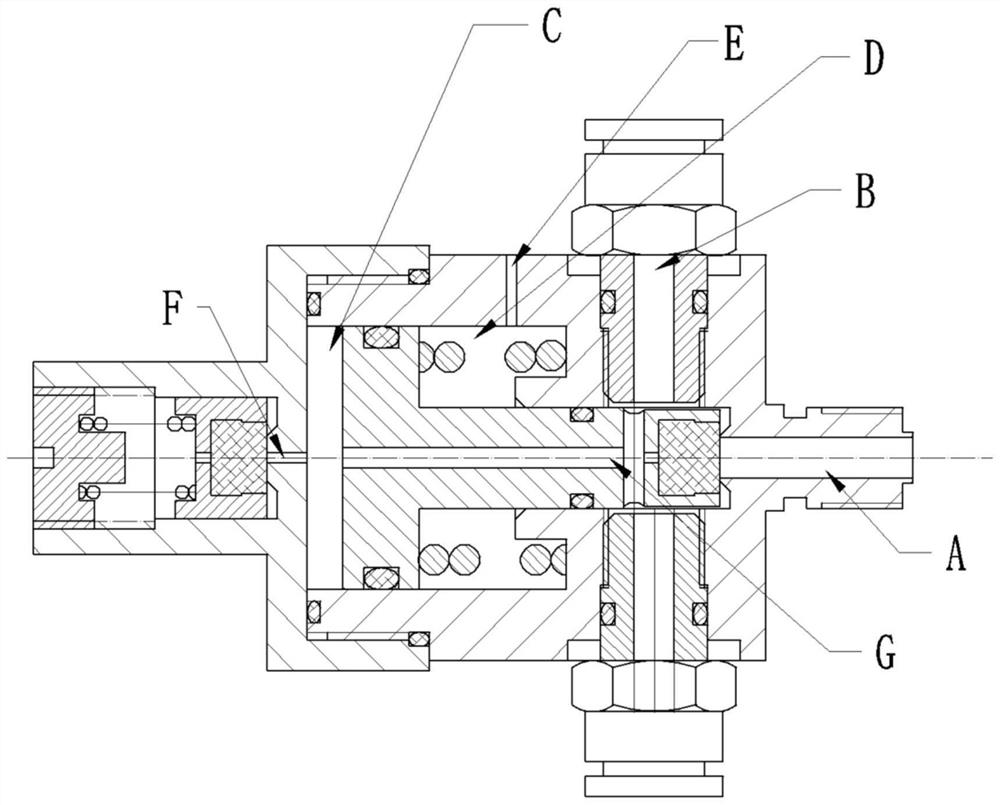

Pressure reducing and stabilizing valve

PendingCN111734853AIncrease storage pressureExtend the conveying distanceEqualizing valvesSafety valvesPhysicsEngineering

The invention discloses a pressure reducing and stabilizing valve. The pressure reducing and stabilizing valve comprises a valve body and a valve element mounted in the valve body, wherein a first endface sealing gasket is arranged in the position, at the upper end of the valve element, in the valve body; hose connectors are arranged on the two sides of the first end face sealing gasket; an O-shaped ring I is arranged on each hose connector; a first pressure adjusting spring is further arranged in the valve body; an O-shaped ring II is arranged on the front portion of the valve element; an O-shaped ring III is arranged on the rear portion of the valve element; the rear portion of the valve body is connected with a valve deck; a pressure adjusting base is embedded in the valve deck; a second pressure adjusting spring is arranged on the front side of the pressure adjusting base; the front end of the second pressure adjusting spring abuts against a second valve element; a second end facesealing gasket is arranged at the front end of the second valve element; and an O-shaped ring IV and an O-shaped ring V are sequentially arranged on the front portion of the inner end face of the valve deck. By arranging the external pressure reducing and stabilizing valve, the protection range of a fire detection pipe can be enlarged; through two-stage pressure adjusting, the upper pressure limit of the fire detection pipe is controlled, and the safety of hoses is ensured; and the utilization rate of a fire extinguishing device can be increased.

Owner:浙江蓝盾电工新材料科技有限公司 +1

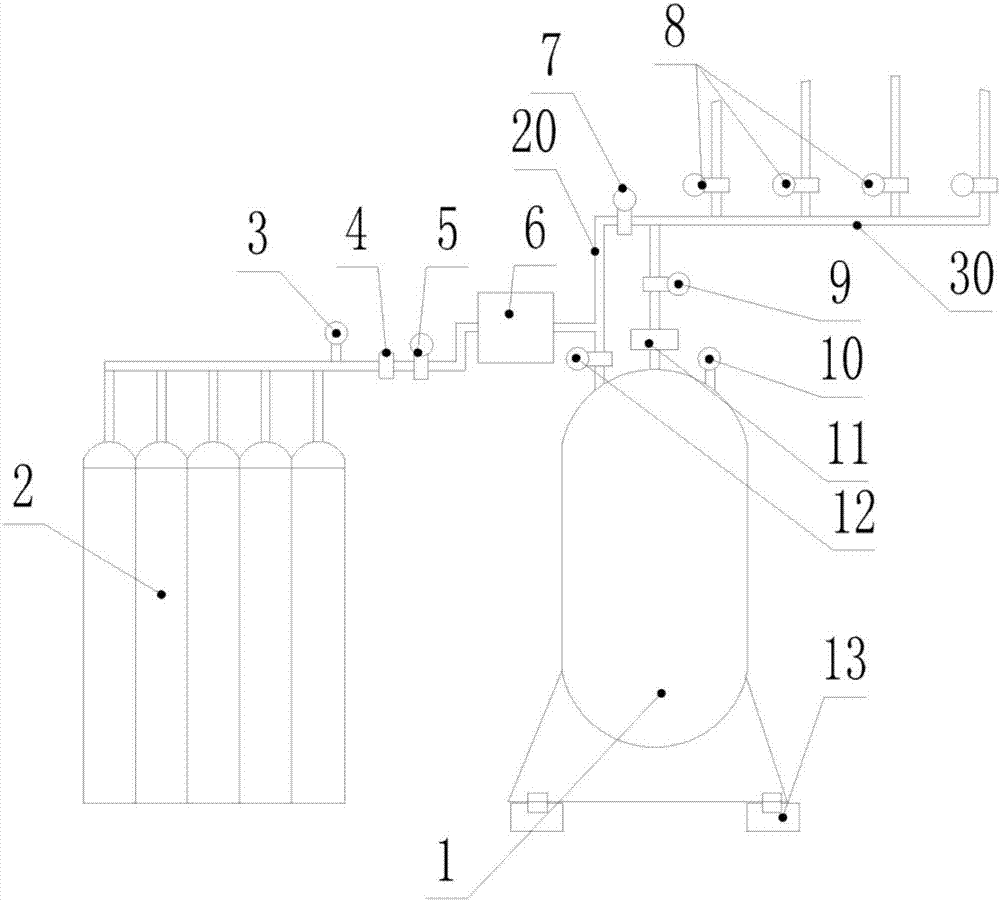

Heptafluoropropane fire extinguishing system

InactiveCN107080911ALong conveying distanceExtend the conveying distanceFire rescueControl systemEngineering

The invention relates to a heptafluoropropane fire extinguishing system. The heptafluoropropane fire extinguishing system comprises a fire extinguishing agent storing tank, the fire extinguishing agent storing tank is provided with a storing tank pressurizing control valve, the storing tank pressurizing control valve communicates with a pressurizing gas storing bottle assembly through a pressurizing gas pipeline, the fire extinguishing agent storing tank is further provided with a fire extinguishing agent releasing control valve, and a zone control valve is connected to the fire extinguishing agent releasing control valve through a fire extinguishing agent pipeline; a pipeline pressurizing control valve is arranged between the pressurizing gas pipeline and the fire extinguishing agent pipeline; the heptafluoropropane fire extinguishing system further comprises a control system, a weight detection device is arranged at the bottom of the fire extinguishing agent storing tank, and the control system is used for acquiring a signal of the weight detection device and controlling the fire extinguishing agent releasing control valve, the storing tank pressurizing control valve and the pipeline pressurizing control valve to be switched on and switched off. According to the heptafluoropropane fire extinguishing system, the weight detection device is used for monitoring the releasing amount of a fire extinguishing agent, and therefore the fire extinguishing system can achieve precise and quantitative releasing, has the higher usability and can flexibly distribute the fire extinguishing agent; meanwhile, the pipeline pressurizing control valve is arranged, and therefore it is guaranteed that the fire extinguishing agent can achieve the longer conveying distance.

Owner:太仓苏安消防设备有限公司

Novel fork-arm type vehicle-mounted air purification device

The invention provides a novel fork-arm type vehicle-mounted air purification device. The device is provided with a fork-arm type air flow channel, an emission head and an adjustable air outlet. One or more functional modules, such as an anion (plasma) generator module, an electronic dust removal module, an electronic smoke removal module, an electronic sterilization module, an electronic fragrance module and an electronic odor removal module, can be freely carried, and a unified and flexible physical structure is formed and is suitable for various vehicles. A fork arm is a hollow guide pipe which is bendable or retractable, and wires are integrated in the fork arm. The emission head is internally provided with an ion electrode or an atomizing sprayer, and a blower device is integrated with the emission head, so that ions or fragrance or a functional liquid is sprayed into air in the vehicles. The fork-arm type vehicle-mounted air purification device is compact in structure, low in weight and convenient to install. The device can be installed on the backs of center rearview mirrors of the vehicles or on the inner surface of rear windshields of the vehicles, and the height is beneficial to sufficient, uniform release of the ions or fragrance or other functional liquids. The angle is adjusted through a bendable support, and the sight is not affected.

Owner:威斯巴特科技(宁波)有限公司

A multi-channel optical cable bundle tube

ActiveCN109581604BExtend the conveying distanceReduce frictionOptical fibre/cable installationFibre mechanical structuresMechanical engineeringLubricant

The invention belongs to the field of bundle tubes, and in particular relates to a multi-channel optical cable bundle tube, which includes a protective cover, a solid columnar body is arranged inside the protective cover, and a reinforcement cavity is arranged at the center of the solid columnar body along its axial direction. There is a tensile tube, and there are multiple optical cable placement cavities evenly distributed around the reinforcement cavity. There is a lubrication cavity between two adjacent optical cable storage cavities. The lubrication cavity is connected with the optical cable storage cavity through multiple infusion channels. There is a lubricant used to reduce the friction between the optical cable and the cavity where the optical cable is placed. A reinforcement tube is fixedly connected to the side wall of the lubrication cavity away from the reinforcement cavity. The other end of the reinforcement tube penetrates radially to the outside along the solid cylindrical body. On the protective cover A connecting pipe corresponding to the position of the reinforcing pipe is provided. The invention can overflow the lubricant in the whole process by setting the lubricating cavity, reduce the friction force between the optical cable and the optical cable placement cavity, increase the conveying distance, and thus improve the laying efficiency.

Owner:武汉齐力得管业有限公司

Novel multifunctional sludge heat pump drying machine

ActiveCN114315087AKeep dryExtend the conveying distanceSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesThermodynamicsSludge

The invention relates to a novel multifunctional sludge heat pump drying machine, and belongs to the field of sludge drying machines, the novel multifunctional sludge heat pump drying machine comprises a drying box main body, a ventilation system bearing box, a feed inlet and a discharge mechanism, a first drying box conveying belt, a second drying box conveying belt and a third drying box conveying belt are arranged in the drying box body, the bottoms of the ventilation system bearing box and the drying box body are fixedly connected with bottom supporting frames, and the bottom supporting frames are fixedly connected to the supporting table. According to the novel multifunctional sludge heat pump drying machine, it is guaranteed that the heating capacity of sludge in the drying box body is good, heating is uniform, the sludge drying effect is good, intermittent discharging can be carried out when dried sludge is discharged, the dried sludge forms pile-by-pile finished products to be discharged, and the drying efficiency is improved. Finally, workers can conveniently collect and package the dried sludge finished product.

Owner:中煤(北京)环保股份有限公司

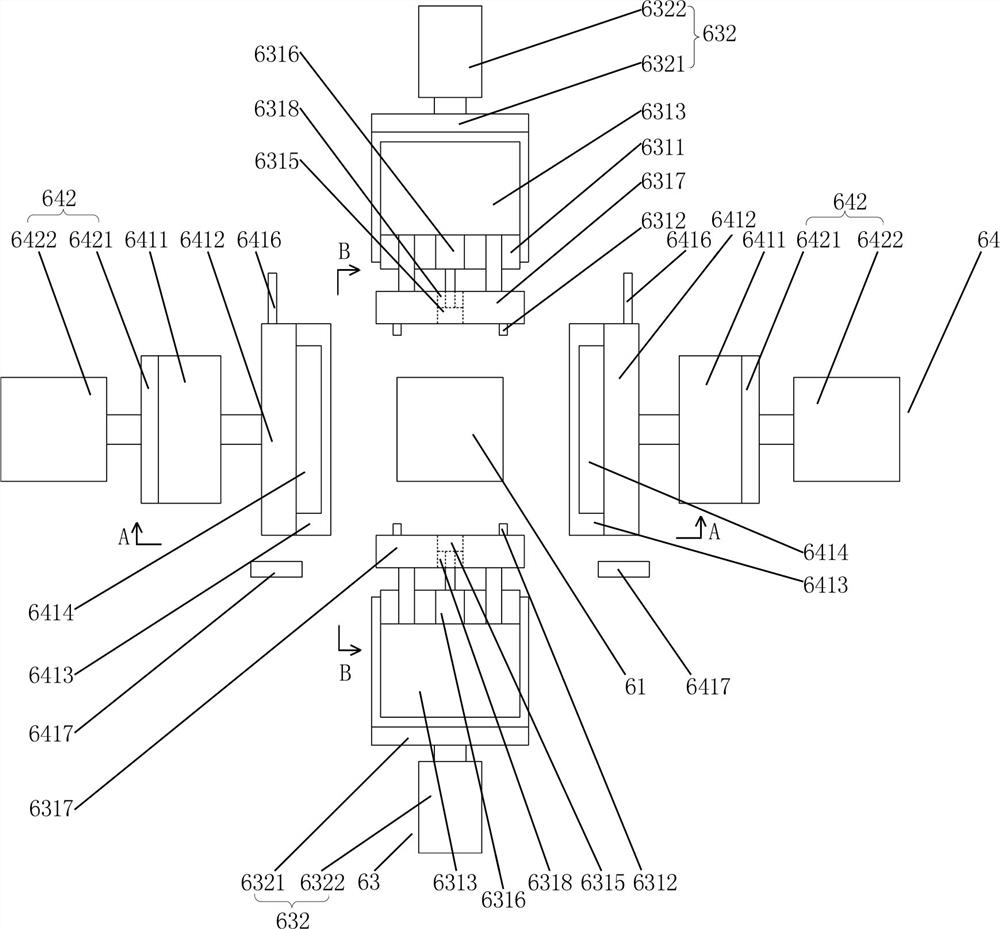

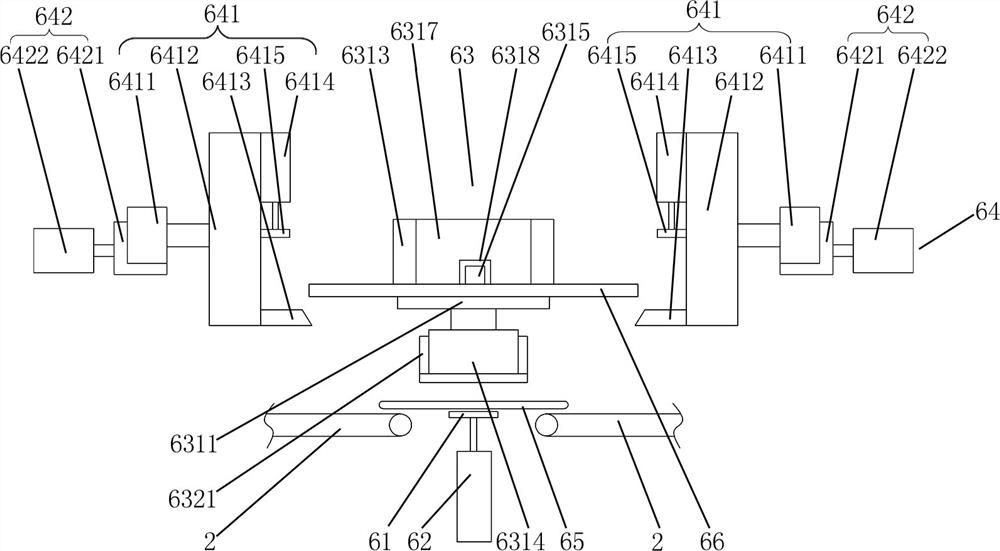

Ceramic chip electrode printing machine

ActiveCN114211871AInhibit sheddingSmooth flipRotary pressesConveyor partsStructural engineeringBrush device

The invention relates to a ceramic chip electrode printing machine which comprises a rack, a conveying mechanism, a primary brushing device, a primary drying device, a plate turning device, a secondary brushing device and a secondary drying device. The plate turning device comprises a plate lifting table, a plate lifting mechanism, a double-side clamping and supporting mechanism and a double-side clamping and turning mechanism; the double-side clamping and supporting mechanism and the double-side clamping and overturning mechanism are both located above the plate lifting table. The double-side clamping and supporting mechanism comprises two supporting assemblies which are oppositely arranged in the left-right direction and a first clamping driving mechanism capable of driving the two supporting assemblies to move in the opposite direction or in the back-to-back direction. The double-side clamping and overturning mechanism comprises two overturning assemblies which are oppositely arranged front and back, and a second clamping driving mechanism capable of driving the two overturning assemblies to move in the opposite directions or in the opposite directions. The ceramic chip electrode printing machine has good stability when the ceramic chip is overturned, the ceramic chip can be prevented from falling off in the plate overturning process, and smooth overturning of the ceramic chip is ensured.

Owner:汕头市瑞升电子有限公司

Compressed air assisted airless pressure spraying premixing granulation equipment and binding material spraying system

ActiveCN112570176ASpray evenlyConvey evenlySolid waste managementLiquid spraying apparatusHydraulic pumpEngineering

The invention provides compressed air assisted airless pressure spraying premixing granulation equipment and a binding material spraying system, which are applied to binding material spraying. The premixing granulation equipment comprises an airless pressure spraying device and a compressed air assisted granulation device, wherein the airless pressure spraying device comprises a spraying hopper and a hydraulic pumping device connected to the spraying hopper through a high-pressure pipeline; an airless pressure spraying sleeve head is connected to the bottom of the spraying hopper; a pluralityof airless pressure spraying holes are arranged in the bottom of the airless pressure spraying sleeve head; the compressed air assisted granulation device comprises a granulation cavity and an auxiliary air compressor connected to the granulation cavity; the airless pressure spraying sleeve head is located in the granulation cavity; the granulation cavity is cylindrical; cable-stayed fixing bladesare arranged on the inner wall of the granulation cavity; and compressed air in the granulation cavity forms a tangential airflow field under the action of the cable-stayed fixing blades. According to the compressed air assisted airless pressure spraying premixing granulation equipment and the binding material spraying system, the granulation effect, the jet density, the conveying distance, the spraying range and the spraying uniformity of the technology are uniformly improved in the radial direction of the fluid.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com